Development of South Australia's citrus industry

South Australia’s Department of Agriculture/PIRSA/SARDI has played a key role in development of the state’s citrus industry since 1905. This article highlights major stages in development of South Australia’s citrus industry and key roles played by these agencies in its development.

For at least 70 years citrus has been one of the most significant horticultural crops in South Australia. In 2019 South Australia had 5,405 ha or, approximately 20% of Australia’s 28,000 ha of citrus plantings (Citrus Australia 2019). The South Australian citrus industry had a farm gate value of $136m in 2018–19 (PIRSA Primary Industries Scorecard 2018–19), and is a major export earner and employer in the Riverland region.

This article contains the following segments:

- Key South Australian Citrus Industry Development Highlights

- Development of South Australia’s Citrus Industry

- Citrus Industry Commodity Sectors

- Pest Management Programs

- Variety and Rootstock Improvement

- Storage and Packaging

- Irrigation and Drainage

- Tree Nutrition and Soil Management

- Crop Management and Regulation

- Citrus Export Market Development

- Citrus Industry Marketing and Industry Control Legislation

- Supporting Citrus Research and Industry Development

- References

- Acknowledgements

- Appendix 1 – Historic Department of Agriculture Citrus Publications

- Appendix 2 – Historic Citrus Growing Districts in South Australia – 1937

Download the Development of South Australia's Citrus Industry document ( ).

Key South Australian Citrus Industry Development Highlights

Following is a chronological list of the major factors, activities and events that have influenced the development of South Australia’s citrus industry.

1840–1860s

Citrus plantings gradually expand as irrigation properties are developed in the Torrens and Little Para River valleys to supply Adelaide’s expanding population.

1890s

Irrigation commences on the River Murray with development of new pumping technology, and citrus plantings commence.

1907

Assembly of a collection of citrus varieties and rootstocks commences at Blackwood Experimental Orchard.

1917–1929

Significant citrus industry expansion occurs after WW1 with the development of Soldier Settlement properties. Similar Soldier Settlement expansion also occurs after WW2.

1924–25

Citrus marketing cooperatives and packing sheds at Moorook, Mypolonga, Cadell, Barmera and Kingston on Murray are established with the assistance of loans from the Loans to Producers Board. This support was also provided to other packing sheds in subsequent years.

Image: Trade Commissioner promotion of South Australian citrus exports. Miss C. Dennis on steam ship Ballarat, 1934. PIRSA Photo ID 108803

1937

Export of fresh oranges to New Zealand gains momentum.

1945–1965

Post WW2 urban development around Adelaide displaces citrus orchards on the Adelaide Plains. Significant expansion of citrus plantings occurs along the River Murray.

1947

First fruit fly outbreaks in Adelaide. The decision to keep South Australia free of fruit fly would later enable international recognition of the Riverland as a “pest free area”, and facilitate access to export markets.

1950–1990

Rapid expansion of juice production to meet consumer demand results in the Valencia orange becoming the major citrus variety.

1965

Unstable domestic market conditions results in introduction of citrus marketing legislation via the Citrus Industry Organisation Act 1965.

1965

Adoption of biological control agents for managing red scale and other major pests commences.

Mid to late 1960s

SA Department of Agriculture’s post harvest research and extension program is expanded, led by Mr Barry Tugwell and Mr Adrian Dahlenburg. Innovations in equipment design for packing sheds and application of post harvest technologies enable development of new export markets.

Late 1960s

A program to move away from flood and overhead irrigation and improve irrigation technology commenced in the late 1960s and was led by Mr Keith Watson from 1971. It led the transition to drippers and under tree sprinklers in citrus orchards during the 1970s and 1980s. Improved irrigation reduced the impact of saline water and greatly enhanced tree health.

1969

A major survey to identify technology and information needs of citrus growers is conducted by Mr Peter Gallasch.

1970s

Citrus improvement program established to select, virus index and supply tested material for propagation to commercial nurseries. This included establishing a citrus foundation planting at Loxton Research Centre to provide high quality bud wood.

Expansion of exports to Singapore, Malaysia and other South East Asia countries.

Mid 1970s

Leaf analysis surveys (conducted by Dr Ben Robinson and district horticultural advisers) during the 1970s and 1980s validate plant test standards used in North America and develops standards for citrus in Australian. Further validation work by Mr Peter Gallasch in the 1980s improves translation of leaf analysis results into fertiliser application rates.

1975

Soil surveys of Riverland citrus nurseries and orchards (by Dr Graham Stirling) provides a clearer picture of nematode species present, levels of infestation in citrus soils, and effective management strategies.

1980s

Gradual adoption of superior or dwarfing rootstocks and planting of higher tree density orchards to improve productivity and reduce harvest costs.

1986

New quarantine protocols enable bud wood importation of many new varieties. The South Australian Citrus Improvement Committee plays a vital role in commercial evaluation of these new varieties and distribution of genetic material across the Riverland. Subsequent introduction of Plant Variety Rights legislation in 1994 added further momentum to the importation of new citrus varieties.

1986–87

Access to Japanese markets enabled by approval of cold sterilisation for fruit fly control. This allows further expansion of Asian exports.

1990–2005

Large increases in imports of low cost frozen orange juice concentrate from overseas, particularly Brazil, makes Australia production of Valencia oranges for juicing uneconomic.

1992

Export of fresh oranges to the USA commences. This proves to be a major and profitable market for Australian citrus growers up until the Global Financial Crisis in 2008. Escalation of the value of the $A during the GFC greatly reduces the competitiveness of Australian citrus in the US market.

1990s

Improvement of post harvest fungicide and oil treatments and introduction of in transit or shipboard cold sterilisation to ensure fruit fly freedom for export markets. This enables more economical transport by charter shipping to the USA.

Introduction of new varieties of mandarin, tangelo, lemon, orange and grapefruit create new choices for consumers. New types of easy peeling citrus become popular and continue to grow market share.

2001–2009

Millennial drought dramatically reduces water supplies in the River Murray resulting in many older Valencia orange orchards being abandoned and bulldozed.

2012

Repeal of citrus marketing legislation via the Citrus Industry (Winding up) Amendment Act 2012

2013 and beyond

Establishment of Free Trade Agreements with China, South Korea, Japan, and Indonesia reduces tariffs on Australian fruit entering these countries. This stimulates increased exports of fresh citrus and new citrus orchard investment.

Development of South Australia’s Citrus Industry

Citrus trees were introduced to South Australia by early settlers. By 1842, 6 varieties of orange were being grown in the state. Initially, South Australia’s citrus industry was located in close proximity to Adelaide in areas that are now Adelaide’s eastern, western and northern suburbs. Production was focussed on deep alluvial soils in close proximity to creeks and rivers, mainly along the Torrens and Little Para Rivers.

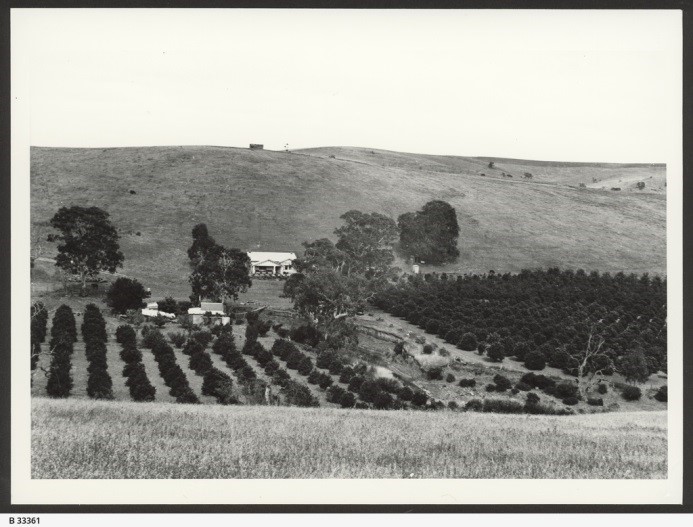

Image: A citrus plantation at Golden Grove in 1936. Source: State Library of South Australia image B33361.

Irrigation commenced along the River Murray in the late 1800s. By 1912 River Murray districts such as Renmark, Berri, and Waikerie were recognised for superior yields, and production of fruit with a thinner and smoother skin, and better eating and storage qualities. The light textured soils of these River Murray districts proved suitable for citrus. In Bulletin 107 (published in 1920), “The Orange in SA”, Mr George Quinn forecast that citrus production would move from coastal growing districts (near Adelaide) to River Murray production areas. This relocation to River Murray districts occurred slowly during the 1930s, but accelerated with rapid expansion of plantings after WW2.

Image: A young citrus grove at Waikerie in1917. Source: State Library of South Australia image PRG 1258/2/2604

In the post WW1 period between 1917 and 1929, SA’s citrus plantings increased by 40%. By 1929, South Australia had approximately 10% of Australia’s (21,978 ha) citrus plantings. South Australia’s plantings were made up of 2,032 ha of oranges, 191 ha of lemons, and 12 ha of other citrus fruits, with Navels making up two thirds of the state’s orange plantings. A national study (“Present Position and Future Prospects of the Citrus Industry in Australia”; Development Branch, Prime Minister’s Department; 1930) identified that by 1929, 51% of South Australia’s bearing citrus trees were planted in Murray Valley districts, with 46% in coastal districts including Salisbury. For further information of major production districts in the 1930s, see Appendix 2, Historic Citrus Growing Districts Near Adelaide.

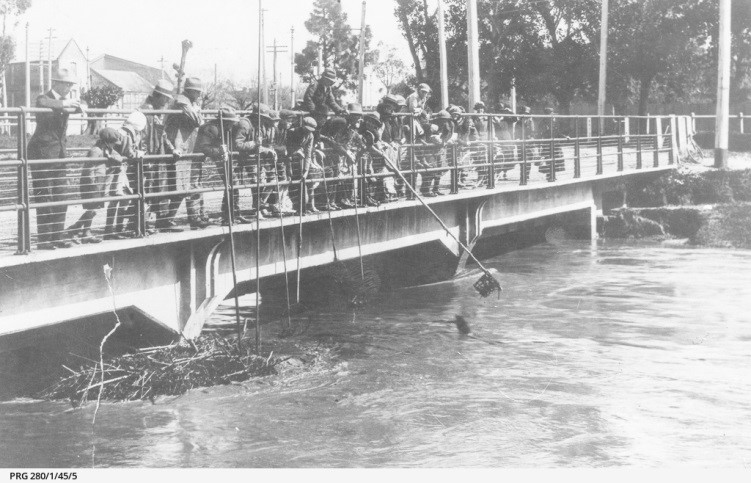

Image: Using poles and nets to catch oranges washed from eastern suburb orchards in a River Torrens flood – Hindmarsh Tramway Bridge. Observer Newspaper 29 Sept 1923, P 29. Source: State Library of South Australia image PRG 280/1/45/5.

In 1940, SA’s citrus industry had 465,000 trees (approx. 2,350 ha), and expanded steadily to 711,000 trees (approx. 3,600 ha) by 1954. Post WW2 War Service Land Settlement Schemes in River Murray production districts expanded citrus plantings by a further 1,081 ha, giving South Australia plantings of approximately 4,700 ha in 1956.

Post WW2, many of the citrus districts located close to Adelaide were developed for housing, and by the 1960s the majority of South Australia’s citrus was being produced in River Murray districts. By 1960–61, only 20% of Navel and 7% of Valencia oranges were being produced outside the River Murray districts.

Growing demand for citrus juice during the 1950s to 1990s saw Valencia oranges become the dominant variety. Competition from imported frozen juice concentrate placed downward pressure on juice fruit prices and a decline in Valencia plantings (see Citrus Juice section).

The River Murray Horticultural Crop Surveys were conducted every 2 years (from mid 1970s to mid 1980s) to monitor adoption of new and more efficient irrigation systems in horticultural industries. In 1981, the River Murray Horticultural Crop Survey identified the following citrus plantings:

Table 1: River Murray Horticultural Crop Survey 1981 Citrus Plantings (ha)

| Citrus | Citrus plantings (ha) |

|---|---|

| Navel oranges | 2,098 |

| Valencia oranges | 4,348 |

| Mandarins | 254 |

| Grapefruit | 333 |

| Lemons | 305 |

| Tangelo | 7 |

| Other citrus | 8 |

| Total Citrus | 7,353 |

In 2003–04, South Australia had approximately 7,500 ha of citrus plantings (Source: PIRSA; Regional Impact Assessment Statement – Review and Replacement of the Citrus Industry Act 1991).

Between 2001 and 2009, the Millennium Drought, the worst in 100 years, greatly reduced availability of irrigation water in the Murray Darling Basin. As a result, many older citrus plantings were abandoned and bulldozed, especially Valencia oranges being grown for juice manufacture. At this time, prices being paid for juicing oranges were similar to the cost of harvest. The development of La Nina weather conditions in 2010 gave above average rainfall across eastern Australia resulting in flooding and refilling of Murray Darling Basin water storages.

In 2003, South Australia’s citrus area was 7,327 ha, but had declined to 6,303 ha in 2008 (Citrus National Plantings Database 2011, Citrus Australia).During the height of the Millennium Drought, SA’s citrus production was virtually halved to 116,172t in 2007–08 and 119,515t in 2008–09 compared with 219,823 t in 2000–01 (ABS 7121.0 Agricultural Commodities, Australia).

In 2015–16, ABS citrus data (ABS 7121.0 Agricultural Commodities, 2015–16) highlighted the increasing importance of easy peeling varieties in South Australia’s citrus industry. Mandarin plantings had grown to 27% of SA’s citrus area (compared with 3.5% in 1981) while oranges declined to 67% (compared with 88% in 1981). Apart from approximately 40 ha of lemon plantings, all of South Australia’s commercial citrus was being grown in River Murray irrigation districts.

Australian Bureau of Statistics citrus area data is reported as tree numbers making it difficult to assess areas planted over time. Up until the 1970s, citrus orchards were traditionally planted at a tree density of approximately 80 trees/acre or 200 trees/ha. Subsequently with introduction of dwarfing rootstocks and high density orchards tree number /ha gradually increased. In recent years, there has been adoption of close planted hydroponic production systems in Australia that have tree densities as high as 1,000 trees/ha. Between 2003 and 2008, South Australia’s average tree density increased from 398 trees/ha to 436 trees/ha (Citrus National Plantings Database 2011, Citrus Australia).

Since 2014, increasing demand for Australian citrus fruit in China, Japan and other Asian markets has stimulated plantings of new orchards across Australia’s citrus districts. A census conducted by Citrus Australia in 2018 indicated that 13% of Australia’s citrus trees were non-bearing between 0–4 years of age.

Recent Citrus Australia data indicates that South Australia has approximately 5,405 ha of citrus plantings (2019).

Table 2: 2018–19 South Australia Citrus Production and Exports

| Citrus | Production (t) | % national production | Exports (t) |

|---|---|---|---|

| Grapefruit | 7,087 | 17% | 851 |

| Lemons & Limes | 8,682 | 18% | 1,251 |

| Mandarins | 31,383 | 23% | 16,956 |

| Oranges | 148,230 | 28% | 60,347 |

Source: 2018–19 Australian Horticulture Statistics Handbook, Hort Innovation.

Citrus Industry Commodity Sectors

In addition to fresh fruit for human consumption, Australia’s citrus industry produces a range of products including juice, beverages, peel and oil products.

Fresh Citrus

Fresh sweet orange fruits are by far the most popular citrus product with consumers. A range of Valencia and seedless Navel varieties provide fresh oranges almost year round. Cool storage is used to extend the marketing season. Today the Australian fresh citrus market is also supplemented with counter seasonal imports of navel oranges from overseas, mainly from the USA.

Easy peeling mandarin and tangelo varieties have grown in popularity with consumers because of their convenience, especially for lunch box meals.

Lemons and limes are used as condiments in a wide range of foods, and are popular for beverage flavouring.

Fresh grapefruit have long been popular as a breakfast food. From time to time, grapefruit have been popular in weight loss diets.

Citrus Juice Production

Before refrigeration and canning, orange, lemon and grapefruit juice was squeezed fresh from fruit by consumers as they required it.

In 1943, winemakers B. Seppelt & Son established a citrus juice canning operation at Nuriootpa to supply canned orange, lemon and grapefruit juice to allied armed forces during WW2. This plant was established to produce 1,000,000 30oz cans per year.

Canned citrus juices became popular with consumers after WW2. Canned juices provided a welcome market to utilise the large expansion of citrus production after WW2. The first Riverland cannery was established in 1948 by Berri Fruit Juices Coop Ltd. Berri Coop specialised in canning citrus juices, citrus oil, and produced numerous other fruit and vegetable juices and cordials. It had many structure and ownership changes during its period of operation, and closed in 2010.

The use of refrigerated display cabinets in delicatessens and supermarkets became popular in the 1960s. These enabled marketing of fresh squeezed and chilled citrus juices to consumers. Smaller fresh chilled orange juice packs became a popular take away beverage in competition with soft drinks.

Several local companies (such as Nippy’s and Crusta) established processing plants to manufacture and distribute fresh chilled orange juice products to supermarkets, delicatessens, hotels and other retail outlets. Mr Barry Tugwell and the Post Harvest Team assisted fresh juice processors with information on preservatives and safe handling procedures to ensure the best shelf life and quality for un-pasteurised juice products. Following food safety concerns, pasteurising systems were later developed for fresh juice products. Many of these fresh juice companies continue to manufacture and distribute products today.

Valencia is the main orange variety used for manufacture of orange juice. Juice produced from Navel varieties develops bitterness mainly due to the presence of Limonin and other flavour compounds. The Australian citrus industry was an early adopter of debittering processes, establishing one of the first commercial treatment plants using cellulose acetate beads in the late 1970s (Source: 1990 Citrus Engineering Conference, Lakeland, Florida, USA). Developing techniques to reduce bittering in citrus juice continues to be a major international research topic.

Juice bars have become popular in recent years. These use a wide range of fresh fruits and vegetables to produce on the spot freshly squeezed juice products for customers.

Development of Frozen Juice Concentrate Enables World Trade in Juice

Much of the technology for production of frozen orange juice concentrate was developed in the USA during WW2 with a view to supplying troops with a vitamin C source. The process for manufacture of canned frozen concentrate orange juice continued after WW2 and was patented by the Florida Citrus Commission in 1948. Frozen canned concentrate orange juice became a very popular product in the USA in the 1950s, one of the major consumer products being Minute Maid 6 fl oz cans. Florida had 3 frozen concentrate plants operating by 1948, but this quickly expanded to 10 plants in 1949.

Frozen concentrate technology revolutionised longer term storage, and transportation of bulk quantities of citrus juice around the world. This technology has allowed countries such as Brazil to become major world suppliers of frozen concentrate citrus juice products. Large areas of rainfall grown citrus, low labour and overhead costs have given Brazil a major competitive advantage in world juice markets.

Orange Juice Consumer Confusion

With widespread adoption of household refrigerators during the 1950s,100% fresh squeezed orange juice manufactured from Australian grown oranges became a popular product.

During the 1970s and 1980s,importation of frozen orange juice concentrate, mainly from Brazil and Florida, expanded rapidly. Reconstituted frozen orange juice was used in the manufacture of long life fruit juice drinks. These fruit juice drinks contained varying levels of juice, were cheaper to produce, and were pasteurised giving them long storage life at ambient temperatures.

Long life fruit juice drinks gained popularity with consumers because of their cheap price and storage convenience. Despite their lower juice content, long life fruit juice drinks replaced a significant quantity of the100% fresh chilled orange juice.

This change in juice consumption patterns along with frozen concentrate imports dramatically reduced demand for Australian grown juicing oranges. Australian citrus growers were forced to refocus back onto fresh citrus fruit production.

Decline of South Australia’s Citrus Juice Industry

In 1981, more than two thirds of orange plantings were Valencia, primarily for juice production. During the period 1987 to 1992, 56% of Australia’s citrus was being directed to processing, mainly for juice manufacture.

In 1990, prices for processing citrus fell from $180/t (August) to $85/t (October), driven by larger juice crops in Florida and Brazil. The price for processing oranges being paid to Australian growers had become volatile, being driven by fluctuations in world production of frozen concentrate juice. This triggered a review of the competitiveness of Brazil’s citrus industry, with key factors being lower costs of fruit production, cheaper labour costs, exchange rates, and the influence of tariff and sales tax levels.

Tariffs on imports of frozen concentrate and sales tax were applied to beverages with more than 5% content of imported concentrate, influencing prices being paid for processing citrus within Australia. These protection measures were subsequently removed over the years.

A long period of poor prices and the ageing of many Valencia orchards resulted in a gradual decline in production of juice fruit. Growers began moving to production of more navel oranges and “easy peeling” citrus varieties for the fresh fruit market and export opportunities.

In 2003 to 2005 a major economic study undertaken by PIRSA identified that oranges being grown for juice production were very unprofitable. In many circumstances, juice fruit prices barely covered the cost of harvesting. This study reinforced the need to switch to fresh fruit production. Subsequently, many older Valencia orchards were bulldozed or abandoned during the Millennium Drought between 2001 and 2009.

Per capita consumption of orange juice has also been declining for several years due to competition from other beverages such as iced tea and sports drinks. Consumer preferences are also moving to beverages with lower sugar content.

Citrus Peel Products

Glace citrus peel is produced by a process of steaming, soaking in sugar syrup, then drying. Citrus peel is used as an ingredient in a wide range of cakes and baked products.

Citrus oil is also extracted from peel and used as a fragrance in a wide range of products including air fresheners, cosmetics and skin conditioning agents.

Waste peel is also used in stock foods.

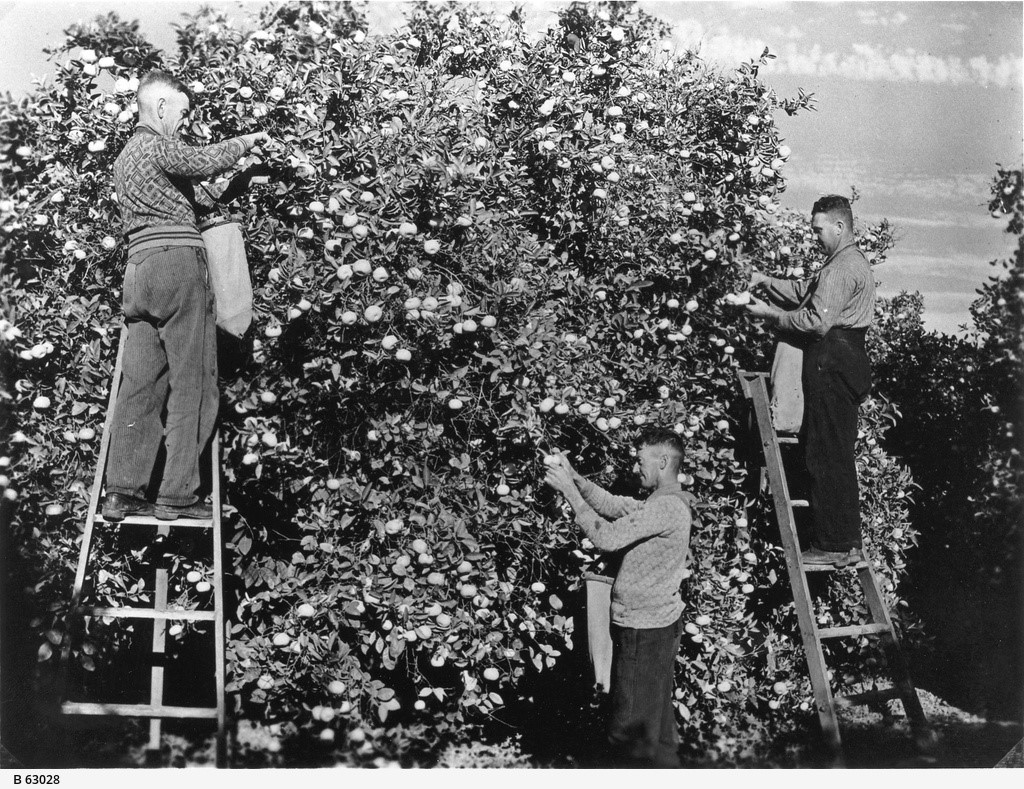

Image: Picking oranges at Renmark 1923. Source: State Library of SA Image B63028.

Other Processed Products

Several native citrus species are wild harvested or grown in commercial orchards(finger limes and summer limes are the most popular) for beverages, preserves, marmalades, chutneys, sauces, syrups, garnishes and confectioneries.

Pest Management Programs

Citrus groves are subject to a range of foliage and soil borne pests, including scale, aphids, snails, nematodes, viruses and other minor insects. Some of these pests and diseases can significantly reduce productivity and quality, while some have minimal impact but are of importance from an export market access perspective (eg Fuller’s rose weevil and snails).

Red Scale

Red Scale (Aonidiella aurantii) has been a major insect pest of citrus trees since establishment of the South Australian citrus industry. Red Scale reduces tree health, vigour and yields, and sooty mould associated with the scale impacts on fruit quality. The history of the control of red scale traverses a range of chemical treatments and ultimately led to the use of integrated pest management techniques. Equipment used for control of pests has also changed dramatically over the past 100 years.

In 1896, hydrocyanic acid gas fumigation of trees to kill red scale was demonstrated to citrus growers. This involved covering the tree with a gas proof tent and releasing cyanide gas inside the tent. By 1907 many citrus growers were using this technique, mainly via contractors. It was effective, but reinfestation from neighbouring trees that had not been treated was a major problem, especially in growing areas to the east of Adelaide where home gardens were in close proximity to commercial orchards. In 1912, 11,300 trees were fumigated in the Salisbury district.

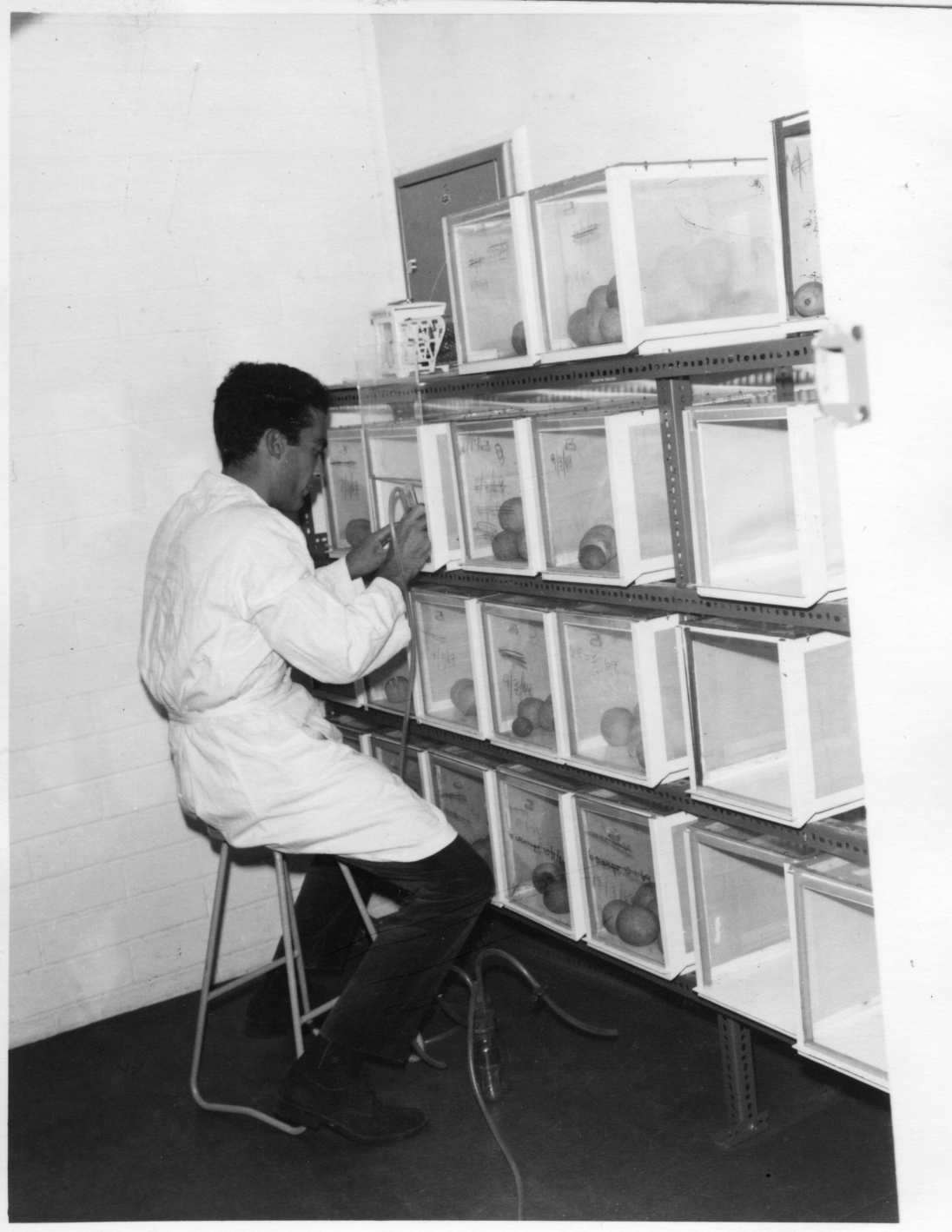

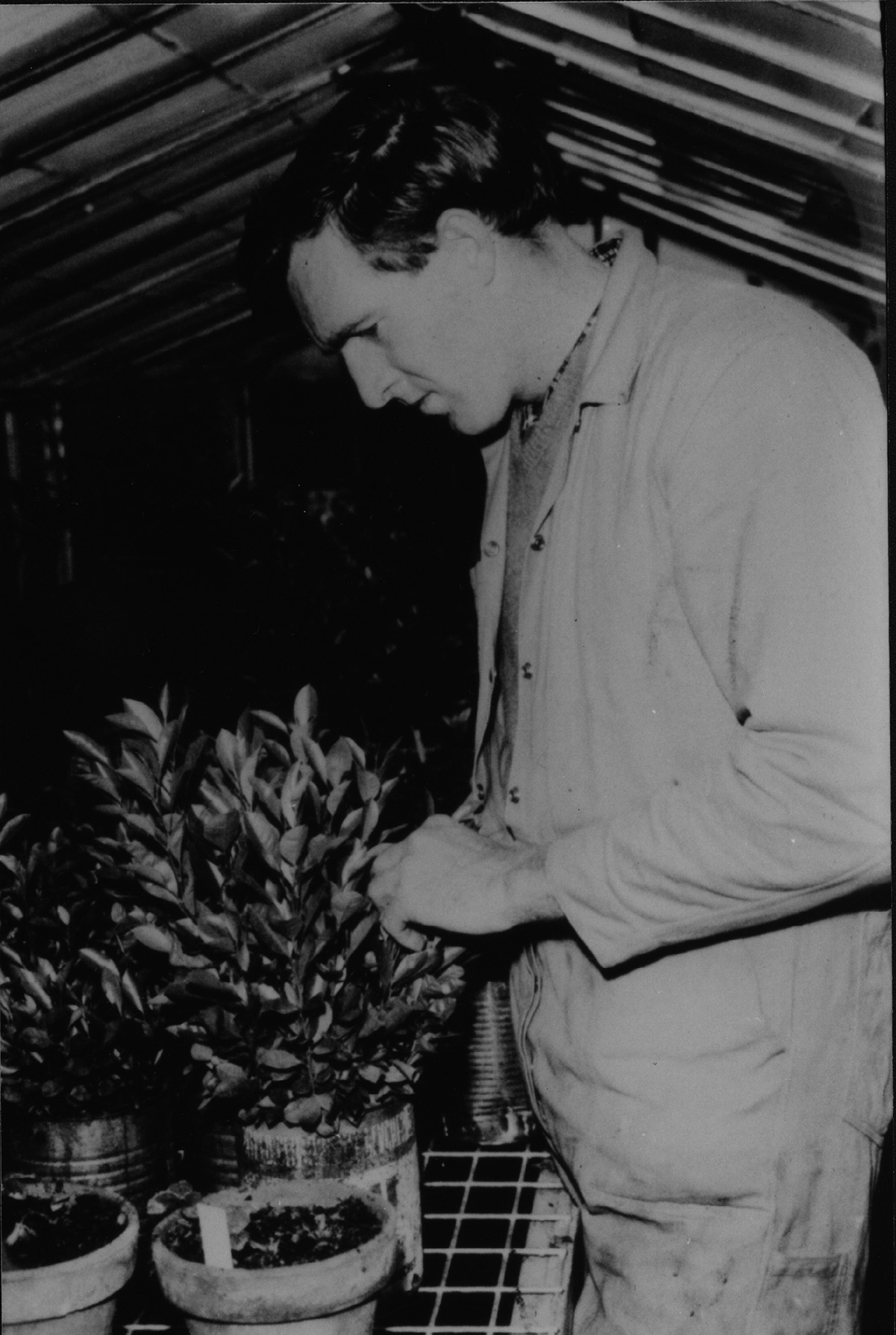

Image: Rearing parasites for citrus pests. Loxton Research Centre, May 1965. PIRSA Photo ID 104340.

Compulsory treatment was subsequently introduced requiring growers to use specialist fumigation contractors. Nursery trees being moved from Adelaide nurseries to River Murray districts were compulsorily fumigated. A red scale outbreak at Waikerie was secured with fumigation in 1932. Further red scale outbreaks at Mypolonga in 1934, and Berri and Renmark in 1936 saw expansion of tree fumigation to those districts. Fumigation of citrus trees for red scale control continued until the 1940s.

Early experiments with kerosene emulsion washes commenced in 1902 but were unsuccessful. Red oil sprays were also being evaluated in 1913 with limited success. Subsequently white oil sprays were developed to successfully control red scale.

Introduction of organophosphate insecticides from the 1950s initially provided good control, but created greater problems by killing most beneficial and predatory insects in orchards, forcing discontinuation of their use.

Red Scale was such a significant pest that the citrus industry had a Red Scale committee providing guidance for research and extension programs in 1958–59.

In the 1960s, entomologist Mr Noel Richardson commenced a major program at Loxton Research Centre to develop improved red scale control measures. This involved evaluation of a wide range of insecticides, spraying oils, and different spray application techniques, including aerial application with helicopters.

Image: Spraying citrus from a platform on a horse drawn spray unit – 1940. Source: PIRSA image 103486.

With support from Mr Malcolm Campbell, this led to evaluation of parasitic insects and building of a mass insect rearing facility at Loxton. The use of the parasite Aphytis malinus, in conjunction with reduced chemical applications proved to be highly effective for control of red scale in citrus.

In 1971, a privately owned commercial parasite rearing and distribution business, Biological Services, was established on Loxton Research Centre. During 1973 and 1974 a series of very successful training courses about the role of predators and parasites for red scale management were delivered to citrus orchardists across all major production districts. By 1976, an estimated 60% of citrus orchards were using parasites for red scale control.

Biological Services has been under the ownership and management of Mr James Altmann since 1987, and has gradually increased the range of biological control products and crops on which it was providing services. In 2014, Biological Services joined forces with Manchil IPM Services, a WA based biocontrol provider. Biological Services markets 16 different biological control organisms to a wide range of horticultural industries across Australia through a large team of production and field staff (Source: biologicalservices.com.au).

Image: Oscillating boom sprayer used for high volume citrus spraying – May 1963. Source: PIRSA image 103484.

Nematodes

Nematodes are a soil borne pest that dramatically reduces tree root performance, tree growth and yield. They are easily transmitted on the roots of nursery trees.

During 1975–76, a large number of citrus nurseries and orchards (along with other tree crops) were surveyed and sampled by Dr Graham Stirling to assess the significance of nematode populations on the citrus industry. This provided a clearer picture of nematode species present and the levels of infestation in citrus soils, and enabled delivery of more effective management strategies for nurserymen and growers.

In the longer term, introduction of nematode resistant root stocks became the main technique for overcoming nematodes in citrus orchards.

Fruit Fly

Fruit fly is a major pest of fruit crops in many countries. Following the first outbreak of fruit fly in Adelaide in 1947, the SA Department of Agriculture adopted a strategy of maintaining area freedom. Area freedom greatly reduced production costs for orchardists, and is critical for ease of market access into many countries.

Primary Industries and Regions SA currently protects South Australia’s horticulture industries through delivery of a major fruit fly strategy comprising:

- Controlling fruit and vegetable movements.

- Overseeing interstate movement of produce in accordance with each state’s entry requirements.

- Monitoring and trapping for fruit fly statewide.

- Working with the public to identify and report suspected maggots in fruit.

- Investing in research and technology.

- Eradicating fruit fly outbreaks.

Other Pests

There are a number of minor pests like snails, curculio beetle and Fuller’s rose weevil, which are often a biosecurity concern in exported fruit. Preventative measures like skirting trees, orchard floor management techniques, and occasionally under tree spraying are used to minimise risks of these pests contaminating export consignments.

Variety and Rootstock Improvement

Early Variety and Rootstock Collections

By 1919, the Department of Agriculture had assembled a collection of approximately 100 varieties of citrus (orange, lemon, lime, pomelo, mandarin, Seville, citron, kumquat, shaddock) at the Hackney Road orchard in the north east corner of the city of Adelaide Citrus trifoliata rootstocks were also planted at Hackney Road in 1923–24. This collection was moved to the Fullarton orchard in 1930 with the closing of the Hackney Road orchard.

By 1928 a collection of 112 citrus varieties had also been assembled at Blackwood Experimental Orchard. These variety collections were used to supply commercial citrus nurserymen with budwood.

Rootstock trials commenced at Berri Experimental Orchard in 1919.

In 1931–32, a rootstock by variety trial was established at Fullarton Nursery. It comprised 6 stocks; sweet orange, rough lemon, Seville/sour orange, trifoliata, Poor man orange, grape fruit/pomelo combined with the varieties Washington navel, late Valencia, Marsh seedling grapefruit, Lisbon lemon, Dancy mandarin and tangerine.

Citrus Nurserymen

During the early 1900s when SA’s citrus industry was mainly located in areas around Adelaide, nursery propagation of trees was concentrated in this region.

Propagation of citrus trees for post WW1 and WW2 War Service Land Settlement Schemes was done partly on Department of Agriculture research centres and also contracted to commercial citrus nurserymen.

Post WW2, rapid expansion of citrus plantings in River Murray irrigation districts resulted in growth of commercial nurseries in this region. Commercial citrus nurserymen have played an expanding role supplying orchardists with a constantly changing array of varieties and rootstocks for different soil, climate, market and pest conditions.

Mr Ian Tolley (Tolley’s Nurseries, Renmark) has been a significant leader in the citrus nursery industry pioneering new propagation techniques, travelling extensively overseas to obtain technical information, and assisting growers to select the best variety and rootstock combinations for their production sites.

Mr Tolley has also been a prolific author publishing text books about citrus production (“Commonsense Citrus – Hands on guide to propagation and planting”, Ihabi Publications, 2017) and encouraging home production of citrus through gardening publications, radio and TV programs.

Virus Indexing

Virus indexing of planting material commenced in 1962 by Mr Jack Botham following a visit to South Australia by Prof L C Weathers from the University of Riverside, California.

Virus indexing was expanded in the 1970s with introduction of Nucellar seed lines by Dr Rip van Velsen. During the 1970s, the citrus improvement program was established to select, introduce virus indexing (particularly for Xyloporosis,Exocortis, Psorosis and Tristeza viruses) and supply virus tested material for propagation by commercial nurseries. This included establishing a citrus foundation planting at Loxton Research Centre to provide high quality budwood for the main commercial citrus varieties, and seed from source trees for the main rootstock varieties. (Source: Loxton Research Centre Report No 1, December 1976, P 21).

Image: Dr Rip van Velsen virus indexing citrus nursery stock at Northfield Horticulture Pathology glasshouse, Northfield Research Centre – 1970. Source: PIRSA image 106362.

Variety and Rootstock Trials

Different nurseries were supplying various clones of Valencia. A Valencia clonal comparison trial was established at Loxton Research Centre in 1989 to evaluate the performance of numerous selections from NSW, Victoria and South Australia. Evaluation over 12 years revealed differences of up to 60% between the best and poorest selections. As a result, astute citrus growers began specifying the precise clone they wanted from their nurseryman.

During the late 1970s a wide range of new rootstock types were becoming available. Areas where citrus orchards were to be replanted posed special problems. Replant soils normally contained various nematodes and pathogens, and over time had been modified by irrigation and compaction. Mr Peter Gallasch (Senior Research Scientist – Citrus) established a series of replicated rootstock trials across the Riverland to assess the benefits of various old and newly imported rootstocks. This trial was a major undertaking, commencing with propagating of trial trees at Loxton Research Centre under the supervision of Mr Tony Bass. The planting, establishment and care of trial sites required, harvest and assessment followed by data analysis. Many of these trial blocks operated for over 12 years.

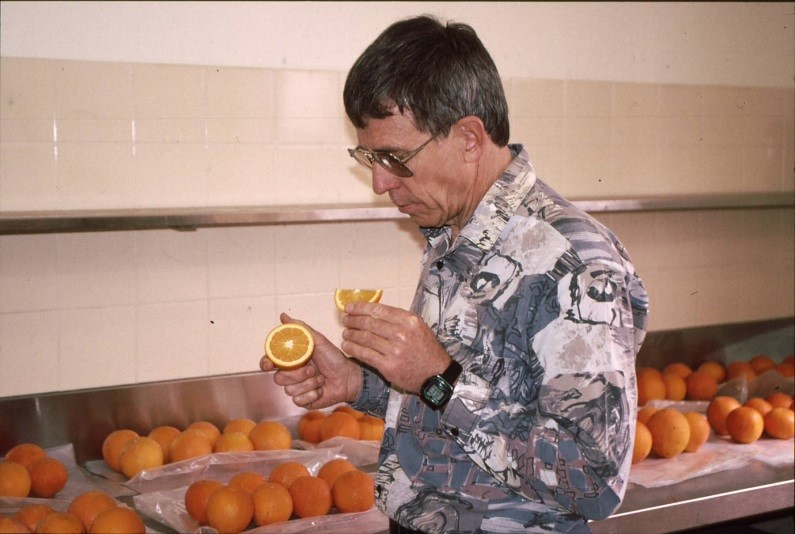

Image: Mr Peter Gallasch assessing fruit for palatability. Clonal comparison trials, 1994. Loxton Research Centre. Source: PIRSA Image.

Many new rootstocks were assessed in combination with new citrus varieties and types such as Murcotts, Ortaniques, new and old mandarin varieties, and red fleshed grapefruit. The tangor Ortanique was imported from the West Indies and has proved of interest in the late maturing mandarin marketing slot. Introduction of the Daisy mandarin from California was also particularly successful.

Federal legislation was changed in 1986 establishing protocols for the importation of budwood under strict quarantine procedures. This enabled importation of many new varieties, some initial examples being Oroblanco (a lower acid white flesh grapefruit variety), four red fleshed grapefruit varieties from Spain, Navelina and Newhall (early maturing navel oranges), and a range of early and late maturing lemon varieties. Assessment trials for these new varieties conducted in South Australia were linked to a network of replicated trial sites across Australia.

The South Australian Citrus Improvement Committee (for many years under the chairmanship of Mr Mike Arnold from Waikerie) played a vital role in commercial evaluation of new varieties across the Riverland and distribution of genetic material.

Introduction of the Plant Breeders Rights Act 1994 provided overseas breeders with a mechanism for collection of royalties for new improved varieties. Passing of this national legislation enabled a further range of new citrus varieties to be marketed in Australia.

Comparison trials to evaluate late maturing and late hanging navel oranges were established at Loxton Research Centre and on grower’s properties in 1988–89. This was to assess a number of overseas varieties (some with very high prices for bud wood) that were claimed to be superior to the Lanes Late variety. The best selections of late maturing navels could retain fruit on trees until late February and take advantage of high value markets. These comparison trials attracted visitors from California, Spain, Chile and other countries to see results first hand.

In the late 1990s, assessment of lemon production near Mt Gambier identified that summer maturing lemons could be successfully grown in the South East. However, this has not resulted in significant expansion of lemon plantings in this region.

Information about the performance and potential values of various varieties was published in Fact Sheets. These included a summary of grower friendly information on each commonly used root stock.

In 2017, a major review of citrus rootstocks was completed by SARDI (Mr Mark Skewes). The information gathered in this process was published in two documents available from the SARDI website:

- Citrus Rootstock Technical Guide – Mature Tree Assessments ( ) by M Skewes

- Longevity and Sustained Performance of Rootstocks in Lower Murray Horticulture: Viticulture and Citrus ( ) by T Pitt, M Skewes, J Tan and J Cox.

Salt Tolerant Rootstocks

Soil and water salinity emerged as a major problem in the 1960s and 1970s for Sunraysia and Riverland regions. After years of breeding, the Indio Field Station in California had produced a number of promising salt tolerant rootstocks. The best of these were imported into Australia by Mr Peter Gallasch for evaluation. Initially these rootstocks were grown in pots and evaluated in the nursery using high salinity irrigation water (3,500 EC). This reduced the number of rootstock candidates to 17.

The best performing stocks were propagated, top worked with a navel variety, and planted into a replicated experiment at Loxton Research Centre. To build up soil salinity levels, the trial was irrigated with 2,500 EC water except for the last 20 minutes of each irrigation cycle (normal irrigation water was applied at the end of each irrigation to prevent excessive leaf burn).

From this initial trial, a selection of the most salt tolerant rootstocks were propagated and planted in a further trial at Solora South near Loxton. After 15 years of research, this project was terminated.

Salinity problems were ultimately solved through improvements in irrigation practices, the construction of salt interception schemes, and better control of River Murray salinity levels.

Storage and Packaging

Post WW1 saw development of specialty citrus packing sheds in the Riverland. By 1935–36, 17 citrus packing sheds had been established at Berri, 3 at Renmark, and 1 at Barmera.

Rapid expansion of the citrus industry in the 1950s and 1960s, along with an increasing array of new post harvest technology resulted in greater coordination of citrus handling research between states. Post harvest research between the Sunraysia and Riverland districts was enhanced through the 1980s and 1990s with formalised meetings between NSW, Victoria and SA Agriculture Departments along with the CSIRO.

Commencing in the mid 1960s,the SA Department of Agriculture’s post harvest research and extension team was established, and led by Mr Barry Tugwell for more than 30 years. His unique ability to effectively communicate and work with industry personnel at all levels, along with a practical and applied approach to solving problems and applying new technologies, enhanced adoption of post harvest technology by industry. His innovations in equipment design for packing sheds, and application of post harvest technologies were significant in advancing the competitiveness of SA’s citrus industry and gaining access to new markets.

An array of other Department of Agriculture/SARDI post harvest personnel have supported the citrus packing industry including Messrs Adrian Dahlenburg, Kevin Gillespie, Jim Hill, Lindsay Jarrett, Peter Taverner, and Michael Rettke.

Image: Citrus packing – January 1965. Source: PIRSA image 103517.

Better mould control

By 1961–62, all large packing sheds had installed fruit washing and waxing equipment, necessitating evaluation of waxes, waxing techniques, and research programs for materials to minimise oleocellosis, anthracnose, stem and rind breakdown.

Mr Barry Tugwell developed a reliable fruit inoculation technique for testing and evaluating the efficacy of fungicides and fruit handling protocols. These inoculation techniques ensured reliable assessment of fungicide treatments, enabling research to reliably establish standards for the use of early industry fungicides like TBZR and later BenlateR.

Design of continuous on line fungicide application equipment for packing sheds ensured effective fruit coverage and fungus control.

Cool storage – evaluation of modified atmosphere storage

An individual fruit wrapping technique using ventilated plastic wraps was researched and developed for extending fruit storage life for navels and red fleshed grapefruit. This technique was used by Waikerie Cooperative for a number of years for grapefruit storage, enabling them to extend their marketing period and capture improved prices.

De-greening techniques

A method and equipment for de-greening lemons and early season navel oranges was developed using plastic tents, air circulation fans, and a simple bubbler device to trickle ethylene gas into the storage tent. This concept was then adopted by most packing sheds.

Improved Maturity Standards

Research at Loxton showed a high correlation between Total Soluble Solids (TSS) of fruit and excellent flavour. A tristate initiative by South Australia, Victoria and New South Wales attempted to convince packers to provide a financial incentive to growers delivering fruit with a high TSS. Market research showed customers were willing to pay more for fruit with a high flavour rating. Information was also provided to growers about management practices that would produce better quality fruit. Some packing sheds did adopt the practice and received higher prices by careful marketing and labelling of the superior fruit.

Citrus Australia now promotes standardised quality testing procedures for growers, packers, retailers and marketers via its Australian Citrus Quality Standards publication.

Changing packages

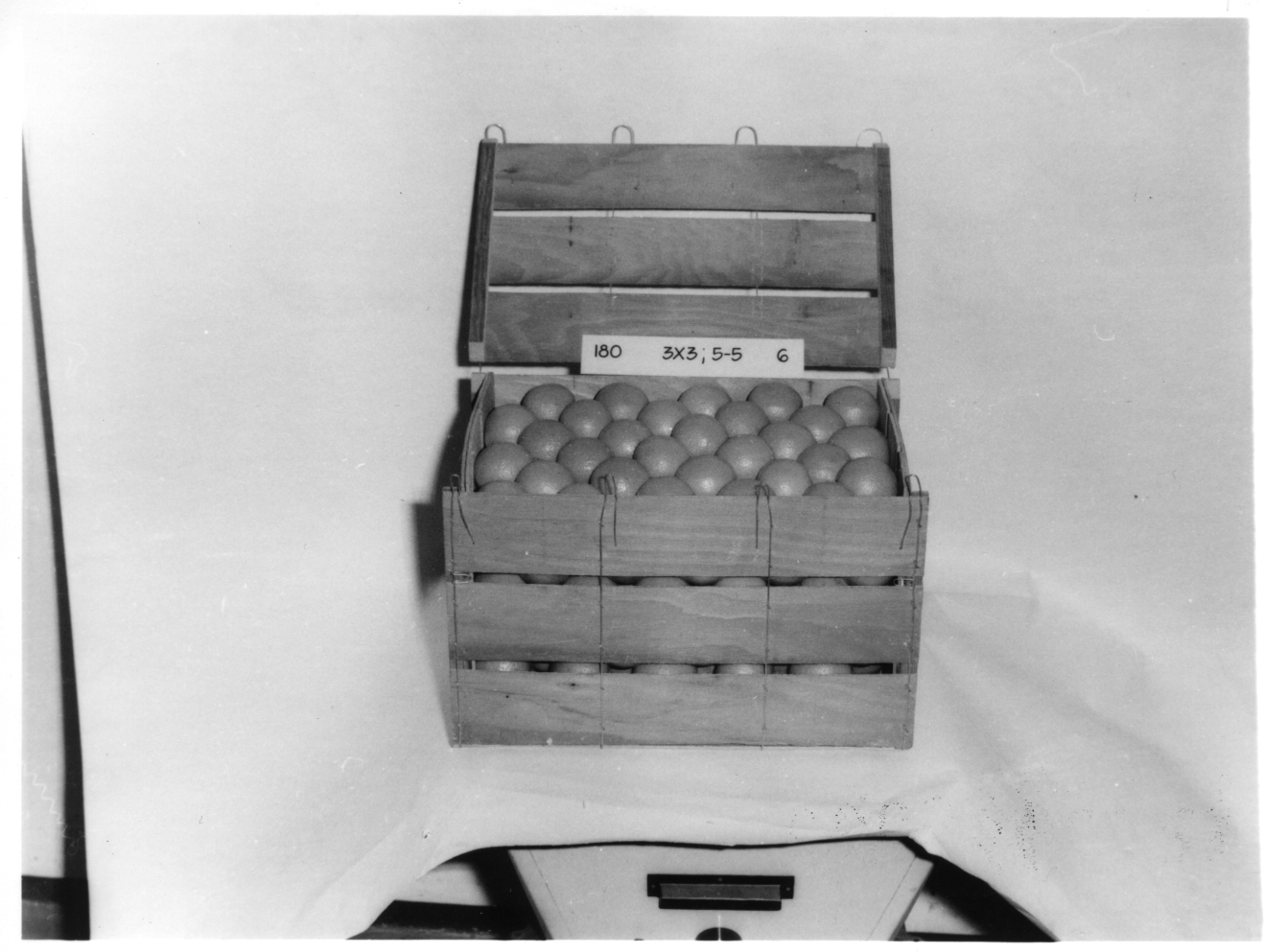

Through the 1950s to 1970s, the citrus industry gradually changed from wooden bushel cases to smaller volume (0.8 bushel) wire bound wooden Bruce boxes, then to the current fibreboard cartons. This required evaluation of packing systems used overseas (eg assessment of the Canadian standard case in 1962–63), and development of different packing and handling techniques.

Over-packing to achieve higher carton weights, especially for export to Singapore and Malaysia was a common occurrence and adversely impacted on fruit quality. This led to vibration packing and use of tray packs.

Post Harvest Research for Export Market Development

Poor export outturns in 1988 stimulated an extension program to improve postharvest handling, resulting in improved export outcomes in 1989. The Federal Government also approved the introduction of a quality control program for export fruit that enabled packers to get an “Approved Quality Assurance” status.

Subsequently a research program led by Mr Barry Tugwell and Mr Peter Taverner was developed to overcome postharvest technical problems associated with the more lucrative USA and Japan export markets. This involved fungicide and oil treatments, packaging, fruit quality aspects for in transit cold sterilisation, and protocols for shipment and logistics.

Commencing in 1993, a program of packing shed assessment was conducted by Mr Jim Hill using an “Instrumented Sphere” to measure damage points along grading and packing lines. This technique identified packing line fruit injury points, and in combination with specialist rectification advice, was able to significantly reduce fruit damage across South Australia’s citrus packing sheds.

Image: Citrus packed in a wire bound Bruce box by L.D. Jarrett – Oct 1965. Source: PIRSA image 103511.

For many years, new information about post harvest technology for citrus packers and processors was provided via the Packing Shed Newsletter (No 1 in December 1979 to No 52 in December 1993), which was later renamed the Citrus Packer Newsletter. Initially edited by Mr Kevin Gillespie and later Mr Peter Taverner, several editions were produced each year by the SA Department of Agriculture/SARDI. It was distributed nationally to packers until Vol 114 published in June 2015.

Irrigation and Drainage

From settlement of South Australia until WW1, most citrus orchards around Adelaide were located in river valleys where simple pumps or water diversions were used to flood water from streams into orchards to supplement natural rainfall. Improvements in irrigation and pump technology post WW1 allowed further development of mainly flood irrigation systems.

The rapid development of irrigation technology post WW2 (mainly in River Murray irrigation districts) resulted in a move to portable or permanent overhead sprinkler systems. Subsequently from the late 1960s, drippers and under tree sprinklers became the main water distribution system.

Image: Furrow irrigated citrus – 1950. Source: PIRSA image 106629.

Uniform flood application of water across a field was difficult, especially on light textured soils of the “highland” areas along the River Murray (where most citrus was planted). Uneven and excess water application frequently occurred, contributing to rising water tables and surface salinisation. Serious salinity problems killed trees, and required abandonment of lower lying land or installation of sub surface drains.

Overhead sprinkler irrigation was used increasingly from the 1950s and gave more uniform water application on the sandier, lighter textured soils. Loxton Irrigation Area was one of the first to use overhead sprinklers. Water was supplied to properties using low pressure piping, then pressurised on each property to operate sprinklers. Loveday was the first irrigation district to use low pressure pipelines rather than open channels to deliver irrigation water to properties.

In the 1960s, Department of Agriculture researchers Mr Bill Harris and Mr Max Till, used pressure testing and other techniques to improve the efficiency of sprinkler irrigation systems.

Overhead irrigating with high salinity River Murray water was a problem after floods (such as 1956),when high salinity water drained back into the river. Also during low flow periods such as 1967, high salinity resulted in significant defoliation of citrus trees, poor yields and quality. An alternative to overhead sprinkler irrigation was needed.

From around 1971, drip and under tree micro irrigation systems were developed, led by the plastics industries with factories based near Adelaide. These systems offered potential for greater precision in water application. The plastics industry also introduced PVC pipe systems that could be more cheaply and easily installed.

Collaboration between equipment manufacturers and the irrigation team at Loxton Research Centre (under the leadership of Irrigation Extension Officer, Mr Keith Watson) developed a comprehensive array of initiatives that improved irrigation efficiency and water management. This collaboration also led to establishment of the Irrigated Crop Management Service.

Image: Mr Max Till, Irrigation Research Officer pressure testing overhead sprinklers in citrus. Dec 1965. Source PIRSA image 103545.

This irrigation program fostered widespread adoption of under tree sprinkler and dripper irrigation systems in the SA citrus industry. Evaluation of drippers and under tree sprinklers from Israeli manufacturers was particularly important. Introduction of soil moisture monitoring and irrigation scheduling equipment greatly improved soil moisture management, and irrigation efficiency.

Dripper systems were further enhanced by using them to periodically apply soluble nutrients and create Intensive Fertigation Systems. These reduced fertiliser application costs and provided a more consistent way of supplying nutrients to trees.

The Martinez Open Hydroponics system (developed in Spain by Dr Rafael Martinez) for citrus was introduced to Australia in 1999 and is gradually being adopted. This applies nutrient and water solutions through a dripper system, but pulses applications to trees throughout the day depending on tree water demand. This system normally uses a higher planting density of 1,000 trees /ha.

While hydroponic systems achieve greater tree growth, higher yields, and more consistent production from year to year, there are additional costs and risks. More expensive and sophisticated nutrient injection and soil monitoring equipment is required. Because of the smaller root volume, trees are at greater risk of stress should a breakdown to the water and nutrient supply system occur. (For further information, see “Open Hydroponics : Risks and Opportunities”; by S. Falivene; NSW Department of Primary Industries; June 2005).

More information about development of improved irrigation systems in River Murray irrigation districts, is available from the “Irrigation development and management in South Australia’s Riverland” article located in the water resources section of the Agricultural History web site.

Tree Nutrition and Soil Management

Green manure crops for improved soil structure

Assessment of permanent sod cultures to overcome soil degradation created by frequent cultivation of orchards commenced at Berri Experimental Orchard in 1928, and was expanded at Blackwood Experimental Orchard in the 1940s and 1950s. This research fostered gradual adoption of permanent inter-row sod cultures in orchards over the next 30 years.

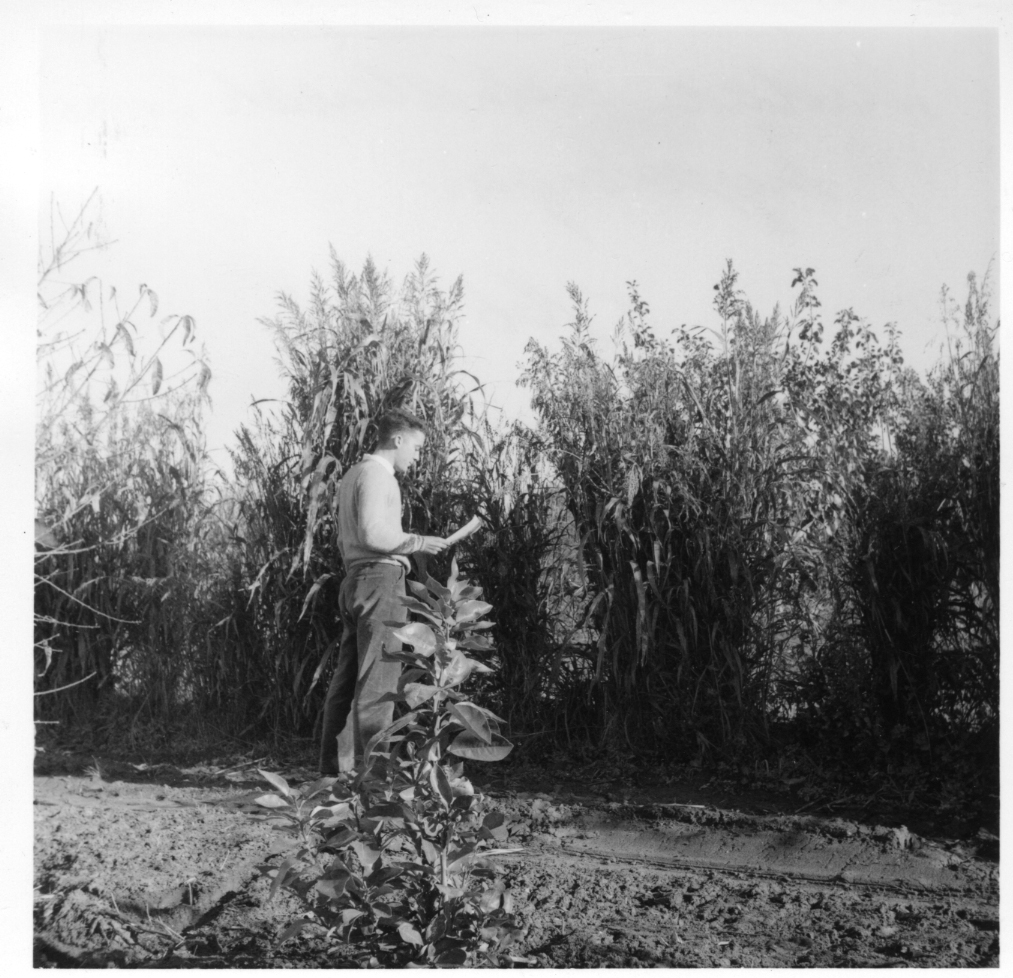

Associated with inter row sod cultures was the assessment of tall growing grasses (eg Sudax and Bana grass) planted between rows as a temporary windbreak to protect young trees during orchard establishment. These techniques along with synthetic shade cloth materials were assessed during the 1970s and 1980s.

Image: Sudax grass being used as a windbreak in a young orchard. Loxton Research Centre May 1966. PIRSA ID 103530.

Adoption of Nitrogen Fertilisers

In 1919, major citrus manuring trials began at Berri Experimental Orchard. Early adoption of nitrogen fertiliser applications began in the mid 1920s. In 1928, a major overhaul of these Berri plots was undertaken to add evaluation of sulphate of ammonia, blood manure and green manure crops.

The improved tree vigour and greater drought tolerance attained with sulphate of ammonia (nitrogen) applications resulted in trials being established on 6 citrus properties by 1930, and use of this nitrogen fertiliser was rapidly being adopted by citrus growers.

Comparison trials of urea and sulphate ammonia applications commenced at Berri in 1957–58, subsequently leading to the adoption of the lower cost urea.

Traditionally nitrogen fertilisers were applied in July when soils were cool and root growth slow. Across the 1980s and 1990s, nitrogen application timing was moved to early spring when tree uptake occurred more efficiently. This in conjunction with leaf analysis contributed to a dramatic reduction of nitrogen application rates, improved tree and fruit growth, and reduced nitrogen contamination of drainage water.

Nutrient Analysis and Fertiliser Application Forecasting

Establishment of soil and tissue analysis laboratories at Loxton and Northfield was critical for improving nutrient management in the SA citrus industry. The Mill Laboratory Annex of Loxton Research Centre was established in the mid 1960s and moved to the main Loxton Research Centre with construction of a new office and laboratory complex in 1981 Laboratory services were managed by Mr Trevor Glenn and Mr Tony Zimmerman. The tissue analysis from these centres provided orchardists with vital nutrient data over the next 40 years.

Leaf analysis surveys (by Dr Ben Robinson in conjunction with district horticultural advisers) were undertaken during the 1970s and 1980s to validate plant test standards used in North America and Europe, and adapt them for South Australian conditions. This led to the publishing of national standards for leaf analysis in horticultural crops (“Plant Analysis: A Manual” by Doug Reuter and Ben Robinson, 1986).

Following this validation work in the 1980s, the use of leaf analysis within the citrus industry was adopted through a series of grower training sessions run by District Advisers and Mr Peter Gallasch. This included an interpretation service to translate leaf analysis results into fertiliser use advice.

Over many years, Mr Peter Gallasch further improved the accuracy of fertiliser recommendations by introducing computer modelling to produce data on an individual block basis rather than a district average. In addition to leaf analysis data, crop load for the past and coming season, and other block information was used to more accurately predict the nutrients required for the coming season. This methodology resulted in some dramatic reductions in fertiliser use and cost, particularly for nitrogen.

Mr Peter Gallasch also developed nutrient analysis standards for citrus juices. This enabled tree nutrient levels to be assessed in June rather than November when leaf tissue samples are normally taken. This provided information about tree nutrient needs close to the best fertiliser application time of August – September. At this growth stage, crop load being carried for the current season is evident and can be taken into account when calculating fertiliser application rates.

Improved knowledge of soil and water interactions along with better irrigation management has greatly reduced the range of nutrition difficulties experienced by citrus orchardists.

Micro Nutrients

Zinc deficiency trials using foliar sprays commenced at Berri Experimental Orchard in 1939 to overcome this leaf mottling problem and improve yields. These zinc experiments were expanded in 1945 with additional experiments in manganese, copper and iron treatments. These trials led to the widespread adoption of micro nutrient treatments in citrus orchards.

Crop Management and Regulation

Crop Regulation

During the first half of the 20th Century, cincturing of the bark on tree limbs was commonly used as a technique to manipulate the fruit load on citrus trees. In 1923, experiments to use cincturing (in October and at full bloom) were used to improve fruit set on shy bearing trees at Berri Experimental Orchard. Overall growers found the technique of cincturing labour intensive, difficult to do and variable in its effectiveness.

Surveys conducted by Mr Peter Gallasch in 1969 revealed that growers found the alternate heavy and light cropping pattern of Valencia oranges was one of the most significant problems they faced. Initially trials were established to use different harvest times to reduce this problem, and these proved successful.

An alternate technique was to chemically thin heavy crops at the fruitlet stage. Trials using the plant growth regulator ethephon, which had not been used in citrus previously, would provide an easier way to manage alternate cropping. Several trials in the 1970sidentified optimal concentrations and application timings. It took many years of research and field trials in SA and NSW to generate the data for registration of ethephon (EthrelR) use in citrus across Australia.

The use of ethephon in early mandarins in Queensland also proved very effective in improving fruit size and regulation of crop load.

The development of quadrats for measuring fruitlet densities on trees at critical stages of fruit development also provided a valuable new methodology that would be used industry wide for forecasting crop loads.

Natural growth regulators have also been used to loosen fruit on trees in experiments for mechanical harvesting. These experimental machines rely on butt or limb shaking, or air blast to remove fruit from trees. Mechanical harvesting systems are used for juicing oranges in Florida. However damage levels and economics experienced with mechanical harvesters in Australia have shown further development is needed before adoption can occur.

Crop Forecasting

Crop forecasting was developed in the 1990s with Mr David Cain from the Citrus Board of SA playing a pivotal role. The aim was to predict fruit volumes available for export so appropriate volumes of shipping capacity could be reserved in time for harvest.

Both Citrus Board inspectors and Department of Agriculture staff were used to collect fruit densities in orchards. Data was collected from several properties in each major growing district. Problems with reliability of forecasts were being experienced.

Mr Peter Gallasch reviewed the forecasting methodology and developed computer predictive modelling, incorporating information about previous crop loads and extreme weather events.

To further improve reliability of crop forecasts, personal estimates of selected very experienced citrus personnel were incorporated. This process was managed using an expert panel that met several times during a production season, and developed a consensus crop estimate.

Fruit Size Enhancement

Growth of export markets in the late 1980s focussed industry on improving navel fruit size to obtain better returns. In the 1990s, trials were established to assess the use of hormonal growth regulators (auxins and gibberellic acid) using different rates and timings, and to assess residue levels. Both growth regulators were effective in improving fruit size, but only with the use of specific timings, rates and application methods. In addition to producing less and larger navel fruit, gibberellins slow rind ageing, important for USA markets.

Tree Training

During a visit to Israel in 1988, Mr Peter Gallasch observed a technique of branch thinning in mandarins to improve sunlight penetration into the tree canopy. This technique was subsequently promoted and adopted for Imperial mandarins in Australia, successfully improving fruit size. While overall yields were reduced to a degree, improvements in fruit size and quality delivered higher net returns.

Skirting

Citrus exports to Japan in the 1990s revealed a problem of fruit infestation with the pest Fuller’s Rose Weevil. Experiments were conducted on the effects and benefits of tree skirting. This provided recommendations on the optimal height and timing for skirting of Navel oranges.

Growers expressed concerns about loss of productivity associated with skirting lower fruit from the tree. Investigations revealed that trees compensated with growth of additional fruit higher up, and the net impact on crop was minimal. Fruit quality and size was improved.

Dwarf trees, hedging and high density orchards

One of the first Washington Navel tree spacing trials was planted at Loxton Research Centre in 1963 (with distances of 7.3 X 7.3 m, 7.3 X 5.5 m, 7.3 X 4.4 m, 7.3 X 3.7 m), and harvesting commenced in 1968. This provided basic information on performance of higher density orchards.

Image: Citrus irrigation and planting distance trial. Loxton Research Centre. Sept 1973. PIRSA Image 104378.

Research showed that harvesting was a major cost of production. Taller trees were more expensive to harvest. Innovations like aluminium bow ladders that were contoured to the shape of the tree canopy reduced the frequency of ladder movement, but they only provided a marginal benefit in reducing harvest costs.

Smaller trees offered significant reductions in per tonne cost of harvesting. Closer planting of smaller trees required higher investment /ha for orchard development, but provided higher overall production per hectare. Higher early yields also gave quicker “payback” on orchard development costs. Greater tree densities offer the opportunity for improved orchard profitability.

Canopy management strategies were promoted and the industry adopted use of hedging and a more science based approach to planting distances. Studies identified optimum tree spacing taking account of tree growth rate, cost of nursery trees, and their early care parameters to give the most economical and manageable outcomes.

Through the 1980s, tree planting densities gradually increased from 200 trees/ha to approximately 520 trees/ha. More recent hydroponic citrus production systems use tree densities as high as 1,000 trees/ha.

Consequently there was interest in reducing tree size. One controversial strategy was to inoculate Valencia trees with a mild strain of the Exocortis viroid to slightly stunt growth. Ten year old trees were shown to be 20% smaller. Work at CSIRO Merbein examined the use of genetic dwarf rootstocks.

Subsequently commercial sourcing of dwarfing rootstocks from California resulted in industry adopting Troyer and Citrange 35 to give a 20–25% reduction in tree size.

Frost Management

Severe frosts can cause significant damage to citrus trees and fruit, occurring more frequently in low rainfall seasons.

A major frost in 1983 resulted in severe damage to a large number of trees causing extensive splitting of limbs. A major pruning extension program, including a training video produced by Mr Peter Gallasch, was launched to assist growers revitalise frost impacted orchards.

Frost damaged fruit is unsaleable and has a much lower density than good quality fruit. During packing, flotation is used to remove frost damaged fruit from the packing line.

Weed Management

Through the 1960s, a combination of knock down and residual pre-emergent herbicides (bromacil and diuron) were adopted by the citrus industry for broad spectrum orchard weed control. These were applied using specially adapted under tree boom sprayers.

During the 1970s, glyphosate became available as a suitable herbicide for a range of problem weeds. Improved techniques were developed for its use to control a wide range of weeds.

Research identified a considerable variation in the efficiency and precision of herbicide spray jets. Recommendations were developed on the jets that gave the best application results and how frequently they need to be changed.

Citrus Export Market Development

One of the earliest records of citrus exports from South Australia was from the London Wine and Produce Department in August 1897. It reported on the outturn of oranges at the Covent Garden Market, mentioning generally sound quality of the oranges, being critical of the poor grading, and commenting on the competition with local summer fruits in the UK.

Early exports of citrus were slow to develop, with New Zealand being the main market. In 1907, South Australia exported 930 bushel cases of oranges and lemons, and by 1927 this had expanded to 2,067 cases (compared with exports of 496,685 bushels of apples in 1907). During the 1930s, Mr Peter van Velsen was appointed an Honorary Commissioner to inquire into and develop export of citrus and other SA fruit to the Dutch East Indies (Indonesia). By 1937, SA’s citrus exports were gaining momentum, up to approximately 190,000 cases annually, with 91% going to New Zealand and the balance to the UK. (Source SA Department of Agriculture annual reports).

Rapid expansion of plantings post WW2 stimulated growth of exports. Through to the mid 1950s, Australian exports of citrus to NZ continued to grow, with SA’s share of this market being stimulated by sporadic outbreaks of fruit fly in NSW and Victoria. In 1964, SA exported 540,000 bushels of citrus with 351,000 bushels going to NZ.

Image: Orange Ceremony on the Steam Ship Ballarat. Commemorating export of citrus from South Australia, August 1934. PIRSA Photo 108805.

Exports of fresh citrus to the UK continued at a modest rate for many years. When the UK entered the European Economic Community in January1973, increased tariffs made Australian fruit uncompetitive in this market.

Sales of fresh citrus to Malaysia, Singapore and other SE Asia countries grew steadily in the 1970s and 1980s. Citrus exports to Japan were developed in 1986–87 with trial shipments of navel and Valencia varieties. Control measures for Fullers Rose Weevil were needed to allow market access to Japan. Trials to prove the efficacy of methyl bromide fumigation (for fruit packed for Japan) were conducted by Mr Barry Tugwell using an old fumigation unit at the Renmark railway station. Costly methyl bromide fumigation was subsequently replaced by “in transit” cold treatment of fruit.

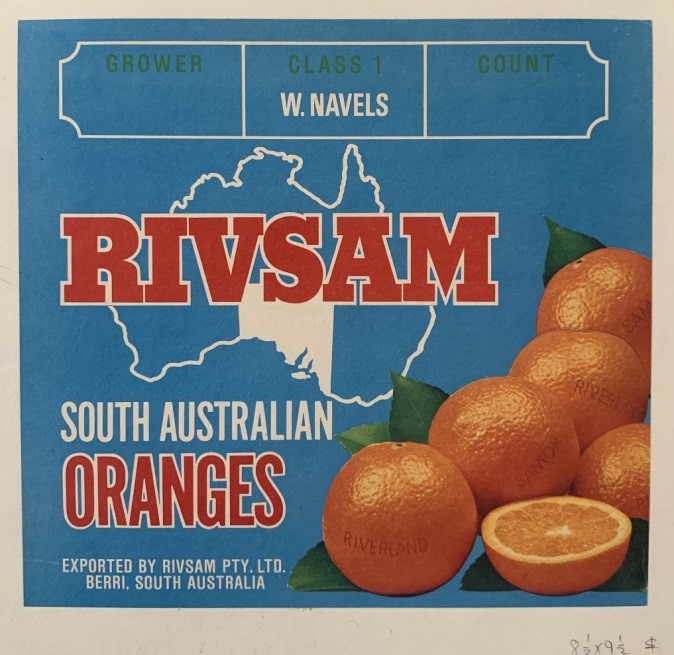

Establishment of Riv-Sam to grow Riverland citrus exports

Riv-Sam, a non-profit organisation was established in 1972 to develop the export of the State’s citrus production, a function previously handled by the South Australian Citrus Organisation Committee, the citrus industry statutory and regulatory authority (forerunner to the Citrus Board of SA).

Riv-Sam sold citrus on behalf of 15 South Australian Riverland cooperatives and private fruit packers representing some 2,000 shareholders. Based in Berri, Riv-Sam operated as a cooperative for the export of navel and Valencia oranges, Ellendale mandarins, Lisbon lemons and Marsh grapefruit.

Riv-Sam pursued markets in New Zealand, South-East Asia (particularly Singapore and Malaysia), Europe and the Middle East. Sales increased from $1.9m in 1976–77 to $4.1m in 1978–79, $5.9m in 1979–80 and $6.6m in 1980–81. This excellent result led to Riv-Sam winning a national export award for Outstanding Export Achievement in 1981. Mr David Andary was the inaugural Chairman (1972–1982) and Mr John Henwood was the General Manager of Riv-Sam. In 1978 Mr David Andary was appointed an Officer of the Order of the British Empire in the Queen’s Birthday Honours for services to the fruit industry.

Image: Riv-Sam package labels. Source: Riv-Sam.

Riv-Sam competed against other southern hemisphere suppliers (South Africa and Chile) that had lower labour costs. Riv-Sam’s success was based on establishing and maintaining a reputation for quality and dependability. Further, they were actively focused on overseas market development through in-market promotions (including in-store promotions), advertising in magazines and radio, along with regular travel to meet overseas customers and ensure a strong on-going relationship.

Another key success factor was Riv-Sam’s in-depth knowledge of citrus handling and storage. Poor packaging and storage of fruit can cause major export problems with mould and breakdown of fruit. The South Australian industry had developed expertise in treating fruit with fungicides to prevent growth of penicillin mould.

Riv-Sam also developed its own packaging for citrus export, the Bruce box, a wire-bound wooden crate with hardboard ends that was particularly suited to high temperature and humidity storage conditions. This was particularly important as fruit is easily damaged in-transit and its arrival in optimum condition is important for continuing sales success. The Bruce box also provided a significant marketing advantage over competitors because of its distinctive appearance.

Riv-Sam also developed expertise in scheduling the harvesting, packaging and shipment of fruit to ensure quality standards were maximised. Further, Riv-Sam packaging was designed for efficient use of cargo space in shipping containers.

In addition to Riv-Sam, there were two other private packers who were strong exporters of Riverland citrus. These were Yandilla Park Citrus(owned by East Africa Coffee) at Renmark and operated by Mr Andrew Weigall, Chairman. Their brand was Vitor (an acronym for vitamin orange). The other company was Kangara Citrus of Murtho.

Mr Andrew Weigall was inducted into Citrus Australia’s Hall of Fame in 2019.

With other developments occurring in the citrus industry, Riv-Sam’s role gradually reduced over time and it was deregistered as a cooperative in 2011.

Citrus Exports to the USA

Development of fresh citrus exports to the USA began in 1986 when Mr David Cain, CEO of the Citrus Board of South Australia (1980 to 1999) made a personal visit to the USA. Through the US Consulate in Canberra, meetings were arranged with senior staff of APHIS (Animal & Plant Health Inspection Service) in the USA to discuss barriers for fresh Australian citrus entering the USA market. Subsequently, a delegation of APHIS officials visited Australia in 1987, being hosted to Riverland citrus production districts by Mr David Cain and Dr Rip van Velsen.

Fruit fly was a key concern for importation into the USA, and SA’s “Fruit Fly Area Freedom” for the Riverland was ultimately recognised. The selection of post harvest oil treatments by Mr Peter Taverner for improved pest control (SARDI Research Report No 5, “Commercial Trial of Citrus Post Harvest Oil for Removal of Pests” by P. Bailey and P. Taverner, 1995) was particularly valuable. Research work was required with a range of other pests such as mealy bug and various scale insects. Considerable post harvest research led by Mr Barry Tugwell into rot controls also assisted in achieving satisfactory fruit outturn in the USA market.

There were numerous visits to the USA and meetings with US citrus organisations (eg California Citrus Quality Council and Sunkist) to negotiate biosecurity issues and address marketing problems. The USA citrus industry was keen to have reciprocal access to Australia’s fresh citrus markets during the southern hemisphere summer, providing a significant incentive for this trade to be established.

Australian Horticulture Corporation regulations were used to enable appointment of Riversun Export Pty Ltd as the export coordinator from Australia. Riversun Export Pty Ltd was formed in 1992 by a group of citrus exporters and packers based in the Riverland of SA and Sunraysia district of Victoria as the export coordinator from Australia, with marketing in the USA being through the DNE Group. The Chair of Riversun was Mr Peter Walker, a citrus grower from Sunlands, Waikerie. The General Manager of Riversun was Mr Steve Allen.

Benefits of the Riversun coordinated programs included:

- Marketing plans – planning commencing 6 months before harvest with volumes predetermined in accord with market requirements; pre-season marketing and constant assessment of market conditions.

- Shipping programs – tailored to marketing plans, cost effective and reliability of delivery. Use of dedicated break-bulk refrigerated charter shipping to the USA. Riversun chartered ships which were loaded at Port Adelaide.

- Coordinated supply to the market – no fragmentation of multiple Australian suppliers to the US or individual US retailers playing off one supplier against another. All sales to the US were made in US dollars.

- Promotions – promotion of a large volume through a single brand resulting in greater efficiencies and impact.

- Ability to meet specific customer needs – a large supply base enabled long lines of consistent quality product. Quality training programs were undertaken for packing houses to ensure a standardised approach to quality and packaging.

- Uniform and timely industry response to quarantine issues.

- Enables small growers to participate in a large, profitable market and share the benefits of critical mass.

- Communication to provide total transparency.

The first export consignment of a small number of containers occurred in May 1992. A critical consideration was obtaining permission for consignments with non-compliant levels of mould and blemish to be repacked in the USA rather than to be re-exported at considerable cost.

In 1994, major difficulties were experienced with 75% of consignments failing the 0.5% tolerance level for decay (rots) being applied by the USDA’s Agricultural Marketing Service. A delegation to the USA in August 1994 led by Mr David Cain (CEO of Citrus Board of SA) and Mr Barry Windle (General Manager, Horticulture, Primary Industries SA) identified onions being imported into the USA were allowed a 3% decay level tolerance for transit times of 10 days. The 0.5% tolerance level being used by the Agricultural Marketing Service was considered a non-tariff trade barrier. Following negotiation with US citrus industry organisations and the USDA, the decay tolerance was adjusted to 3% making Australian citrus exports to the USA economic (Source: Final report from the South Australian citrus industry delegation to the United States: on navel orange export problems, 3–10 August 1994; Cain D.M. & Windle B.E.; 1994.)

In 1995, national citrus exports to the USA had reached 5,000 t, and by 1998 exceeded 25,000 t annually. Exports to the USA peaked in 2007 at 35,000 t, but then declined following the Global Financial Crisis mainly because of the $A exceeding parity against the $US in 2009 to 2011. Further, the opening of the US market to cheaper imports from South Africa (1997) and Chile (2009) also created major competition for Australian fruit. By 2016, exports of citrus to the USA had declined to below 10,000 t per annum.

In September 2014, citrus producers in the Riverland voted to wind up Riversun Exports. Chairman Peter Walker commented that Riversun Exports had served its purpose.

As a result of his industry leadership and role in fostering development of citrus exports to the USA, Mr David Cain was awarded a Public Service Medal in June 1999.

Recent Citrus Export Growth

Expansion of fresh citrus exports from Australia since 2013 has focussed on Asia and can be attributed to:

- Growing affluence in many South East Asian countries.

- Recognition of the quality and food safety aspects of Australian citrus.

- Establishment of Free Trade Agreements with China, South Korea, Japan, and Indonesia reducing tariffs on Australian fruit entering these countries.

- Recognition of the Riverland region as a “Fruit Fly Free Area” by China, Indonesia, USA, Thailand, Japan and NZ, enabling access of fruit into these markets.

Between 2014 and 2017, Australian exports of oranges increased significantly with greater demand from China, Japan and other Asian markets. This has stimulated a new resurgence in Australia’s citrus industry plantings.

According to Horticulture Innovation’s 2018–19 Australian Horticulture Statistics Handbook, citrus was Australia’s third largest fresh horticultural export by value in 2018–19 worth $447.5m (oranges $308.1m and mandarins $139.4m). Australia’s top horticultural export in 2018–19 was almonds ($675.0m) followed by table grapes ($555.2m).

Table 3: Australian Orange Exports

| Year Ending June | 2017 Value | 2018 Value | 2018 %YoY | 2019 Value | 2019 %YoY |

|---|---|---|---|---|---|

| Production (t) | 506,391 | 526,079 | +4% | 528,095 | <1% |

| Export Volume (t) | 164,044 | 190,037 | +16% | 188,056 | (-1%) |

| Export Value ($m) | $223.8 | $280.1 | +25% | $308.1 | +10% |

Source: 2018–19 Australian Horticulture Statistics Handbook, Hort Innovation

Table 3 highlights the very significant increase in the volume and value of Australian orange exports over the period 2017 to 2019, which far exceeds any growth in production. Hence a greater proportion of production is being exported (32% in 2017 rising to 35.6% in 2019) with the export value per tonne increasing.

Table 4: Australia fresh orange exports 2017–2019 by country (Tonnes)

| Year Ending June | 2017 | 2018 | 2019 |

|---|---|---|---|

| China | 34,051 | 50,204 | 61,333 |

| Japan | 33,021 | 37,215 | 33,474 |

| Hong Kong | 25,773 | 26,896 | 30,870 |

| Malaysia | 11,417 | 12,209 | 8,691 |

| Singapore | 9,929 | 8,249 | 7,895 |

| Other | 49,853 | 55,270 | 45,793 |

| Total | 164,044 | 190,043 | 188,056 |

Source: 2018–19 Australian Horticulture Statistics Handbook, Hort Innovation.

The growth in sales to China has been significant. For the year ending June 2019, 33% of exported fresh oranges went to China. Sales grew by 47.4% in 2018 (YoY) and by 22.1% in 2019 (YoY).

Table 5: Orange exports by State (Tonnes)

| Year ending June | 2017 | 2018 | 2019 |

|---|---|---|---|

| Victoria | 76,536 | 89,127 | 89,138 |

| South Australia | 58,928 | 68,121 | 60,347 |

| New South Wales | 23,683 | 27,918 | 34,787 |

| Queensland | 2,633 | 1,579 | 2,054 |

| Western Australia | 1,917 | 2,550 | 1,730 |

| Other | 346 | 748 | <0.5 |

| Total | 164,044 | 190,043 | 188,056 |

Source: 2018–19 Australian Horticulture Statistics Handbook, Hort Innovation.

In 2019, Victoria provided 47.3% of orange exports, SA 32% and NSW 18.5%.

SA produced 28% of Australia’s oranges in 2018–19.

Table 6: Australian Mandarin Exports

| Year Ending June | 2017 Value | 2018 Value | 2018 %YoY | 2019 Value | 2019 %YoY |

|---|---|---|---|---|---|

| Production (t) | 154,266 | 160,343 | +4% | 156,914 | -2% |

| Export Volume (t) | 51,041 | 63,961 | +25% | 59,471 | -7% |

| Export Value ($m) | $100.1 | $139.0 | +39% | $139.4 | <1% |

Source: 2018–19 Australian Horticulture Statistics Handbook, Hort Innovation

Table 6 shows the significant growth in mandarin exports. For the year ending June 2019, 27% of exported mandarins went to China and 12% went to Thailand.

Table 7: Australia fresh mandarin exports 2017–2019 by country (Tonnes)

| Year Ending June | 2017 | 2018 | 2019 |

|---|---|---|---|

| China | 9,461 | 19,337 | 16,050 |

| Thailand | 7,884 | 9,237 | 7,482 |

| Hong Kong | 3,692 | 4,926 | 4,755 |

| UAE | 4,703 | 3,385 | 4,537 |

| USA | 3,586 | 4,279 | 4,105 |

| Other | 21,714 | 22,795 | 22,534 |

| Total | 51,041 | 63,960 | 59,471 |

Source: 2018–19 Australian Horticulture Statistics Handbook, Hort Innovation

As with oranges, growth in mandarin exports to China has been rapid over the period 2017–2019.

Table 8: Mandarin exports by State (Tonnes)

| Year ending June | 2017 | 2018 | 2019 |

|---|---|---|---|

| Queensland | 30,525 | 44,374 | 36,820 |

| South Australia | 10,695 | 15,210 | 16,956 |

| Victoria | 7,324 | 3,472 | 4,377 |

| New South Wales | 418 | 839 | 1,185 |

| Western Australia | 30 | 42 | 132 |

| Other | 2,048 | 23 | 1 |

| Total | 51,041 | 63,960 | 59,471 |