Improving fruit drying techniques and quality

The SA Department of Agriculture (and later SARDI) has had a long history of improving dried fruit quality, starting in 1908 with publishing of information about commercial fruit drying techniques (Bulletin No 44 “Fruit Drying in California). A major extension program to improve dipping, sulphuring and drying techniques for dried fruit producers was run from Berri Experimental Orchard in the late 1920s, including construction of a trial fruit dehydrating tunnel in 1924. Testing techniques for sulphur content of dried fruits were also introduced at this time.

Up until the 1970s, most dried stone fruit research was conducted at the CSIRO Division of Food Research (North Ryde, NSW). This focus changed with the establishment of a major program to improve the international competitiveness of South Australia’s dried stone fruit industry (run by the SA Department of Agriculture/SARDI). It commenced with the appointment of Adrian Dahlenburg as Dried Fruits Research Officer in 1972 and Jim Hill as Technical Officer Dried Fruits in 1973. The program continues today under the leadership of Michael Rettke (after retirement of Adrian Dahlenburg in 2010).

The SA dried fruit research and development program has focussed on dried apricots (the main dried fruit crop in South Australia) and has the following key elements:

- breeding apricots to improve drying ratios, yield and dried apricot quality,

- mechanising and reducing labour in apricot cutting drying systems,

- improving reliability and effectiveness of sulphur application systems,

- developing new dehydrator systems,

- improving shelf life in storage and retailing.

Apricot cutting machines

Economic studies showed hand cutting of apricots for drying was 20% of the cost of production. Cutting and fruit handling machines had the potential to prepare fruit for drying 7-10 times faster than hand cutting. Subsequently a long term project for development of apricot cutting and handling machinery was commenced in 1975 in conjunction with the SA Institute of Technology.

An initial survey of apricot cutting and handling machines identified the Williams machine as having the best cutting head. A project was initiated to refine this cutter, address fruit alignment problems, and improve tray loading. Over several seasons, fruit cutting and handling technology was improved, and adopted by many growers.

Early development work on cutting machines was also accompanied with research into fruit maturity and impacts on dried fruit yields. There was a continuous extension message to industry to harvest the most mature fruit possible to achieve the best drying ratios and dried fruit yields.

Research to understand the impact of heavy rains on the drying ratios and dried apricot fruit quality following these weather events was significant. Information developed from this work allowed producers to make better informed decisions about the financial impacts of harvesting and drying fruit during the first 5 days after a rain event.

From the late 1980s to 2005 there was a strong linkage between the apricot breeding program and the fruit quality program with all promising new selections being processed into dried fruit and evaluated for quality and storage life.

Improving sulphuring

The treatment of cut fruit with sulphur dioxide for preservation is a critical component of the fruit drying process. It can be difficult to manage legal and desirable sulphur dioxide levels to consistently produce high quality dried fruit that is internationally competitive.

New portable sulphur treatment boxes for dried fruit - Paringa 1972. Source: PIRSA file 103448

Initially growers built sulphuring enclosures with a range of rigid construction materials. With the advent of plastics, tent enclosures became very popular throughout the industry. Research into sulphuring techniques was undertaken for many years and achieved significant advances including:

- Mechanical sulphur burners to give consistent and reliable burning of the sulphur under all weather and wind conditions.

- Simple to use fully sealed sulphuring enclosures and dose rate data to permit the use of bottled liquid sulphur dioxide for fruit sulphuring.

- On-farm sulphur dioxide testing kits to measure sulphur dioxide content of fruit during the drying process. This enables consistent sulphur dioxide levels.

- New quick, simple sulphur dioxide test methods for dried fruit allows regular monitoring of fruit sulphur levels in storage to maximise shelf life.

Development of dehydrators

Through its history, the Australian dried apricot industry has almost exclusively used sun drying to achieve the traditional bright orange colour. In some circumstances, mechanical hot air dehydration was used to increase the drying speeds and reduce drying times in finishing fruit.

Through the 1970s to 1990s, the SA Department of Agriculture refined existing fruit dehydration systems, developing better LP gas heating and control systems to optimise drying. Extension information was produced to assist growers with designing and building more efficient dehydrators.

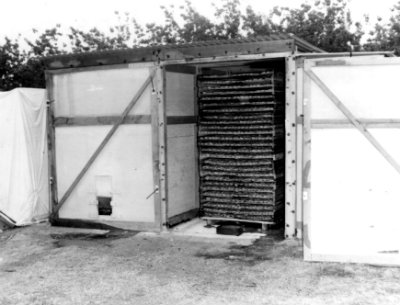

Developing LP gas fired dehydrators for drying fruit – Paringa 1972. Source: PIRSA file 103447

In the late 1990s, a small scale portable “heat pump” dehydrator was developed and successfully tested for fruit drying. The technology also attracted significant interest for other drying applications including pasta, straw brooms and paper mache products.

Quality retention

Quality retention during storage to achieve good colour and shelf life is vital. Prior to 1960, dried fruit quality was variable, and improved sulphur dioxide testing procedures and storage environments were needed.

Development of sulphur dioxide testing techniques enabled packing sheds to test batches of fruit for sulphur dioxide content, and allowed selective packing shed management for each line of fruit based on potential shelf life.

The program demonstrated the use of cold night air storage, a storage technique developed for the potato industry. This process uses insulated storage rooms while natural cold night air is drawn into the storage to maintain fruit at cool temperatures with minimal use of power.

Research also gave a better understanding of the shelf life and best handling and storage conditions for retail high moisture content (~ 30% moisture) “moist packs” of dried fruits.

Fresh stone fruit postharvest handling

The SA Department of Agriculture/SARDI was involved in significant postharvest research and extension projects for the fresh stone fruit industry from the late 1980s. This included:

- National improved cold chain handling project for stone fruit including supply chain temperature monitoring, internal breakdown studies, and numerous producer extension activities.

- “Ready to Eat” peach ripening and marketing program with Woolworths.

- Development of cherry maturity indices and optimal harvest maturity recommendations for key SA grown cultivars.

- Whole of supply chain handling procedures and monitoring protocols for the sea freight export of cherries.