Parafield Poultry Station

Parafield Poultry Station was established in 1911 and operated by the South Australian Department of Agriculture, until its closure in 1996. During this period it was a primary national centre for the research, development, and extension of poultry technology for both the egg and poultry meat industries.

The management and staff played a key role in selecting and introducing new breeding lines and equipment, improving poultry nutrition and productivity, pioneering new housing technology, improving egg handling and marketing techniques, facilitating the development of key industry organisations, and by training advisory staff, for the betterment of the industry in general.

This article is an attempt to assemble, in chronological order, information about the range of functions and activities as they occurred at Parafield Poultry Station.

Cutting the hay

Establishment of Parafield Poultry Station

Parafield Poultry Station, later to become known as Parafield Poultry Research Centre, was established on Section 2235, Hundred of Yatala, at Parafield, near the township of Salisbury, in 1911.

Section 2235 formed part of a total area of 43 hectares (104 acres) which had previously been developed as a wheat breeding farm by the Department of Agriculture.

An article written by the Special Reporter for “The Register” at that time includes the following:

“Waving wheat and fallow; new fences, trimmed hedges, open spaces; implements, stables – these things represent energy and suggest more thinking and more energy. The field of investigation is an ever widening one. You reach one goal and another looms in view. You reach that one and finality mocks like a mirage in the desert. The genuine experimentalist never marks time. His business is to keep marching, to be always at the front in his campaign against big agricultural problems.”

True to those words, the property had proven to be too small for the purpose of wheat breeding and the enterprise was relocated at Turretfield.

At that time all South Australian poultry breeding and experimental work was being conducted at Roseworthy, Kybybolite and Murray Bridge Research Centres. These centres were rather isolated, and remote from the main areas of poultry production, and it was agreed that a single dedicated site in a more central area, devoted entirely to poultry research and experimental work, would be a major advantage to the poultry industry.

Consequently, the Parafield site was transferred to the Poultry Division and became the centre for experimental and research work and for demonstration purposes which continued for the ensuing 85 years.

Duncan Forbes Laurie, who was appointed to a newly created position of Government Poultry Expert within the Department of Agriculture in 1905, took charge of the development, and Walter Reynolds Day, formerly Superintendent of Poultry at Roseworthy Agricultural College, was appointed Farm Manager.

The beginning

The first report relating to the development of the Parafield Poultry Station covered the period from its establishment at some time in 1911, to June 30th, 1913. The report provided a lengthy description of proceedings to that date, and included, in part, the following:

“The barn, an excellent structure, has been altered to serve as incubator rooms."

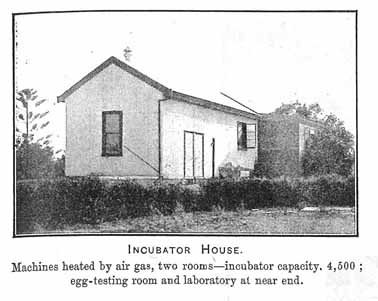

Incubator House

Adjoining these incubator rooms is an excellent and sufficiently equipped laboratory. In addition to various chemical equipments the scientific impedimenta of the poultry section include the following, which permit of exact results. A Zeiss large microscope of the latest pattern with a full battery of objectives, dry and oil immersion, of the highest and also very low powers; achromatic eyepieces, also a full set of compensating eyepieces. The microscope has micrometer movement for use with the camera, a very powerful Abbe condenser, and the latest improved mechanical stage. A less elaborate microscope, more portable than the large one, serves for rough identifications etc. A latest pattern Zeiss photo- micrographic camera for horizontal and vertical work, with apparatus for focussing with micrometer movement, condensers, screens, and incandescent light for more intense work, and a hand camera for outside work are available. Zeiss and other callipers, and a complete surgical outfit for dissection, post-mortem work, etc. are available, so that careful examinations can thus be made if any disease is suspected.

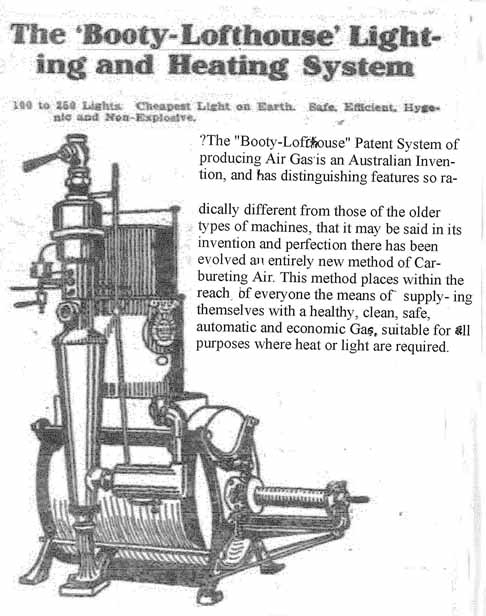

The incubator rooms and brooder houses are supplied with gas generated by a Booty-Lofthouse petrol gas plant.

In the larger room are 16 No1 Cyphers hot air incubators, each of 140 egg capacity, placed back to back, and supplied by flexible tubes and Bunsen burners from a main lying along the floor under the machines.

Cyphers Hot Air Incubator.

This arrangement is, in effect, a mammoth incubator of 2,240 egg capacity. In the other room are more Cyphers incubators of from 60 to 390 egg capacity.

A third room on a different pattern will be erected to contain various machines of different makes, and, for contrast, these will be heated with kerosene. The total capacity of the incubators in use is well over 4,200 eggs.

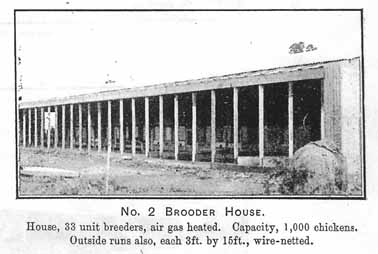

Two brooder houses each 100ft. long x 17ft wide are in course of erection. One of these has a large store 100ft x 17ft at the rear. The brooder house is fitted with 25 Cyphers hovers, and has, for each hover, an inside run 12ft x 4ft with low glass wind screen and netted run 4ft x 15ft.

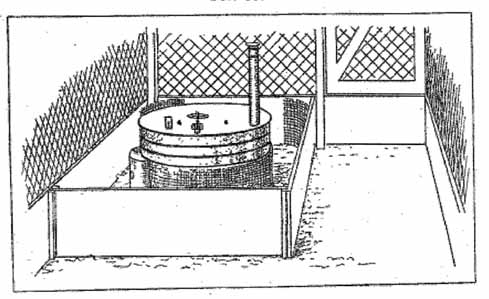

The Cyphers Hover Brooder, as originally installed.

There are only laying strains of White Leghorn and Barred Plymouth Rocks on the station.

White Leghorn cock.

White Leghorn hen.

The breeding pens, of which there will be about 200 ultimately, are built on the continuous system. Each house has 9ft x 5ft floor space with an outside run 9ftx 40ft. These pens will accommodate 3,360 laying hens for breeding purposes. Further accommodation will be erected to provide for a total of about 5,000 layers, besides the breeding stock.

About 600 single testing pens, each with a house 3ft square and run 3ft x 20ft built on the continuous system will be provided.

Barred Plymouth Rock cock.

Barred Plymouth Rock hen.

In addition to the large grain and food store, there are three other food houses, a workshop; engine, mill, and chaff cutting room; hay shed etc. The whole will take some months to complete, and it is hoped, will include a hall for lectures etc.

The main points in the system may be thus summarised; - Good housing, clean yards and plenty of scratching litter. Scientifically bred, sound stock will be fed on proper foods of the best description. Good sanitation from the breeding yards, through the incubators and brooder houses, chicken rearing yards, and back to the adult stage.

No hen under two seasons old is used as a breeder. All White Leghorns are tested before breeding. Farmers and others are supplied with reliable breeding stock at fair rates. No inferior stock is either on hand or sold. Eggs, chickens and young stock are sold when available. All eggs marketed are clean-shelled, graded and packed in standard crates.

The demand for stock is greater than the available supply. For revenue and experimental work a large number of birds must be bred annually, and they must all be of known parentage”.

Drought

The official report for the year ending June 30, 1914 was rather sombre for the season proved to be abnormally dry. It reads, in part as follows:

“As it was intended to grow a considerable portion of the grain and green food used in feeding the birds, it was hoped that the opening of the Station would be heralded by a bounteous crop. However, the hay crop was disastrously light, averaging under 15 cwt. to the acre. The wheat suffered from the ravages of the sparrows and averaged about 10 bushels and a poor sample, whilst from the small area of peas sown, the results were not encouraging. It was not until the Lucerne was irrigated that an adequate supply was assured.

Whilst Barossa water is laid on, it proves too costly for irrigation and approval has been obtained for seeking a sub-artesian supply. In regard to new buildings, the utmost economy was required in view of the money available for material and labour. The large block of single testing pens is not complete, but enough accommodation is available for sections 3 and 4 of the laying competition and also a large number of Poultry Station pullets. Both brooder houses are completed and similar in design.

The brooding results were satisfactory and the year ended with 1700 pullets, chiefly White Leghorns and Barred Plymouth Rocks; and over 300 strong, hardy chickens seven to eight weeks old.

The interest in the Station evinced by breeders and general public is tribute to the wisdom of concentrating all experimental poultry work at such a convenient centre. The Station is open to the public on the first Wednesday and fourth Saturday of each month. Several special visits were organised and were so well attended that the numbers were almost unwieldy.

During the year approval was given to install a Mammoth Incubator. After receiving plans and specifications for various styles of incubators, it was decided that Mr D Lanyon of Kent Town should be commissioned to construct the machine. In due course the large incubator, of over 5000 eggs capacity, was finished and was included in the poultry section of the Departmental Exhibit at the Royal Agricultural and Horticultural, March Show 1914. A successful trial hatch, under very trying conditions was made, and it is now intended to erect a special room at Parafield and install the machine forthwith.

Various newspaper articles written throughout the year include references which are of interest.

“Parafield is the largest official poultry station in the world and its purpose is to provide an authoritative object lesson in the brooding, housing and feeding of poultry, to demonstrate how a big commercial poultry business should be conducted; and to facilitate investigational work in connection with poultry raising and disease control.”

“It is confidently expected that the revenue earned at Parafield will more than suffice to meet expenses and the interest on capital”.

Professor Bateson of the UK, who visited the station with other members of the British Science Association, was immensely impressed by the soundness and completeness of the work being done. He invited Mr Laurie to contribute a series of articles to “The Journal of Genetics” describing the system, together with the results recorded to date. These results embody practical illustrations of the laws of inheritance relative to the number and size of eggs laid, the size of fowls, broodiness and egg shell colour.

Professor William Bateson, later Dr William Bateson, a Fellow of St Johns College, Cambridge UK, was reported to be the first person to use the term “genetics” to describe the study of heredity and biological inheritance. He was elected a Fellow of The Royal Society in 1894, and won the Darwin Medal in 1904.

Early progress

The annual report for the year ending June 30, 1915, reveals a time of great activity, with good progress made in various directions.

“The Mammoth Incubator of 5000 eggs capacity was installed in a new building specially erected for its accommodation, and a new heating system, fired by a coke burning oven, was installed.

The results were, in every way, satisfactory and the costs in regard to labour and heating were reduced to a minimum. All danger of fire was eliminated and there were no noxious gases or disagreeable fumes emitted. Alterations to the brooder houses were made to accommodate the coke-heated system, which again permitted great savings to be made.

A new row of chicken rearing yards, 50 in number, was completed, and 18 additional breeding yards were added.

A patent automatic watering system was installed in the single testing yards and was the means of saving much labour. There were over 500 pullets undergoing a year’s test in these yards. This block of yards will be completed shortly and will include 66 pens set apart for investigating several important matters connected with breeding, including single mating and fertility tests. This block of single testing and breed testing pens is without equal.”

To Salisbury – the weekly shopping.

Water supply

A bore was sunk and an excellent supply of water was obtained 107 feet from the surface. The analysis shows only 57 grains per gallon of mineral salts. A centrifugal pump delivers 2,500 gallons an hour to an overhead tank or to flumes for irrigation.

Green food supply

About 5 acres have been cultivated and sown with Lucerne and ½ acre sown with berseem which gave excellent results. During the ensuing year a fresh plot will be sown with lucerne and berseem.

It is proposed to store a large quantity of lucerne hay, which will be chaffed and ground for use as poultry food. Any surplus will be available for city and suburban poultry breeders.

Crops

At the present time there are under crop about 70 acres of wheat, barley and oats and the appearance points to a good yield.

Machinery

A suitable shed was erected in which were installed the 8hp Carter petrol engine and other machinery. The engine drives the Boss centrifugal pump on the bore, a chaffcutter, and a Kelly duplex mill for grinding cereals and lucerne.

Infrastructure

The stable was remodelled and accommodates seven horses and a shed for farm vehicles was also built.

The poultry

The breeds currently stocked are White Leghorns, which predominate; a few hundred Barred Plymouth Rocks and a strain of good White Wyandottes. Much interest has been shown recently in the Rhode Island Red breed and a commercial strain of these birds is being developed from three good blood lines.

Rhode Island Reds

On the 30th June 1915, there were 2,742 adult birds and 5,465 chickens on hand. The very high cost of foodstuffs renders it out of the question to fully stock the plant at present.

During the year 381 female and 115 male birds, all of high class stock, were sold to farmers and breeders. In addition, 84 sittings of eggs from stud stock were sold.

Mr Laurie also advised that “without doubt, the system of breeding advocated by me at Parafield is giving excellent results.”

The Annual Report for the year ending 30th June 1916 reveals that “consequent upon financial stringency”, operations at the Poultry Station were on a much reduced scale. However, with the funds and labour available every effort was made to continue with the improvements.

Government institutions and hospitals were supplied with eggs of the highest quality.

A large number of breeding stock and numerous sittings of eggs were sold.

The supply of water was not sufficient for requirements, despite the practice of night overhead irrigation.

The crops were very good. The results from 76 acres were 1270 bush wheat, 50 tons of hay, 100 tons of straw, and about 3,800 cub.ft. of cocky chaff.

The stock on hand at June 30th included 3,450 adult birds and 2,094 chickens.

White Wyandotte cock.

White Wyandotte hen.

The farm manager

For the year ending 30th June 1917, similar stringencies had to be observed. However, it is most likely that these measures heralded a more realistic approach to poultry housing in general, and the stocking density in all age groups was increased. The official report states that “the capacity of the plant has been doubled without incurring expense for new material. The brooder houses have been remodelled, and are now most effective. The problem of successfully rearing large numbers of chickens has been solved. The main object in effecting the various alterations is to lower costs of production and to attain greater efficiency”.

Mr Laurie also reported that Mr A R M Basford had been appointed as the Working Superintendent, of Parafield Poultry Station.

He also advised that breeding stock and eggs for hatching had been sold in satisfactory numbers, and that “much is heard nowadays of the advantages of dry mash feeding”. However, the Poultry Expert was not to be swayed, and the daily Wet Mash system ruled supreme at Parafield for many years.

Unfortunately, no record of the work performed by Mr Day who was appointed as the first Farm Manager at Parafield has been found. Mr Laurie claimed full and complete credit for everything done and every decision made, whether in farming, building, husbandry, stock selection or choice of equipment.

However, an article in the Sunday Mail of Saturday 23rd June 1917 reveals that Mr W R Day, formerly manager of the Parafield Poultry Station, had been appointed Manager of the Bronzewing Poultry Farm. This farm had been established on 30 acres of scrub land at Plympton which was purchased in 1913. By the 23rd June 1917 it had been developed into a thriving enterprise with housing for 6,000 laying and breeding hens, six large runs for turkeys and a large area for ducks. Incubators, with a capacity of 6ooo eggs, had been installed. Five acres had been set aside for cultivation and a bore 247 feet deep had been sunk. This bore overflowed at the rate of 2,500 gallons an hour 3 feet above the surface. The breeds of poultry kept were White Leghorn, White Orpington, and White Wyandotte fowls, Pekin ducks and Bronzewing turkeys.

Bronzewing turkeys, 1950.

Further references reveal that in 1918 W R Day was instrumental in establishing a branch of the National Utility Poultry Breeders Association, commonly known as the NUPBA in South Australia. He was elected chairman of a Special Meeting of the National Utility Poultry Breeders Association of New South Wales, which was held in the Brookman Hall, School of Mines Building, North Terrace, Adelaide, when a proposition to establish a South Australian Branch was carried unanimously. Following that meeting, the South Australian Branch was formed and W R Day was elected as Chairman. In later years, egg laying tests on behalf of NUPBA members were carried out at Parafield, and these continued into the 1980s.

Problems solved

In his 1918 report Mr Laurie states that it was decided to develop the Poultry Station on commercial lines and as a means of demonstrating modern methods. He reported that “the housing and other plant is considered by competent judges to be the finest in Australasia, and the methods in vogue have met with very general approval”.

Another smaller Mammoth Incubator was installed making the total incubator capacity 8,500 eggs. “These incubators have worked well and the cost of hatching and rearing and the splendid results in the brooder houses and chicken rearing plant, permit me to say that the problems of hatching and rearing, breeding, feeding and housing on a very large scale have been most thoroughly solved at Parafield”.

Caponising experiments were conducted and proved conclusively that this is not a profitable practice.

On June 30th, 1918 the following birds were on hand – 3,321 adult stock and 4,425 chickens.

The 1918-1919 season was not good and the crop was “very indifferent”, consequently, there was practically no hay and a great shortage of straw. However, the yield of green fodder was excellent, particularly lucerne.

The spring hatching operations were very successful and a large number of chickens were hatched and reared. It was proposed, that as soon as funds were available, a modern fattening plant would be erected at Parafield.

However, that venture did not materialize, and experimental work on poultry meat production was not resumed until the late 1950s.

In September 1918, the Adelaide Infertile Egg Association held its inaugural meeting and Mr C F Anderson, who was Mr Laurie’s trusted assistant, was elected Secretary. The Association was comprised of members who agreed to sell only infertile eggs, each of which was branded with the member’s number and guaranteed to be of good quality and infertile. In his annual report, Mr Laurie described this as the most important event of the year and reported that “the Minister considerably assisted this good work by agreeing to Parafield Poultry Station becoming a member”. This Association later became known as “The Red Comb Egg Association” and had a long connection with Parafield Poultry Station, which conducted a Single Test Egg Laying Competition on its behalf for many years. Mr Anderson continued this alliance throughout the following years, and finally, as the result of much lobbying by members of the Association, fellow egg producers, and the public generally, the “Marketing of Eggs Act 1941” was legislated by the South Australian Government.

Red Comb Egg Association at the 1974 field day.

Breeder selection

In his report for the year ending June 30th 1920, the Poultry Expert states that “several minor additions made during the year have practically completed the plant. The single test pens have been completed and all runs protected by a thatched roof. The block is of 10 rows, each of 66 single pens. The total, 660, constitutes the largest block of single test pens in the world. There are well over 1,300 gates in the block”

It was also reported that “most of the road making had been finished and paths gravelled”.

An ample supply of straw and greenfeed was produced. Two lines of Skinner overhead irrigation have been installed, so that there are now three lines each 504 feet long, and each line waters 0.58 acres. Portable Skinner pipes, suspended Skinner and a large 130 ft. span revolving “Rainmaker” afford water supply to about 6 acres of greenfeed crops’.

These details are followed by a very complete description of selection criteria which emphasises breed characteristics as being of equal or even greater importance than egg production, and the following details are quoted from Mr Laurie’s annual report.

“Following the single-test method of breeding, a system of rigid selection is continued in building up the breeding stock. In White Leghorns, the sprigged-comb runts, so much admired by some people, are conspicuous by their absence. Birds are bred with due regard to standard and breed characteristics. Due regard to size has been a prominent factor in selection for some years. The results are now seen in the steady improvement each year. The sprig comb has almost disappeared, and the tinted egg-shell is very rarely seen. Stamina is a leading character of the stud birds. At present the following three breeds are proving satisfactory; the White Leghorn, Barred Plymouth Rock and Black Orpington.

The Rhode Island Red has been discarded. As a fancier’s fowl, it affords ample scope for the breeder. As an economical fowl, it is too much trouble to breed. Colour is more esteemed by exhibitors than other more useful points. The red colour of the Rhode Island Red depends upon a due proportion of black pigment. If insufficient the progeny are too light, and then become mealy and with white feathers. Too much black pigment makes its appearance in the form of black markings, and even wholly black feathers. In a commercial flock one needs an easily attained uniformity of type, colour, and markings.

The Barred Rock I consider a useful breed, better for table-bird production, than as a layer. It breeds very true to type and markings, and the chicks are hardy and grow quickly, and, as table birds, good prices are generally the rule.

The Black Orpington, at Parafield, is not the undersized black bird – often masquerading as a laying strain Black Orpington – nor is it the heavily-feathered, coarse show type. There was a happy medium some years ago which agreed closely with the standard of perfection. This was the handsome and useful type which made the breed so popular. It must always be remembered that the Orpington was introduced as a fair layer and a good table fowl. The endeavour to outpace the Leghorn as a layer without losing the table bird qualities may appear quite an easy matter to accomplish, yet time will show another exploded fallacy.

The Black Orpington can never rank in the first flight of table bird breeds, but it is a useful one, especially in the Australian markets. It is noted that the prominent laying strains are usually of small size – smaller than the original useful type. It is not a difficult matter to build up a strain of true Orpingtons showing fair size without coarseness, and yet a good layer. Properly bred, the Black Orpington is an excellent commercial breed, but must be handled carefully."

Black Orpington cock.

Black Orpington hen.

It should be noted that the “undersized black bird” to which Mr Laurie refers in the previous paragraph was and still is known in Australia as the Australorp, which, with the White Leghorn and Rhode Island Red became the dominant breeds used commercially in Australia. The lengthy descriptions also suggest that Mr Laurie considered breed characteristics to be of greater importance than egg production in the selection process, and may explain the somewhat frosty relationship that appears to have existed between himself and W R Day who obviously favoured the utility side of breeding and selection, as his interest in the NUPBA indicates.

Also of interest in this report, is that a motor cycle was purchased, so that Mr Laurie’s assistant, Mr Anderson, could visit all suburban and many country breeders.

Australorp cock. Source: Australorp Club of Australia https://www.australorps.com/18.html

Australorp hen. Source: Australorp Club of Australia https://www.australorps.com/18.html

Reports for the following 2 years reveal that “housing experiments have failed to show any benefits of newer styles over our original designs”.

With regard to incubation, “continued work on the old lines has given the greatest satisfaction, and will be continued”.

The 1923 report confirms that “Parafield has ceased to be an Experimental Poultry Station, and in future will be conducted as a “Demonstration Poultry Station” on commercial lines. Mr CF Anderson, who, “for 14 years had been in the Adelaide office and had assiduously helped Mr Laurie and been fully trained by him in the various duties of visiting and inspecting”, was appointed as Farm Manager at Parafield.

In future it is intended to stock about 2000 White Leghorn breeding hens, suitably mated, in addition to 3000 White Leghorns for market egg production. Some heavy breeds will be given a trial.

Farming operations will be discontinued and the area occupied as a poultry station will be very much less than formerly.

Single Test Pens.

Reaching out

A brief report by Mr Laurie in 1924 confirmed that the “Experimental Poultry Station’ had been transformed into a ‘Commercial Demonstration Station’, with the necessary alterations still in progress”.

Details of this work were highlighted in his report for the year ending June 30, 1925, when he reported that much of the housing had been extended and modified. Perhaps the most startling revelation for this, and any other year, was that the large block of single test pens designed by Mr Laurie and completed in 1920, have now been demolished and replaced by “fine corridor type houses” When completed accommodation for 6,000 adult birds would be available.

Another item of interest was that the Minister had approved of “Parafield being made available for taking students desirous of taking training in Poultry Farming. Accommodation would be provided for students to live on the farm”. However, no record of such action having been taken has been found.

During the 1926 season it was, once again, decided to change the heating system. The coke heated boilers were replaced with kerosene heated boilers, and once again, this proved to be very satisfactory.

The reports for 1928 and 1929 were submitted by Mr Anderson, who claimed that Parafield had set the standard for practically all the plants constructed for commercial egg production in South Australia.

He also advised that the Department had agreed to conduct an egg-laying competition on behalf of and for the Red Comb Egg Association of South Australia, at Parafield. In return for attending to the birds and keeping all records Parafield would benefit from all eggs laid during the period. The association proceeded with the erection of 243 single test pens for the purpose. This capacity was later increased, and by 1949 a total of 750 pens were available for competition purposes.

Mr Laurie retired on March 31, 1930 and finally it could be claimed that Parafield Poultry Station had been established. For 19 years, many grandiose schemes and world first inventions, for which Mr Laurie claimed full title, had been tried and mostly discarded. However, the final result was a functional demonstration unit which served the poultry industry extremely well for many years.

Mr CFP Anderson was appointed Government Poultry Expert in December 1930. He also retained the position of Manager at Parafield Poultry Station. He represented South Australia at Federal Conferences related to poultry management, with particular emphasis on egg marketing, in 1925, and on several subsequent occasions. He was the founding secretary of the Red Comb Egg Association of South Australia, which was formed in 1918, and grew to 400 members pooling 90,000 doz. eggs weekly in 1930. Mr Anderson remained the secretary throughout that period.

A rapidly increasing demand for adult stock, fertile eggs and day old chickens during the next few years greatly exceeded the supply, which was restricted to recognised poultry breeders only. The system of ‘battery brooding’ in which chickens were reared in tiered cages to the age of 6 to 8 weeks, was trialled and widely adopted. However, this system proved to be very labour intensive and costly to install, and was abandoned.

Battery brooders

Battery brooder

Of interest in reports of 1934, was the work of the Employment Promotion Council and the assistance provided by Parafield Poultry Station, in settling families on the land. During the year, ‘twelve families were settled at Echunga, one at Jupiter Creek, nineteen at Yundi, and four at Bridgewater’, all were supplied with a small flock of white leghorn pullets from Parafield.

One of those settlers from Bridgewater won the Egg Laying Competition conducted at Parafield just a few years later.

Mains power

In the year ending June 1935 electric power was installed throughout the area. When connected to Parafield Poultry Station the old Mammoth incubators were replaced with a modern electric machine of 8,600 eggs capacity, and electric battery brooders were installed. This resulted in greatly increased visitor numbers.

In the following years the Employment Promotion Council installed incubators at Parafield for the purpose of supplying the settlers with day old pullets. The combined capacity of those and the Station machines was approximately 45,000 eggs, and nearly 100,000 chickens were hatched during the breeding season from July to September. The eggs for the Council’s machine were brought from the various settlements, incubated, and after the day old chicks had been sexed, the pullets were returned to the settlers involved. During the season the combined machines hatched about 1000 chickens a day.

Aerial view, Parafield Poultry Station, 1940.

During the 1938/39 year Allan A McArdle was appointed as Farm Manager.

In March 1939 the first Egg Investigation Laboratory in Australia was established at Parafield Poultry Station. Research work into problems connected with egg defects and conditions, and general problems encountered in the marketing of eggs in shell and as pulp was carried out by a full time research scientist. This work included ‘the influence of diet on the bacterial flora of the egg; the ability of the shell to resist bacterial invasion; and the bacteriological examination of egg pulp’.

In July 1939 Mr Anderson represented the Commonwealth of Australia at a Poultry Conference held in the United States of America. Following that conference he proceeded to Great Britain to investigate the distribution and marketing of Australian eggs.

At that time, the British Government would buy as many eggs as Australia could supply, and during the season approximately 1.5 million dozen were exported from South Australia. The quality of the eggs arriving in Great Britain did not impress Mr Anderson, and on his return he made arrangements to conduct a special school in poultry husbandry at Parafield. He stated that ‘with the increasing demand for Australian eggs in Great Britain, the need for improved methods of production and marketing was never greater’. The school ran over a 3 day period during September 1940.

Eggs packed for export.

The work of remodelling old laying houses and building new and larger commercial type units continued during the 1940s. In 1945 a small experiment was conducted to test the “battery” system of housing layers. This ultimately became established universally as the “Laying Cage” or “Caged Layer” system of housing layers, and remained the method of choice by egg producers long after Parafield Poultry Station was closed.

Table meat

One of the many interests of the Farm Manager, Allan A McArdle, at this time was to improve the profitability of table meat production. Many day-old cockerels of all breeds were destroyed following sexing, and this was a waste which should be remedied. As part of the work which followed, a shipment of 500 crossbred table birds was sent from Parafield to the United Kingdom, through the Government Produce Department. Reports received from the U.K. indicated that this was regarded as the best consignment of table birds ever received from South Australia.

Mr Allan McArdle was appointed Senior Poultry Adviser and transferred to the Adelaide Office in 1950,’and Mr M D Jones was appointed Farm Manager.

Experiments were conducted with the ‘Infra-red lamp’ system of hot brooding for chickens with very encouraging results and lower capital costs, and this system persists today.

Infra-Red Brooder.

During the 1950s electric lights were installed in some laying sheds to determine the effects of increased hours of light on laying patterns, and growth rates, particularly during the autumn and winter period.

All sheds were operating on the ‘deep litter’ system with a resultant saving in labour.

An egg laying test on behalf of the National Utility Poultry Breeders Association was initiated for which fertile eggs supplied by the various breeders were incubated at Parafield and the pullets raised and tested for egg production over a 50 week period.

In the late 1950s attention was directed to poultry meat production on a much more intense scale, and operations at Parafield contributed to that development which came to be known as the “Broiler Industry”. The object was to produce a bird of 3 lbs. live weight at 12 weeks of age.

The egg laying tests continued, and the annual field days continued to attract large crowds.

Reports indicate that a record number of producers visited the centre during the year, and that approximately 40,000 chickens were hatched and 37,000 sold to commercial farmers.

Broiler chickens.

Housing design

Layer shed designs were constantly in mind and a style which was giving good results at the University of California and became known as the ‘Dryden shed’ was trialled. This gave excellent results and was widely adopted throughout the State. The basic principle of this design ensured that all droppings voided whilst the birds were on the perches accumulated outside the main floor area, and were isolated from all scratching litter to which the birds had access.

Dryden shed.

In 1959 the feeding arrangements at Parafield were completely changed. The morning wet mash with whole grain later in the day, as championed by Mr Laurie when the Station was opened in 1912, and which had prevailed for 47 years, was replaced with a dry mash, continuously available to the birds through self-feeders.

During the 1960s the single test competitions continued for pure bred stock, whilst the random sample test was broadened to include cross bred pullets.

A new strain of White Leghorns, founded on breeding stock from CSIRO Werribee, was developed and proved superior to the Parafield strain.

The performance of cross-bred layers was tested and these averaged over 30 eggs better per bird, during the test period, than the pure breeds.

Feeding trials continued with various blends of ‘high energy’ and ‘high fibre’ diets.

Egg yolk colour was shown to be a factor in consumer choice and various foodstuffs and chemicals were trialled in an effort to improve yolk colour.

New Hampshire cock.

New Hampshire hen.

In the field of genetics, Parafield was recognised throughout the Commonwealth and overseas, as a leader. Five strains of White Leghorns and three strains of Australorps had been developed and were constantly under test in various ways. Strains of New Hampshire and Light Sussex birds were also being developed. A White Leghorn strain, resulting from the interbreeding of CSIRO. Werribee and Parafield pure stock was dominant and in great demand from breeders. Similar breeding work continued with the Parafield strain of Australorps.

Light Sussex hen.

Light Sussex cock.

The mini line

The chance discovery of a dwarf bird in a flock of White Leghorns in 1968 created much attention. Detailed work by the geneticist, Dr Roger Polkinghorne, confirmed that the causative gene was recessive and sex linked, and strains of dwarf Australorps White Leghorns and Meat bird breeders were developed. Birds carrying the gene were distributed to commercial breeders and research organisations throughout Australia and, it is believed, overseas. However, evidence of continued breeding work or the existence of resultant progeny of commercial value has not been found.

Work also continued on a male ‘Broiler’ line of meat birds, however, by the 1970s the Broiler industry was dominated by large commercial enterprises which employed their own specialist staff. The hatching of meat strain chickens by those breeders more than doubled in the 5 year period from 1965 to 1970. National figures showed an increase from 44,000,000 in 1965/66 to 90,000,000 in 1969/70.

In 1967 Mr A G Lowe was appointed as Farm Manager.

Parafield mini lines.

Parafield standard and mini line White Leghorn cocks. Taken in 1972.

To assist in establishing the chicken meat industry, the annual field days were redesigned to highlight and encourage the consumption of poultry meat on a daily basis, rather than as an annual Christmas specialty. Large charcoal burning spits were erected and sizzling chicken halves, basted with various dressings, attracted visitors from near and far. The wine makers of the Barossa supported their fellow poultry farmers, and probably encouraged visitor numbers, by supplying supplementary wines for the occasions. These Field Days attracted large numbers of established and potential poultry farmers, with attendances of over 500 people each year.

Chickens being BBQ’d at a field day.

Major improvements

During the latter part of the 1960s, the prudent efforts of Ray B Fuge, Senior Poultry Adviser, resulted in large grants being made available for the construction of new buildings, the purchase of scientific equipment and new machinery, and the employment of highly qualified research officers and auxiliary staff. These grants were accessible because of various funds levied on the poultry industry. They included the research fund of the Council of Egg Marketing Authorities of Australia, and a fund established by The Chicken Meat Federation of Australia; both of which were subsidised dollar for dollar by the Commonwealth Government.

Grants from these funds resulted in the construction of new buildings and the purchase of equipment and machinery on a scale not previously possible.

A “Poultry Research Laboratory” was built and opened by the Minister of Agriculture, The Hon C R Story M.L.C. on the 16th November 1968.

An “Administration Building” was built and opened by the Premier of South Australia, The Hon Don Dunstan QC. MP. on the 11th November 1972.

By the mid 1970s these buildings were fully operational and provided more modern facilities for the research and experimental work which followed, and complimented the work then being done by R M Hughes on egg quality.

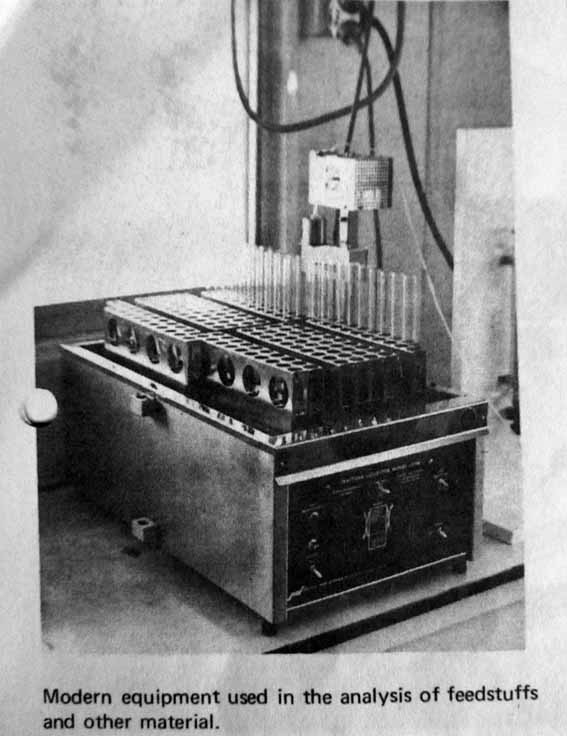

The Laboratory was well equipped for the analysis of foodstuffs as part of the nutritional research programme; for analytical studies on eggs and carcases; for more intense work in the field of genetics; and for studies on bird behaviour, with the use of closed circuit cameras and data loggers or computers.

The Administration Building housed the incubation and hatching unit which was constructed to hospital standards and equipped to facilitate the hygienic handling of fertile eggs and newly hatched chickens. It replaced older buildings, one of which was erected prior to the establishment of Parafield Poultry Station in 1911.

This building also provided offices, facilities for management and staff, and a conference room.

One is reminded of Mr Laurie’s first Annual Report, in which he expressed the hope that “Improvements being made at that time would include a Hall for lectures.”

His hopes were realised almost 60 years later.

Field Day crowd.

The modern Feed Shed housed a 30 cwt. vertical mixer, a 2cwt. paddle mixer and a roller mill for the preparation and mixing of foodstuffs. All rations used at the Centre were mixed on site from the basic ingredients which were bulk stored in six 250 bushel and five 4,000 bushel silos. These silos provided sufficient capacity to supply the Centre’s grain requirements for two years.

The Chicken Rearing facilities included battery brooders, weaner cages, rearing cages, deep litter sheds and free range, as required. Two rearing sheds each had the capacity for 5,000 pullets or 12,000 broiler chickens on deep litter.

Laying birds were housed on deep litter or in cages, with the intention that all layers would ultimately be caged.

Feed mixing.

A controlled environment shed equipped with cages, provided the ability to control the elements, such as light, temperature and humidity and thus ensure a more precise and constant environment for research work.

In 1973 a shed was built specifically for the purpose of breeding with the use of artificial insemination. It featured the benefits of a controlled environment and was designed to house birds for progeny testing and development as stud breeders.

Under new management

During 1975 major changes were made to the established pattern of management of the Centre when Mr Roger Polkinghorne, a scientist, was appointed as Officer in Charge and Farm Manager of Parafield Poultry Research Centre. However, very soon after his appointment, he took leave of absence in order to study for a Doctorate in America, and Mr Gordon Lowe resumed the position of Farm Manager. Dr Polkinghorne returned in the 1980s, but soon resigned from his position to pursue other interests. His last research project at Parafield was titled “The inheritance of some isozyme markers in the domestic fowl”. No conclusion to that study as it related to the Parafield Poultry Research Centre has been found.

Mr. Lowe retired as Manager at this time, and was replaced by Mr. D. B. Wellington, who would be the last Farm Manager of the Parafield Poultry Research Centre.

By the early 1980s the new facilities were being fully utilised by the geneticists and scientists who continued their research and experimental work in the fields of egg quality, bird behaviour, nutrition and breeding, whilst the supply of pure bred stock and day old chickens to commercial breeders continued.

At this time, Parafield was the only Government Research Centre in Australia engaged in commercial poultry breeding.

The Random Sample Testing and National Utility Poultry Breeders Association egg laying competitions continued to be of service to local and interstate poultry breeders.

Over 25,000 chickens were hatched annually and those not required for the planned research work found a ready market amongst the commercial breeders.

Research and experimental work continued, with egg quality factors, particularly in relation to the shells; nutrition, as it related to the various age and sex groups; bird behaviour, particularly within the caged environment; and genetics, being the major topics.

Dr A S Pell continued his research in the field of nutrition, with work directed at the nutrient density of the rations fed to the laying hen during higher temperature summer conditions. It was well recognised that food intake dropped at such times and that egg production was affected.

Dr Phil Glatz continued his work which was focussed mainly on bird behaviour, particularly in the caged environment. (Being rather old fashioned in that respect, my advice would have been, just take them out, put them on the ground, and give them a life). However that was not at all likely to happen and such research was vitally important. Dr Glatz was also working on stress factors, and their effects on the laying hen. These may have been due to husbandry practices such as beak trimming; excessive density by overcrowding in the layer cage or shed, or perhaps by disturbance caused by the farm hand or the system.

Mr R J (Bob) Hughes, who had worked very closely with the Egg Marketing Board for several years, continued his research. One of his aims was to define the combined effects of diet, temperature and atmospheric carbon dioxide on the acid based balance of the blood and its role in shell formation. He also continued his research on nutrition; with studies on the digestibility of various foodstuffs such as feather meal, poultry meal, field peas, safflower meal, barley and vetch, with particular emphasis on the use of barley as the main dietary component.

Incubating the eggs.

Abandoned

By the mid 1980s it was evident that the egg industry was following the pattern of the chicken meat industry. Large commercial enterprises with international connections had established breeding units in the eastern states and were monopolising the trade, whilst stud breeders were becoming obsolete. The breeding of pure-bred stock, on a commercial scale, for both egg and meat production, had ceased, and imported hybrid lines monopolised local chicken markets.

The Random Sample Laying Test, and the National Utility Poultry Breeders Association Egg Laying Competition, both of which had been conducted at the Parafield Centre for many years, and were highly valued by stud breeders and egg producers alike, closed.

The highly prized and long established pure strains of White Leghorns and Australorps, and the more recently developed lines of the New Hampshire and Light Sussex breeds, were abandoned; whilst the breeding and sale of purebred adult stock and day-old chickens, ceased.

One is reminded of a letter received by Mr D F Laurie in 1912, thanking him for a batch of fertile eggs from his prize winning strain of White Leghorns. The letter was written by Mr Prain, a Member of the Scottish Agricultural Commission, and Officer in Charge of the poultry industry in Scotland. However, Mr Prain did suggest that, although it was a little early to judge, the egg size seemed to be rather small. Mr Laurie probably noted that comment.

During the following years the breeding and incubation of eggs for the maintenance of farm stock and research purposes continued.

Bob Hughes continued his work, in collaboration with the South Australian Egg Board, which was mainly directed at egg quality, both of the shell and when broken out for cooking purposes. He also continued his work on nutrition with the aim of improving the nutritional value of the feed by the use of various protein and vitamin supplements, and the resultant effect on egg quality.

Dr Glatz continued his research on a range of husbandry practices, with his main object being the elimination of stress in the laying environment.

In the early 1990s, a review of South Australian egg marketing legislation resulted in the repeal of the Marketing of Eggs Act 1941 and of the Egg Industry Stabilisation Act 1973. The South Australian Egg Board was disbanded and the egg industry deregulated.

This brings to mind the work of C F Anderson, a former manager of Parafield Poultry Station, whose dedication to the marketing of only fresh infertile eggs, which was mentioned in this report for 1918, led to the Marketing of Eggs Act of 1941.

In 1992, the report which followed a major review of the Department of Agriculture in South Australia, was released. One of the conclusions from this review, was that the intensive livestock industries, such as poultry, offer a low level of opportunity, but a high degree of industry ability to develop those opportunities with little or no help from the Government. The Departmental response to that report was to proceed with the closure of the Poultry Research Centre at Parafield and to relocate, in a more modest way, at Roseworthy.

During the year the activities of the Research Centre staff were broadened by more intense collaboration with other research groups. Resultant initiatives included research on broiler nutrition in conjunction with the Commonwealth Scientific and Industrial Research Organisation; calcium physiology with the Institute of Medical and Veterinary Science; cage design with the Victorian Department of Food and Agriculture; and bird behaviour, with the Institute of Animal Production and Genetic Research, Scotland. Work also continued on the digestibility and nutritional value of various grains, including vetch, as a feed component, and on factors associated with egg shell quality.

Laying cages.

Closure

On Wednesday July 21st 1993 an article on the front page of the local newspapers revealed that “the doors would shut on Parafield Poultry Research Centre this Friday July 23rd”.

At about the same time an article written by Phil Glatz and Bob Hughes of the Parafield Poultry Research Centre stated that the South Australian National Egg and Chicken Meat Industries had received an enormous boost with the announcement of a new Pig and Poultry Production Institute to be built at the Roseworthy Campus of the University of Adelaide. It would offer unparalleled expertise to South Australia’s poultry industry and be responsible for the provision of technical support and services. It is to be a self funding institute in which all stakeholders play a major management role.

Some of those doors at Parafield Research Centre did shut on July 23rd, and members of the staff involved went their various private ways. However, the research and experimental work which was being done in conjunction with other research institutes, and on a local basis, continued.

Reports relating to the new facilities to be built at Roseworthy revealed that they would include:

- metabolimetry unit for broiler nutrition and welfare studies

- experimental broiler shed to house 5000 birds

- farm enterprise broiler sheds

- farm enterprise turkey shed

- multipurpose commercial broiler facility (20,000 broilers)

- controlled environment layer shed (2000 hens)

- four climate rooms for layer and broiler studies

- pullet rearing facility

- joint farm office centre and workshop shared with piggery

- nutrition and behaviour laboratory and offices.

Possession was to be given in 1995.

Despite the reduction in staff numbers, work continued at Parafield throughout 1994 and 1995. However the time available for research work was severely restricted. The officers devoted much of their time to monitoring the changed conditions in the Egg Industry caused by the closure of the South Australian Egg Board, and the effect which that had on the egg market.

Figures from the Australian Bureau of Statistics indicated that the price per dozen for large eggs in 1994 was 18c lower than in 1991 and 35c lower than in 1990.

However, the overall effect of that closure was for the better, and individual producers were able to prosper by their intuition.

Some of that intuition is still being tested by both the producer and the consumer, particularly in relation to the sale of what should be labelled “Free Range” produce.

Late in 1995, it was advised that the new Pig and Poultry Production facilities at Roseworthy were available for occupation. Research work at Parafield was reduced, and final plans for the closure were initiated.

During the transition period, work continued at both the Parafield and Roseworthy sites until Friday 8th March 1996, by which time the new facilities at Roseworthy were fully functional, and the Parafield site had been prepared for closure.

Mr. Ian Molloy had transferred to the Waite Institute to continue his work in the field of genetics, whilst Christine Adley, Phil Glatz and Bob Hughes would continue their work for the Poultry Industry, in new facilities at the Roseworthy Campus of the University of Adelaide.

Aerial view of Parafield 1968.

Relocation to Roseworthy

On Monday, 11th March, 1996, the keys of the Parafield Poultry Research Centre were handed to a representative of the government responsible for the sale of the property, by our Research Officer Bob Hughes.

Bob joined the Department as our first Poultry Research Officer in January, 1969. He completed his Masters degree in 1989, and was awarded the Australian Poultry Award (APA) for 2001, in recognition of his distinguished services to the Australian Poultry Industry. He gained a Doctorate in 2003, with his thesis being titled “Variation in the Digestion of Energy by Broiler Chickens”.

Eighty years ago, in his Annual Report for the year 1916/1917, our founder, Mr D F Laurie wrote, “It may now be claimed that practically all the problems of housing, breeding, rearing and feeding are solved”.

At about the same time a Special Reporter for “The Register” wrote, “The genuine experimentalist never marks time – his job is to be always at the front”

I leave it to the reader, if such there be, to judge; but obviously, at Parafield Poultry Station, the choice was made, to keep marching.

The Author

Errol Polden was appointed as a Poultry Adviser in 1950, and stationed at Riverton. He was the first poultry advisory officer to be appointed to a rural area. His brief was to lift the returns to the farming community which were derived from a participation in the various modes of poultry farming. He serviced all areas in and around Gawler and the Barossa Valley and extending to the east, west and north.

He was elected secretary of the South Australian branch of the World Poultry Science Association in the early 1960s, and served in that position until his retirement from the Department of Agriculture in 1972.