Markets and marketing

Pre-canning and Refrigeration

Boiling down works became the norm for disposing of surplus sheep and cattle. As early as 1843 Pastoral Pioneers states “Mr FH Dutton is about to move into town a flock of 500 ewes with a view to boiling them down as the first wholesale experiment of colonial tallow making” By 1870 there was at least one other boiling down plant in Port Adelaide, and William Dean established a canning plant in association with the works but it lost money (various Government Statistical Registrars and Livestock Statistical publications, Yelland Leith, Pads tracks and waters, Govt. of South Australia, (2002)).

In 1870 (a Murray flood year) Mr McLean (Pastoral Pioneers vol 2, p167, various Government Statistical Registrars and Livestock Statistical publications), faced with no market for fat stock solved it by establishing a boiling down place at the Government Well on North West Bend. Other biographical sketches note pastoralists at Gawler and Robe both establishing boiling down works and hints that others intended doing similar. It needs to be noted that the prime aim was to dispose of sheep, but cattle were also dispatched in a similar manner. It seems amazing that so many became so wealthy with such limited markets for their product.

Photo No.: 108774 Title: Loading Steam Ship, Woolloomooloo with the first Shipment of export mutton from the South Australian Government Export Produce Depot, Ocean Steamers Wharf at Port Adelaide in October 1895. Date: 1895

In 1875 the State was exporting £1,833,519 worth of wool but the total of all miscellaneous goods was only £174,634 including tallow (25,670 cwt., value £38,511), preserved meats (562 tons value £28,241); leather, hides and skins (£20,549) (Statistical Handbook of the Australian Meat Industry plus various MLA publications). This demonstrates the lack of export markets for beef meat (although canning was having an impact from the early 1870s) and that numbers needed to be in balance with local population. In the early days all pastoral leases were held with the condition that whenever the land was required for agricultural purposes, the squatter must leave on receiving six months’ notice, the lessee being paid for substantial improvements made on his run.

Stock Agents and Saleyards

Selling of the surplus stock arriving overland in the 1840s led to the development of selling agents called “Stock Agents”. The first overlanded cattle were sold at the sites where they arrived, often in the Adelaide Hills or at “Bull’s stockyard on East Terrace which was a prominent landmark” A public slaughter yard (mainly for cattle) commenced operating in the Adelaide Parklands near Thebarton in 1841. (Maurovic Richard, The Meat Game, Wakefield Press, Kent Town, SA (2007)). Richard Maurovic in his book “The Meat Game” devotes Chapter Two to the development of the role of the agents with the key early companies including John Bull; Dean and Laughton; Elder, Smith and Co. and Dalgety and Goldsborough Mort. (Technology in Australia 1788–1988, Ch 2, Australian Academy of Technological Sciences and Engineering, Melbourne (1988), (Online 2000)). Since that time numerous companies have been formed and met their demise due to company takeovers, personal followings and economic declines. The agents provided financial assistance through stock mortgages for many cattlemen to get started and to restock following droughts and consequently built up an extremely loyal clientele.

Photo No.: 103756 Title: Northern store yearling cattle. Date: Mar 1970

The first cattle auctions were conducted by Dean and Laughton in the vicinity of the Glynde Hotel in 185622. The public slaughter house was built near Thebarton in 1841 and all cattle slaughtering within three miles of the city had to be done at this premises, in addition there was also a boiling down works nearby. A replacement slaughter house was built, in what is now Bonython Park, in 1880. Following this, in 1884, the Adelaide Corporation Yards cattle market was built just west of the current police barracks. The area became know as Newmarket hence the “Newmarket Hotel” on the West Terrace/North Terrace corner of Adelaide.

After much community debate it was agreed to build new selling and slaughtering facilities at Gepps Cross and the abattoirs and saleyards were opened in July 1913. Maurovic details the changes to legislation resulting in the formation of Metropolitan Abattoirs Act and various variations following this.(Technology in Australia 1788–1988, Ch 2, Australian Academy of Technological Sciences and Engineering, Melbourne (1988), (Online 2000)) All domestic meat was slaughtered at the works and delivered by the abattoirs to the butcher shops, while export produce was slaughtered at the Government Produce Department works at Port Adelaide.

A significant change occurred in 1959 when a new isolation saleyard was added at Gepps Cross to sell cattle from Central Australia. These yards were adjacent to the pleuro-pneumonia quarantine area. This later became known as the Southern Yards and in the early 1960s sales in the ring ceased due to cost and pen selling became the norm. Later a new isolation area was created to handle suspect cattle under the BTB eradication program, continuing until 1984 when they were again all open facilities. An innovation occurred in 1993 when liveweight selling commenced and cattlemen had the opportunity to sell their stock on a per head or per kilogram basis.

In 1986 the sheep and pig saleyard area north of the railway line was sold by the government but leased back to the South Australian Meat Corporation (SAMCOR). Sale of the Gepps Cross cattle saleyard and abattoir facilities, by the government in 1997, was a difficult time, which eventually resulted in new private saleyard facilities being established at Dublin.

Gepps Cross has traditionally been the main cattle saleyard in SA, using the sale ring and later with open yard selling. However the increase in cattle numbers in the South East plus regional abattoirs both in SA and the eastern States saw the development of significant regional saleyards at Naracoorte, Mt Gambier and Millicent.

Government Produce Department

The Produce Export Department was established in the 1890s to negotiate lower freight rates, quality certification and economies of larger scale marketing operations including frozen meat.(Pastoral Pioneers of South Australia Vol 1 & 2, Publishers Limited, Adelaide, (1925)) By 1896 it boosted the butter trade and started new exports including eggs, fresh fruit, honey, bees wax, almonds, and frozen meat. In 1895 it established the Port Adelaide Freezing Works and in 1907 an export slaughter works on the site.

Photograph captured in 1896 of the Department of Agriculture, Produce Export Branch buildings at Ocean Steamers Wharf, Port Adelaide. The building on the left is the freezing chambers and cold storage and on the right is the slaughterhouse. Date: 1896

In 1934, following an enquiry, the Metropolitan Export Abattoirs Board was established controlling all meat processing, with the result that all animals were slaughtered at Gepps Cross and the Port Adelaide works ceased. This resulted in significant expansion of slaughtering and freezing capacity at Gepps Cross. Prior to this all slaughtering was done individually or by teams working on individual animals. The new works incorporated moving chain slaughtering. For many years, the abattoirs coldstores were the largest in the southern hemisphere.(Technology in Australia 1788–1988,Ch 2, Australian Academy of Technological Sciences and Engineering, Melbourne (1988), (Online 2000))

Photo No.: 108795 Title: Export Lamb Competition arranged by the South Australian Branch of the Society of Breeders of British Sheep. They were shipped by the South Australian Government Produce Department to this butcher located in Portsmouth, England. Date: 1910

The Government Produce Department later had a range of other duties including purchasing meat for government institutions (such as goals and hospitals). During World War Two it exercised Commonwealth Government control over the marketing of meat and a range of other produce. Following the War it reverted to the role of supplier of produce to government institutions ceasing to exist in October 1975.

Marketing - Produce

After 1839 the cattle numbers quickly supplied the needs of the colony for food, tallow, breeding and draught purposes. However, other than hides and tallow, there was no outlet for the surplus as meat could not be stored or transported over long distances. In Britain, rapid population growth and cattle plague had drastically reduced the cattle herds in the second half of the nineteenth century, leaving a marketing opportunity. Initially canning was used and Australia was in the forefront of developing refrigerated shipping.

Photo No.: 108806 Title: The first direct overseas shipment of frozen lamb carcasses from Port Lincoln by the Steam Ship in 1930. Date: 15 Dec 1930

Technology in Australia (Technology in Australia 1788–1988, ch 2, Australian Academy of Technological Sciences and Engineering, Melbourne (1988), (Online 2000)) 1788–1988 published on line by the Australian Science and Technology Heritage Centre(https://www.austehc.unimelb.edu.au/tia/) provides an extensive national history of the technological development of meat processing for export including canning and freezing. In the 1780s Nicolas Appert, a Frenchman, began experiments that led to heat processing of food. Canned foods were known in Australia at least as early as 1815. By 1840 Australia had established a pastoral industry, but by 1843 multitudes of cattle and, especially sheep, were being boiled down for tallow. This crisis and the rapid introduction of the tallow industry which accompanied it have been described in KTH Farrer’s book (Farrer KTH, A Settlement Amply Supplied, University Press, Melbourne, (1980)) “A Settlement Amply Supplied“, Chapter 4. It spelt disaster for some but it catalysed the introduction, by Sizar Elliott, of the heat processing of foods. (In Adelaide in the 1840’s Bagot’s boiling-down works was established within view of the city slaughterhouse at Mile End).(Farrer KTH, A Settlement Amply Supplied, University Press, Melbourne, (1980)). When, therefore, in the wake of the boiling down frenzy, Elliott saw masses of cooked meat strewn on the fields as fertilizer he set himself the task of establishing meat processing in Sydney. All cans in those days were large by modern standards, 6 lb being the most common size. This led, of course, to serious over-cooking, which was the major criticism levelled at Australian canned meats when they were introduced to the general British market some twenty years later. Refinements of the techniques and processing methods resulted in companies developing across eastern Australia to meet the market. In the decade 1869–79 the Australian meat preserving industry exported some 65,000 tons of preserved meats to England, and 19,300 tons in 1871–2. This trade was stimulated by the demand for meat resulting from the shortage induced by the cattle plague in England and was aided by the Franco-Prussian War of 1870–1 and the virtual lack of competition from the Americas until late in the decade.

Heat processing was the first major innovation in food technology in the nineteenth century; the second was refrigeration and though others in other parts of the world had successfully lowered temperatures mechanically, the first mechanical ice making machine was put into operation in 1851 by James Harrison at Rocky Point on the banks of the Barwon River at Geelong in Victoria (Farrer KTH, A Settlement Amply Supplied, University Press, Melbourne, (1980)). It failed financially because he could not beat the vested interests who imported natural lake ice from North America. Harrison had begun with an ice making machine, but the thrust of Australian work on refrigeration from the 1860s onwards was towards the export of fresh carcase meat to England. That is, through the tropics, a problem which did not confront the North Americans, who relied on natural cold. The Americans and Canadians could ship meat to England without too much trouble, especially in winter, but the South Americans and Australians simply had to solve the problems of shipboard refrigeration. The meat and some experimental kegs of butter were loaded from chill rooms in Sydney and Melbourne and, freezing the consignment on board, the ship Strathleven left Melbourne on 6 December 1879 and arrived in London on 2 February 1880. Technical men travelled on the ship to oversee the trials and the voyage was well documented. The meat was in excellent condition on arrival and sold well. The trade developed slowly, inhibited by the lack of refrigerated ships. The first shipment of frozen meat was exported from Port Adelaide to Britain in 1895. Unsightly drip and freezer burn were two problems that faced the frozen shipping industry.

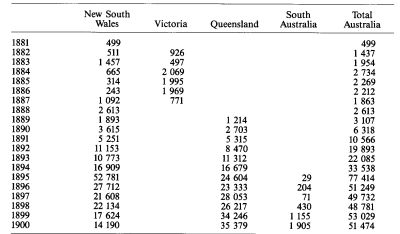

Export of Frozen Meat 1881-1900 (Tonnes). From: K. T. H. Farrer, A Settlement Amply Supplied, p. 250 amended.

In 1932 work at Cambridge showed that the storage life of chilled beef could be doubled by increasing the amount of carbon dioxide in the atmosphere of the refrigeration chamber. The chilled meat trade rose rapidly to 29,000 tons by 1937–8. Only a few shipments of chilled meat were made after the war. The cost of fitting up gas-tight chambers was high, and frozen meat was then preferred because of its very much better keeping quality.

Advances were made in the understanding and control of freezer-burn, in rapid chilling without excessive weight losses, and in the electrical stimulation of carcases during dressing to reduce toughness. During the Second World War a lot of meat was boned before shipment to save space. It was packed in cartons and frozen but the technique lapsed until 1957, when it was re-examined. It was revived with the help of plastic wrapping, a barrier to carbon dioxide and water vapour, vacuum packing, and the design by the refrigeration industry of more efficient blast freezers. High tonnages of beef and mutton are now exported in this manner.

Other advances at that time included the introduction, from abroad, of the mechanical removal of hides which increased through-put and reduced damage to both hides and carcases. In addition, exports to the United States led to demands for major improvements in buildings, equipment and handling to reduce Salmonella contamination.