South Australia's Potato Industry

From 1880 to WW2, South Australia produced approximately 5% of Australia’s potato crop. Improvements in irrigation technology in the 1950s enabled expansion of potato production on the Northern Adelaide Plains where sandy soils and low frost incidence give almost year-round production. Washed pre-packed potatoes emerged as an innovative marketing initiative in the 1960s, expanding fresh sales and production.

Adelaide Hills potato harvesting and bulk handling field day 1959 – strategies to overcome post WW2 shortages of farm labour. Source: PIRSA photo ID 105107

Success of this marketing model encouraged growers to commence developing larger potato enterprises in the Murray Mallee and Riverland in the 1980s. This created a 450 km zone along South Australia’s eastern border between Waikerie and Mt Gambier that provides climatic districts and soils (using irrigation water from underground aquifers or the River Murray) suited to year-round fresh potato production.

Through the 1980s and 1990s, there was significant growth of potato processing in South Australia. Smith’s Snackfoods built a new crisping plant at Regency Park in 1986 which has had many subsequent upgrades. A French fry freezing plant was developed with Safries at Penola in the 1980s, later sold to McCains Foods in 1992, then closed in 2013 with processing consolidated at McCains Ballarat plant. While domestic fresh potato sales dominate South Australia’s potato industry, crisp and French fry manufacture along with fresh potato exports and seed production continue to be important sectors of the South Australian potato industry.

Larger properties gave economic advantages through use of centre pivot irrigators (reduced labour), larger machinery, and longer rotations for improved soil borne disease management. These factors delivered yield and tuber quality benefits while ground storage (deferred winter harvest) enabled year-round supply.

Improvements in seed potato quality through better virus management and seed potato certification systems have also lifted yields.

Today 30-35% of Australia’s potatoes are produced in South Australia with 15% of Australia’s production (2021-22) being sourced from the Riverland and Murray Mallee regions, while 10% is produced in the South East1. South Australia is now the main supplier of fresh washed potatoes onto the Eastern seaboard of Australia and a significant supplier of potatoes for French fry, crisp manufacture, and certified seed.

SA Government contribution to the potato industry

The South Australian Government via its agriculture agencies – the Department of Primary Industries and Regions (PIRSA) and South Australian Research and Development Institute (SARDI) – has been a major contributor to growth of the SA potato industry (see below for full list of agency names).

The earliest support came with the appointment of a Horticultural Inspector at Mt Gambier in 1908 to improve seed production. This was followed by the importation of 12 new potato varieties from the UK in 1909.

The first part time potato research officer was appointed in 1949, followed by a full-time researcher in 1959. Between 1970 and the early 2000’s, a wide range of research and extension projects were delivered to South Australia’s potato industry by various staff.

This article chronicles how these research and extension programs assisted development and growth of South Australia’s potato industry, particularly between the late 1970s and 2010. Key research and extension programs that contributed to the SA’s potato industry expansion included:

- Overcoming poor cooking qualities through research (commencing 1982) to improve crop fertilizing and nutrient response data. This strategy achieved significant quality and yield improvements.

- Development of soil borne disease tolerance levels and management strategies to minimise tuber wastage due to blemish.

- Investment by SARDI in automated laboratory systems for soil, plant tissue and virus testing. These systems improved laboratory response times, reduced test costs, aiding seed certification and on farm decision making about nutrient and disease management.

- Variety assessment and quality improvement.

- Providing a crop monitoring service to improve productivity of South East French fry growers. Staff trained by this service would go on to establish and operate private crop monitoring businesses.

The South Australian Government has gradually reduced investment in potato industry support services since the early 2000s. South Australia’s potato industry has subsequently moved to funding key research and extension projects through national levy funds. A network of private agronomists and crop input suppliers now work closely with major growers to improve crops, achieve better business performance, and grow South Australia’s potato industry.

Changing government agency names

Changing government agency names

During more than 120 years, there have been numerous changes to South Australia’s agriculture agency names. To simplify identification of the two main agriculture agencies throughout this document, the current acronym PIRSA is used for Primary Industries and Regions South Australia, while SARDI represents the research agency South Australian Research and Development Institute.

Following is the array of names used since establishment of South Australia’s government agencies servicing agriculture and potato industries:

- The initial organisation servicing agriculture industries was the Bureau of Agriculture established in 1888.

- Department of Agriculture (South Australia) – first established 1902.

- Department of Agriculture and Fisheries South Australia – amalgamation between Department of Agriculture and Department of Fisheries 1975.

- Department of Agriculture South Australia – returned to this previous name 1979.

- Primary Industries South Australia (PISA) – merges with Woods and Forests Department 1992.

- South Australian Research and Development Institute (SARDI) – 1992 – separation of research activities from other functions of South Australia’s agriculture agency. SARDI is still operational.

- Primary Industries and Resources South Australia (PIRSA) – 1997.

- Primary Industries and Regions South Australia (PIRSA) – 2011. Current name of South Australia’s agriculture agency.

Background

Potatoes were introduced as a key vegetable crop by First Fleet settlers, initially in the Parramatta district west of Sydney. Potatoes became a staple crop commonly grown in home gardens across Australia.

Harvested potatoes packed in hessian bags at Woodside, 1930. Hessian bags were used for transporting potatoes until the introduction of bulk handling and smaller consumer size plastic bags in the 1960s. Source: State Library of SA Image 57990

Through to the 1940s, South Australia’s potato industry was concentrated in the South East near Mt Gambier, and Mt Lofty Ranges east of Adelaide, utilising higher rainfall in these districts. South Australia’s potato industry has grown with irrigation, and eras shaped by historic, social, technological, economic, and marketing factors:

- Waves of urbanisation that displaced producers from horticulture districts close to Adelaide, forcing potato growers to move to more remote and larger scale production districts across different climate zones.

- Emergence of new irrigation, nutrition and crop management technologies that improved yields, quality, and productivity.

- Evolution of washing and packing technologies that enabled larger scale automated washing and packing plants with reduced labour costs.

- Mechanisation of potato production accelerated through the 1950s and 1960s with the adoption of seed cutting machines, multi row planters and harvesters. Larger properties enabled the use of more powerful tractors and wider more sophisticated machinery, most of which is now sourced from European manufacturers.

- Development of refrigerated road transport that enabled rapid supply of fresh potatoes to interstate wholesale markets and supermarket warehouses.

Growth of South Australia’s potato industry

The below table provides an overview of the growth of Australia’s and South Australia’s potato production since the 1880s. Of interest is the emergence of South Australia as a significant potato producing state since 1950.

Table 1: Potato area and production – Australia and South Australia 1880 - 20232

Table 1: Potato area and production – Australia and South Australia 1880 - 20232

Year | Australia | South Australia | SA tonnes as a % of Australia | ||

|---|---|---|---|---|---|

Area hectares | Production tonnes | Area hectares | Production tonnes | ||

1880* | 23,500 | 308,400 | 3,000 | 28,300 | 9.1% |

1890* | 37,700 | 302,900 | 2,600 | 24,200 | 7.8% |

1900* | 56,400 | 413,700 | 3,400 | 20,000 | 4.8% |

1910* | 55,500 | 393,200 | 3,300 | 18,900 | 4.8% |

1920* | 46,100 | 298,900 | 1,400 | 11,200 | 3.7% |

1930* | 50,200 | 348,000 | 1,800 | 15,200 | 4.4% |

1940* | 42,300 | 328,500 | 1,800 | 21,600 | 6.6% |

1950* | 54,200 | 477,900 | 2,900 | 41,600 | 8.7% |

1960* | 43,800 | 588,100 | 2,400 | 49,700 | 8.5% |

1970* | 43,300 | 761,800 | 3,200 | 79,900 | 10.5% |

1980* | 36,700 | 857,400 | 3,500 | 91,500 | 10.7% |

1990* | 40,600 | 1,177,900 | 5,100 | 161,300 | 13.7% |

2000* | 36,800 | 1,199,600 | 8,000 | 280,600 | 23.4% |

2010* | 36,400 | 1,278,100 | 11,900 | 358,700 | 28.1% |

2020** | 1,388,859 | 531,385 | 38.2% | ||

2023*** | 1,462,975 | 433,008 | 29.6% | ||

* Source: Australian Bureau of Statistics 71240DO001_201011 Historical Selected Agricultural Commodities, by State (1861 to Present), 2011.

**Source: Australian Horticulture Statistics Handbook 2019/20, Hort Innovation/Fresh Logic, Potatoes, P 391-397.

***Source: Australian Horticulture Statistics Handbook 2022/23, Hort Innovation/Fresh Logic, Potatoes, P 307-311.

National significance of SA potatoes

Potatoes are Australia’s most important vegetable crop with a farm gate value of $1,033.4m in 2022-23. Per capita consumption was 16.64kg in 2022-23, with 87% of Australian households buying potatoes, averaging 1.63kg of purchases per shopping trip3.

South Australia produced 433,088t of potatoes in 2022-23 with a farm gate value of $305.9m. This represents 29.6% of Australia’s 1,462,975t of potatoes valued at $1,033.4m in 2022-233.

The Riverland plus Murray Mallee, and South East districts are two of the largest potato production districts in Australia supplying 15% and 10% of national production respectively4.

Table 2: Australian Potato Production X State 2022-23*5

Table 2: Australian Potato Production X State 2022-23*5

State | Volume (tonnes) | Volume (national %) | Value ($m) |

|---|---|---|---|

Tasmania | 458,280 | 31.3% | $323.7 |

South Australia | 433,008 | 29.6% | $305.9 |

Victoria | 263,570 | 18.0% | $186.2 |

New South Wales | 158,891 | 10.9% | $112.2 |

Queensland | 80,960 | 5.5% | $57.2 |

Western Australia | 68,267 | 4.7% | $48.2 |

Total | 1,462,975 | $1,033.4 |

*Australian Horticulture Statistics Handbook 2022-23, Horticulture Innovation Australia Ltd and Fresh Logic; P309.

Most of South Australia’s fresh potatoes are marketed on Australia’s eastern seaboard in Melbourne, Sydney, and Brisbane. South Australia also exported 19,467t, or 48% of Australia’s 40,672t potato exports in 2022-23, most of which were destined for South Korea (50%) and the Philippines (21%)3.

South Australian growers also supply processing potatoes for the frozen French fry (McCain, Ballarat) and crisping (PepsiCo, Regency Park) sectors. Data on processing volumes are not readily available.

For comprehensive details of Australian potato production, value, marketing, and significance of various industry sectors and states, consult the Australian Horticulture Statistics Handbook. This is published annually by Fresh Logic for Horticulture Innovation Australia Ltd. See the 2022-23 handbook3.

South Australia’s area of potato plantings gradually expanded until the 1930s when decline occurred because of the Great Depression. Production grew during WW2 to supply armed services (see SA Potato Marketing Act section). In the three years from 1941-42 to 1943-44, the area planted to potatoes in SA increased from 4,800 ac (1,943 ha) to 9,000 ac (3,644 ha)6.

Following are major factors and eras in development of South Australia’s potato industry:

Natural rainfall vs development of irrigation technology

After South Australia’s settlement in 1836, potato production grew to supply the state’s population. Until the late 1800s production was concentrated in the South East and Mt Lofty Ranges where higher rainfall provided the best yields.

Electric motors and internal combustion engines began to power irrigation pumps in the early 1900s. Irrigation enabled potato production on the Adelaide Plains along the River Torrens east and west of Adelaide. Irrigation was also adopted in the Mt Lofty Ranges and South East to improve yields and profitability.

New turbine (and later submersible) pumps became available in the 1940s and 1950s, allowing access to irrigation water from deeper aquifers. This pump technology was critical for development of potato and vegetable production on the Northern Adelaide Plains through the 1950s and 1960s, and later the Murray Mallee in the 1980s and 1990s.

Large stack of potato bags for loading onto railway trucks at Mt Gambier railway yards, 1888. Through until the 1950’s, the higher rainfall South East was South Australia’s main potato production district.Source: State Library of SA Image B14730.

Improved transport and interstate marketing

Establishment of railway networks provided effective transport from country regions to cities. Expansion of the nation’s railway network by the 1880s allowed interstate marketing of potatoes to develop (see photo of potatoes stacked for loading at Mt Gambier rail yards – 1888). By 1914, the South East district was railing significant quantities of potatoes to Victoria, New South Wales and Western Australia7.

During the 1960s and 1970s, refrigerated road transport emerged as a faster and cheaper way to ship produce from South Australia to interstate cities such as Melbourne and Sydney. Refrigeration enabled supply of high quality fresh washed potatoes to distant markets. Improvements in highways, and the size, capacity, speed, and reliability of trucks has seen road transport replace railways for transporting fresh produce to interstate markets.

Urban and economic displacement

A series of urban and economic factors have changed the geography of South Australia’s potato production districts.

Commencing in the 1950s, rapid expansion of suburbs east and west of Adelaide along the River Torrens forced vegetable and potato growers to relocate to the Northern Adelaide Plains. Located 35 km north of Adelaide, the Northern Adelaide Plains offered larger properties suited to increased mechanisation and lower production costs, while sandier soils in conjunction with low frost incidence enabled almost year-round harvesting of potatoes. Sandier soils also produced a cleaner brighter tuber that is more attractive to consumers when presented in a washed prepack.

Several growers established washing and packing plants on the Northern Adelaide Plains in the 1960s, sourcing potatoes from networks of neighbouring growers.

By the 1980s, Adelaide Plains potato growers were looking to expand businesses further and searched for larger lower cost properties. The Murray Mallee offered opportunities with sandy soils, underground aquifers, lower cost land, and gradually developed as a major potato growing district.

Irrigation areas along the River Murray and Murray Mallee offered larger areas of land enabling long crop rotations to reduce the incidence of soil borne diseases. They also suited use of labour-saving centre pivot irrigators, larger planting, spraying, and harvesting machinery.

The Adelaide Hills ceased to be a major potato growing region in the 1990s. Higher land costs, inability to increase scale of production, and problems with nutrient rich run off draining into Adelaide’s water catchments were making it difficult for this region to compete. Demand for irrigated land by the cool climate wine grape industry resulted in most Adelaide Hills potato growing properties converting to wine grape production during the 1990s.

Another wave of urban encroachment has commenced on the Northern Adelaide Plains in the early 2000s. This was accelerated by construction of the Northern Expressway across the heart of the Northern Adelaide Plains between Waterloo Corner and Gawler. Since its completion in 2010, this new freeway has been a major stimulus for urban development around Northern Adelaide Plains towns (Virginia, Two Wells, Angle Vale, Gawler) due to fast easy commuting to Adelaide. This new wave of urbanisation is placing additional economic pressures on Northern Adelaide Plains potato and vegetable enterprises.

Mechanisation

Originally, potatoes were hand dug with forks, picked up into buckets, and packed into hessian bags (like those used for marketing grain). Bags were then hand sown before trucking to markets.

Tractor drawn potato lifters eliminated the back breaking process of hand digging. Ground driven, and later power take-off driven, potato lifters laid the crop in the row ready for “picking up” by hand. By the 1950s, harvesters were being adopted enabling lifting, grading, and packing potatoes into bags on the harvester.

Further innovation in the1950s and 1960s enabled harvesting into bulk bins for removal from the paddock by forklift or trailer, with handling, grading, and packing on a grading line located in a shed. This system offered further labour savings.

Post WW2 industrialisation of South Australia’s work force caused serious shortages of farm labour. Through the 1950s, PIRSA delivered a mechanisation program targeting grain, apple, and potato industries. This program introduced air blast sprayers to Australia, encouraged introduction of potato harvesters (see cover photo), and adoption of bulk handling with forklifts and bulk bins.

Fresh market innovation

Traditionally, potatoes were harvested when mature, packed in hessian bags, and marketed through wholesalers to retail outlets. Year-round supply to markets required storing autumn harvested tubers followed by grading, packing, and marketing through the winter months. In recent decades, development of potato production in an array of climatic zones has enabled year-round supply of fresh potatoes.

The fresh box trade

Since early settlement, consumers had difficulty obtaining fresh potatoes year- round. Fresh potatoes were available from November to May, with potatoes supplied from storages during winter and early spring.

Hand digging “new” potatoes, Limestone Coast, 1959. Early season “new” potatoes packed in wooden boxes to avoid skinning received a premium price. Source: PIRSA photo ID 105115.

Hand digging “new” potatoes, Limestone Coast, 1959. Early season “new” potatoes packed in wooden boxes to avoid skinning received a premium price. Source: PIRSA photo ID 105115.

In spring, consumers were anxious to buy fresh “new season” potatoes. These immature tubers skin easily and could not be marketed in hessian bags. Growers overcame the problem by hand digging and marketing these “new season” immature potatoes in wooden bushel cases to obtain premium prices.

Development of fresh washed prepacks

Washing and prepacking of potatoes commenced on the Northern Adelaide Plains in the 1960s. The Potato Marketing Act was modified in March 1964 to accommodate the legislative requirements for potato washing plants. Potatoes were washed and pre-packed into various “consumer friendly” size plastic bags, creating a more attractive product. This more attractive product reduced preparation time for consumers and offered labour savings for retailers.

Potatoes grown on sandy soils produce clean, bright, white, washed tubers for prepacks. Year-round supply was achieved by supplying winter potatoes from warmer low frost risk districts such as the Northern Adelaide Plains and along the River Murray. Crops planted in late summer matured in autumn and are stored “in field” for harvesting through the winter months.

Producing high quality prepacks presented technical challenges, including management of pathogens in the washing process, and cool storage to achieve good shelf life. Wider rotations for paddocks, soil pathogen testing, and improved seed quality reduced incidence of soil borne tuber disorders, vital for minimising skin blemishes and producing high tuber quality for premium pack out levels.

Improvements in computer technology through the 1990s enabled introduction of automated sorting, grading, and packing machinery that was more accurate and dramatically reduced packing shed labour requirements.

Over the past 30 years, several major potato packing companies have evolved into large vertically integrated “corporate” businesses. They operate numerous farms across different potato production regions, large packing operations, and distribution networks to Australia’s major wholesale markets and supermarkets.

Emergence of the processing potato industry

South Australian potato growers also developed supply of product to three processing sectors:

- Crisps for snack food products.

- French fry, roast potato, and other frozen potato products.

- Fresh processed potato food products (potato salad, diced product, fresh French fries).

Potato crisps

South Australia’s potato crisp industry developed in the 1950s and 1960s through establishment of several small manufacturers. Over the years, various amalgamations and business consolidations occurred.

Taste testing new crisping potato varieties, Adelaide, July 1973. Potential new varieties were run through a commercial crisp cooking process with the finished product being assessed by a tasting panel. Source: PIRSA photo ID 108198.

Smith’s Potato Crisps Ltd formed in the UK after WW1. They established a subsidiary in Australia in 1931. In August 1998, the Smith Snackfood Company Ltd was purchased by PepsiCo, and is now the main potato crisp manufacturer operating in South Australia.

Smith’s potato storage and processing plant was originally located at Kilkenny (near the Arndale shopping centre). In 1986, a new processing plant was built at the current South Road, Regency Park location. This facility has had numerous equipment upgrades over the years.

Through the 1960s and 1970s, potato variety trials conducted by PIRSA incorporated cooking tests and assessments for crisp manufacture. Support was also provided to the crisping industry in the 1970s with assessment of CIPC (chlorpropham) as a sprout inhibitor for stored tubers. CIPC mixed in a special oil formulation was fogged into potato storages using a PulsfogR model K1 machine imported from Germany.

The adoption of Atlantic as the main crisping potato variety eliminated the need for storage. Atlantic provided superior crisping qualities but had poor storage characteristics. This problem was overcome by supplying processing plants with Atlantic potatoes year-round from different production districts across Australia.

French fries and frozen potato products

Frozen French fry production emerged as a new potato industry sector in SA when local company Safries Pty Ltd established a processing facility near Penola in the 1980s. The SA Housing Trust built the initial factory, cool storage and freezer buildings which were leased to, and subsequently purchased by Safries Pty Ltd.

McCain Foods purchased the Safries business in 1992 and upgraded the Penola plant. McCain’s announced closure of this Penola facility from December 2013 to rationalise the efficiency of their Australian processing plants and gain improve competitiveness against imported frozen potato products. French fry, roast and other frozen potato products continue to be grown in the South East and are trucked to McCain’s larger manufacturing facility at Ballarat for processing.

PIRSA supported the South East processing potato industry with a comprehensive potato crop monitoring service between 1993 and 1998 (see Potato Crop Management Service section). This improved quality, yields and competitiveness of growers supplying the Penola and Ballarat French fry factories.

Fresh processed potato products

During the 1970s and 1980s, several small processors developed manufacturing of fresh French fries to supply fresh chips to “fish and chip” shops and caterers. Multinational take-away food chains have displaced most small “fish and chip” shops. Large take-away food retailers prefer the flexibility and labour savings of frozen French fries. Consequently, small manufacturing of fresh French fries has ceased.

The fresh processed potato food sector continues to produce potato salads and other fresh “meal ready” potato products. These are marketed to a wide range of supermarkets, restaurants, hotels, hospitals, and other institutions.

Seed potato production

The cooler climate South East potato district (around Mt Gambier, Kalangadoo, Penola and Coonawarra) had a lower incidence of aphids and virus. A small seed potato industry operated in this district from the late 1800s to the 1970s.

The location of a Horticultural Inspector at Mt Gambier (from January 1908) facilitated development of this seed potato production. The Horticultural Inspector checked paddocks and growing crops through the season to ensure they met seed crop standards. There were also minor areas of seed potato grown in the Mt Lofty Ranges.

As part of the drive to increase potato production during WW2, a formal South Australian seed potato certification scheme was first introduced in the 1940-41 season. It assessed 8 crops, with 4 crops passing certification and produced 32 t of seed. The number of seed crops being certified gradually expanded. A special category of certified seed was introduced in 1943 to encourage seed production during WW2 (assessed 34 crops producing 1,243 t in 1944)8.

From the mid-1950s, the number of South Australian seed potato growers declined as Victorian seed potato production districts gained a marketing advantage.

The SA seed potato certification scheme was administered by PIRSA, but the small number of seed potato growers made providing this service uneconomic. From 2004, arrangements were made for the Victorian Certified Seed Potato Authority (VicSPA) to provide seed potato certification services to SA seed potato growers.

Seed potato certification in South Australia, Victoria and New South Wales is now (2024) administered by the Australian Seed Potato Industry Certification Authority (AuSPICA) located in Toolangi, Victoria. It operates certification services in each major seed production district. Find further information about the role of AuSPICA.

Between the 1970s to the 1990s, tissue culture and mini tuber seed production techniques were developed, creating a revolution in the seed potato industry. This technology reduced the number of years potato seed crops had to be multiplied in the field, dramatically lowering field contamination with virus and soil borne pathogens, providing significant improvements in seed quality and delivers higher commercial crop yields.

Significant quantities of certified seed potatoes are now produced in the South East and Murray Mallee under the AuSPICA seed potato certification system. Expansion of certified seed production in South Australia has been partially driven by greater use of licensed varieties (and requirements for security of licensed varieties) obtained from overseas breeders under Plant Variety Rights licensing arrangements.

High quality seed production on Kangaroo Island

Developing isolated seed production areas to further reduce the incidence of virus and soil borne disease in “early generation” seed potato crops offered further yield and quality benefits. Kangaroo Island with its natural isolation was identified as an opportunity to produce elite potato seed.

Surveys involving soil and plant sampling of potential production areas showed that Kangaroo Island was free of significant soil borne diseases such as black dot, powdery scab, root knot nematode and pink rot.

In August 2000, Kangaroo Island was gazetted as a potato quarantine zone, the “Kangaroo Island Protected Production Area” (for Bacterial Wilt and Potato Cyst Nematode) under the Fruit and Plant Protection Act 1992. This introduced the following regulations:

- Ensure seed potatoes were only introduced onto Kangaroo Island as mini tubers or plantlets from accredited tissue culture laboratories.

- Apply protocols to minimise the risk of disease being introduced to Kangaroo Island on potato machinery or used containers.

- Require ware potatoes for consumption on Kangaroo Island to be washed and prepacked.

Kangaroo Island has become a specialist high quality seed potato producing zone using mini tubers as the initial parent material.

South Australian potato marketing legislation

During WW2, significant expansion of South Australia’s potato production to supply armed forces was fostered nationally by the Australian Potato Committee under national security regulations. It wanted to increase potato plantings by 50% in 1941-42 through the issue of production contracts with growers. SA potato plantings increased from 6,335 ac (2,565 ha) in 1942-43 to 9,105 ac (3,686 ha) (1,686 growers) in 1943-44, and 12,259 ac (4,963 ha) (1,815 growers) in 1944-459.

During WW2, inspection, and acceptance of potatoes from contracted growers on behalf of the Commonwealth Potato Controller was done by PIRSA horticultural inspectors based at Mile End and Mt Gambier. This process continued until the 1947-48 season. The roller inspection tables used at Mile End and Mt Gambier were retained by the PIRSA and subsequently upgraded in 1963.

Contracted marketing of potatoes ceased in 1948, resulting in market oversupply and poor returns for the many small growers. Following lobbying from growers, potato marketing boards were established in most Australian states. In December 1948, South Australia’s Potato Marketing Act 1948 was enacted following a poll of potato growers. By late 1956, potato marketing boards only remained in South Australia, Western Australia, and Tasmania.

The Potato Marketing Act 1948 provided for establishment of the South Australian Potato Board. The Board of nine members, comprised five growers and two merchant representatives elected from registered growers and merchants. The Chairman and a retailer/consumer representative were recommended by the Minister of Agriculture.

The Potato Marketing Act gave the SA Potato Board powers to:

- Register growers

- License merchants

- Market potatoes grown in South Australia. Potatoes grown in South Australia but sold outside of the state were not subject to control of the Board

- Fix the quantities of potatoes or proportion of a grower’s crop that could be marketed at any time

- Fix maximum and minimum prices for potatoes (taking account of grade, quality, quantity, and other circumstances), and terms and conditions under which they may be sold, including a maximum retail margin

- Administer the fining of people (summarily) who fail to comply with the Act

- Arrange polls of growers and merchants to decide whether the Act should continue.

Whilst this legislation gave South Australia more stable production levels, retail prices, and created more income stability for growers, it did not encourage growers to grow a high-quality product or produce crops more efficiently.

The SA Potato Board purchased premises at Kent Town where its offices and inspection facility were based. Its staff collected monthly information about the quantity of potatoes planted along with expected production and demand. The Board also ran regular consumer promotion programs. Crop and marketing information was provided to growers, packers and merchants via regular regional meetings and newsletters. Growers found this information valuable for planning production and scheduling marketing.

The emergence of the potato washing and packing sector required an amendment to the Potato Marketing Act 1948 to incorporate a definition for licensing of “potato washers”. This amendment was made in March 1964 and functions of the Board were updated as part of this amendment. A further amendment passed in October 1973 strengthened fines and documentation requirements.

Potato promotion at a Mt Gambier supermarket – June 1975. The SA Potato Board ran regular promotion programs (using the Sammy Spud character) with consumers to increase consumption and sales. Source: State Library of SA Image BRG 347/1715

Following complaints about irregularities in operation of the SA Potato Board, the Ombudsman undertook an investigation and tabled a report in January 1984. South- East potato growers had long complained that the Potato Marketing Act was an impediment to their competitive operation.

The Ombudsman’s report was followed by a more comprehensive investigation into the role of the SA Potato Board and its supporting legislation. This review was by a Working Party chaired by Mr G.D. Webber (Chief Regional Officer, Central Region, PIRSA) with membership comprising grower representatives, the Potato Board’s Manager, and Mr Ian Lewis a PIRSA Horticultural Marketing Officer. Formed in June 1984, the Working Party received 44 public submissions and tabled its final report in March 198510. This final report recorded a 5:3 vote of the Working Party in favour of retaining the Potato Marketing Act.

Following tabling of this report, the SA Government decided to repeal the Act in June 1985. Subsequently provisions were made for redeployment or retrenchment of staff and settling of assets and liabilities.

South Australia’s Potato Industry Trust

Following wind up of the SA Potato Board, residual assets after settling all its liabilities were transferred to a trust fund. A trust fund was established in 1987 to administer the investment of these residual funds and use income from these assets for various potato industry development activities and projects.

The initial Potato Industry Trust Fund had a chairman appointed by the Minister of Agriculture, potato industry trustees, and was administered by PIRSA with funds being invested in secure Government interest bearing deposits (mainly through the SA Financing Authority).

In 1996-97, a new Trust Deed Agreement between the Minister of Agriculture and the potato industry was developed to manage the then $1.52m of assets. This new agreement updated operation of the trust, enabling use of a wider range of investment options, and moved management of the trust to industry via appointing 3 grower trustees and a fourth trustee representing the Minister of Agriculture. The updated Trust Deed Agreement required development of a 3 yearly Strategic Plan to guide investment of trust income in industry projects.

A further update of the Potato Industry Trust agreement occurred in 2008-09 with appointment of new trustees. A new levy collection mechanism was also introduced for the SA potato industry using the Primary Industries Funding Scheme Act 2005.

South Australia’s Potato Industry Trust continues to operate. Find further information about its Board, operations, funds application process, and major projects for SAPIT.

Major research and extension programs

The South Australian Government has a long history of supplying research and extension programs to the state’s potato industry with the objective of growing industry productivity, profitability, and the State’s economy. Extension services were provided regionally via the agency’s network of district horticultural advisers.

Information services were provided through numerous workshops, field days, conference presentations, as well as a comprehensive array of Journal of Agriculture articles, leaflets, fact sheets and publications. For more information about these sources go to the “Publications and Further Reading” section at the end of the document.

Earliest records of potato research date back to 1909. Mt Gambier branch of the SA Agricultural Bureau requested a series of experiments on “efficacy of phosphatic, potassic, and nitrogenous manures singly and in combination” and seed sources on productivity. Potato fertiliser experiments at Mt Barker were also reported in the July and August 1909 edition of the SA Journal of Agriculture.

Other early research projects included importation of new potato varieties in 190911 and seed potato trials conducted at Bridgewater and Blackwood in 1910-11 that compared open stored vs covered seed potatoes for 8 varieties.

Pest and disease programs

PIRSA and SARDI horticulture pathologists and entomologists have provided South Australia’s potato industry with comprehensive pest and disease identification and advice services over many decades. Following are some highlights of major pest and disease research and management programs provided to South Australia’s potato industry:

Late blight

Late (Irish) Blight (Phytophthora infestans) appeared almost simultaneously in many regions of Australia in 1909. This caused much consternation, with a conference of state Ministers of Agriculture being held in Melbourne in August 190912. Late Blight was subsequently discovered in several South East potato crops in the 1910-11 season.

To curb spread of this very debilitating disease, restrictions were placed on movement of potatoes. Amendments to the Vine, Fruit and Plant Protection Act 1885 were proclaimed on 23 November 1911 preventing removal of potatoes from the Hundreds of MacDonnell, Robe, and Grey to other parts of the state. Controls were administered by Mr Rodney Fowler, Inspector of Orchards in the South East. Despite these measures, Late Blight was discovered across many potato crops in the Mt Lofty Ranges in 1912.

Demonstrations using copper fungicides to control Late Blight were set up in 1911-12 using a Fleming type of potato sprayer at the garden of Mr George Packer at Athelstone with “gratifying results”. Mr Packer was so impressed he bought the spraying machine after the trials were completed. A similar demonstration of Bordeaux and Burgundy copper sprays was set up by Horticulture Inspector Fowler in 4 large potato fields at Mt Gambier using a Doncaster sprayer. These treatments improved yields dramatically. The success of these trials was widely reported in newspapers across Australia at the time13.

Late Blight outbreaks were an ongoing problem in high rainfall seasons over the next 5 years until copper sprays became a regular treatment. With these outbreaks of Late Blight, Western Australia introduced stringent controls preventing SA potatoes entering their state, greatly reducing this export trade.

Tuber moth

Potato tuber moth was a major pest because of its burrowing damage to tubers, especially in hot dry seasons. Switching from furrow irrigation to overhead sprinklers significantly reduced its incidence. The introduction chemical pest control began in the 1940s, but pest resistance became a problem. Integrated pest management systems developed in the 1990s, resulted in potato tuber moth becoming a minor problem.

Nematodes

Nematologists Graham Stirling and later Greg Walker completed nematode soil surveys across South Australia’s potato growing districts over several decades. These identified the presence of root knot nematodes in some districts and confirmed that South Australia was free of Potato Cyst Nematode (PCN).

Outbreaks of Golden Potato Cyst Nematode (PCN) (Globodera rostochiensis) were discovered in Western Australia in 1986 (later eradicated), and Victoria commencing in 1991. This serious soil borne parasite can inflict large potato crop losses, cysts can persist in soils for 20-30 years, and it creates significant barriers for export trade. To date, the second main species, white or pale PCN (Globodera pallida) has not been discovered in Australia14.

As part of the national strategy for managing PCN, PIRSA and SARDI staff were involved in potato crop inspections across South Australia to confirm state freedom. Development of a national PCN plan followed, incorporating consultation with potato growers in all major production regions. A final version of the PCN National Management Plan was published in May 201115.

Bacterial wilt

The soil and seed borne disease bacterial wilt became a significant problem in several districts during the 1990s due to movement of poor quality infected seed. This impacted sales of potatoes to Western Australia, requiring introduction of 20 km quarantine zones around bacterial wilt outbreaks, and use of a range of other treatments and procedures. Bacterial Wilt is now controlled using quarantine strategies and planting disease free seed.

Integrated pest management

In 1992, Dr Helen Dillard, an extension pathologist from Cornell University conducted a major review of strategies for reducing pesticide use in the SA potato industry. This survey identified that rhizoctonia and target spot continued to be the main disease concerns for growers. A major outcome from this study was the accelerated adoption of integrated pest management (IPM) for pest control across SA’s potato industry. Much of this IPM technology was sourced from programs developed by the Victorian Department of Agriculture16.

Potato industry field day, Woodside, February 1973. These district field days provided comprehensive information about new varieties, irrigation, nutrition, pest and disease management and other technology to potato growers. Source: PIRSA photo ID 104560.

Recent potato disease research

From 2000, SARDI’s horticulture pathology team (comprising Dr Trevor Wicks, Barbara Hall, Robin Harding, and several other staff) completed a broad array of national potato disease trials to produce comprehensive management strategies for the following key diseases:

- Bacterial (soft rots) breakdown in washed potatoes caused by three species of Erwinia (now classified as Pectobacteriums), and strategies for managing this significant disease in washing plants.

- Black Dot (Colletotrichum coccodes), a significant soil borne disease that gives tuber blemishes. Control strategies were developed for seed and washed potato crops.

- Potato Early Dying, a soil borne disease complex caused by a combination of root lesion nematodes (Pratylenchus spp.) and the fungus Verticillium dahlia.

- Pink Rot (Phytophthora erythroseptica) a s tuber rotting disorder on poorly drained soils.

- Rhizoctonia or black scurf (Rhizoctonia solani), a common “cosmetic” tuber disease causing significant downgrading of washed potatoes.

- Incidence of soil borne diseases on seed potatoes.

- SARDI also provides a virus testing service (using leaf or tuber samples) for the potato viruses PLRV, TSWV, PVX, PVY, and PVS. This service supports the AuSPICA seed certification process.

Molecular diagnostics for potato diseases

SARDI developed a national potato soil disease diagnostic and risk assessment service in collaboration with the Tasmanian Institute of Agriculture and Department of Environment and Primary Industries Victoria. Launched in August 2013, this service is known as Predicta Pt.

The Predicta Pt service is based at SARDI’s Molecular Diagnostic Centre at the Waite Institute and uses DNA testing to assess the population densities for a wide range of potato pathogens and nematodes in soils, plants, and seed potatoes.

SARDI was awarded the John Deere Productivity Partner Award at the AUSVEG Awards for Excellence in June 2014. Kathy Ophel Keller along with the collaborative team were also awarded the Bayer Crop Science Researcher at the 2013 Ausveg Awards for development of the Predicta Pt service. Michael Rettke was also instrumental in assembling a wide range of potato pathology science to develop elements of the Predicta Pt soil borne disease diagnostic tool.

Data provided from the Predicta Pt testing service is widely used by growers to determine disease risks in individual paddocks, to guide management strategies, or make variety choices to minimise losses. Predicta Pt provides testing for a wide range of potato pathogens plus training and manuals to aid agronomists servicing Australia’s potato growers.

Predicta Pt is especially important for the seed potato industry and is often used to establish the presence of pathogens in soils before planting. Soil testing for Potato Cyst Nematode (PCN) is carried out for all certified seed lots. Plant tissue testing for potato viruses is used for seed crops as a formal part of the national seed potato certification service.

AuSPICA, the Australian Seed Potato Industry Certification Authority provides independent certification services to seed potato growers in Victoria, South Australia and northern New South Wales. Learn more about the seed certification services and standards by AuSPICA.

More detailed information about the Predicta Pt testing service for potatoes, including its range of pathogens can be obtained from the SARDI publication “Testing for Seedborne and Soilborne Pathogens – Potatoes”, or the SARDI's molecular diagnostics.

Potato crop nutrition

Since its inception, PIRSA has supported the South Australian potato industry with various potato fertilizer research trials and information. These commenced in 1909 with phosphorus and potassium fertilizer trials in the South East. Further trials applying nitrogen fertilizers via sprinkler systems were run in the 1950s.

However, the most significant series of fertilizer experiments were done by SARDI Horticultural Research Officers Norbert Maier and Dr Chris Williams over 20 years commencing in 1982. These trials were initiated because of widespread problems with after cooking flesh darkening, other quality issues, and variable yields.

These potato nutrition experiments evaluated:

- The effects of nitrogen, phosphorus, and potassium rates on yield, specific gravity, crisp colour, and tuber chemical composition. These experiments included comprehensive cooking tests to verify tuber quality improvements.

- Effects of nitrogen, phosphorus, and potassium application rates on petiole sap nutrient concentrations across the main potato cultivars being grown.

- Development of new rapid “in field” petiole sap testing techniques.

- Assessed the impact of potassium and phosphorus fertilizers on the uptake of cadmium by potato tubers.

This comprehensive nutrition research was significant nationally, developing potato yield and quality response curves for application of nitrogen, phosphorus, and potassium. These response curves allow soil and sap nutrient tests to be used to optimise yield, tuber quality, economise of fertilizer applications, and minimise environmental pollution from excessive use of fertilizers.

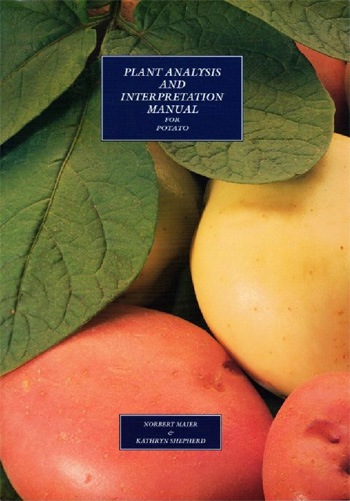

The SARDI handbook “Plant Analysis and Interpretation Manual for Potato” prepared by Norbert Maier and Kathryn Shepherd in 1998. It assembled the best national and international plant analysis data for use by Australian potato agronomists. It was supported by a decision support software CD to assist potato agronomists with interpreting potato tissue analysis data.

The huge array of potato nutrition data sourced from research in Australia, the USA, Canada, and several other countries was summarised and assembled by Norbert Maier and Kathryn Shepherd in 1998. It was published as a handbook entitled “Plant Analysis and Interpretation Manual for Potato”. This significant national document contains comprehensive information about:

- Key steps in using plant analysis with potato crops including sampling techniques, laboratory analysis techniques, and interpretation of plant test data.

- Tissue analysis values (for various parts of potato plants by potato variety) for essential plant nutrients: nitrogen/nitrate, phosphorus, potassium, calcium, magnesium, sodium, chloride, sulphur, boron, copper, zinc, manganese, and iron.

- Deficiency symptoms for various essential nutrients for growth of potatoes.

- A comprehensive bibliography of papers and references applicable to each section of the handbook.

The handbook was also supported by a decision support software CD titled “Crop Test – Potato Crop Nutrient Evaluation System”. This software tool designed to be used by agronomists and potato crop managers contained:

- Keys for identifying symptoms of plant nutrient stress.

- Information about deficiency and toxicity symptoms, including a large array of photographs of plant nutrient deficiency symptoms.

- Interprets petiole and leaf test results for a wide range of potato cultivars (from deficient to excess nutrient levels).

- Charts plant nutrient data during the growing season and enables presentation of multiple charts for crop performance comparison.

- Provides a comprehensive information database and bibliography for each nutrient.

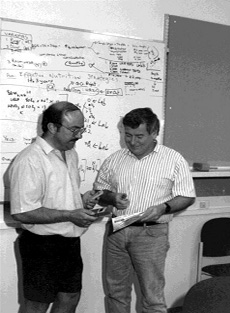

Development of an on-farm sap nitrate test

Correct management of nitrogen (N) is essential since excess or deficiency may reduce potato yield and/or quality or may lead to pollution in runoff water. Dr Chris Williams in collaboration with Norbert Maier calibrated a rapid sap nitrate test for potatoes at different crop growth stages (based on the length of a plant’s longest tuber).

This was developed into a field kit form and commercialised as the Nitraquik test kit for on farm use in 1991. The Nitraquik nitrate test kit could provide potato growers or agronomists with “in field” information about N applications needed. It enabled savings on fertilizer costs while optimising yield and avoiding excessive nitrogen applications.

Soil and land management

Potato and vegetable growers were identified as significant contributors to water pollution in the Mt Lofty Ranges water catchment area, an important supplier of water to the city of Adelaide. In 1989-90, the Mt Lofty Ranges Land Management Project (managed by Greg Cock) was established. This project demonstrated and encouraged the adoption of conservation techniques such as rapid establishment of cover crops after harvest, modified tillage to reduce organic matter loss, and better nutrient application techniques. The program was applied across 6,000 ha of potato and vegetable growing land in the Mt Lofty Ranges.

During the 1990s potato and vegetable industries in the Mt Lofty Ranges were in decline being displaced by wine grape and other perennial tree crops. These perennial crops use minimal tillage and low nitrogen applications, greatly reducing soil and nutrients in runoff, and the risk of reservoir contamination.

There were also problems with soil erosion in the Mallee and Riverland under centre pivot irrigators in the fallow years between potato crops. A project funded by the South Australian Murray Darling Basin NRM Board and delivered by Dr Ben Thomas (Scholefield Robinson Consulting) and Geoff Thomas (Thomas Project Services) identified the issues and a range of solutions, documented in “Guidelines for Management of Land Associated with Centre Pivots” published in 200817.

Heavy metals in potatoes

During the mid-1990s, crop residue testing revealed that some Australian potato crops had cadmium (a heavy metal) levels close to the maximum permitted residue level. Adelaide based, CSIRO Soils Division, researcher Dr Mike McLaughlin ran a national research program to evaluate the cause (with support from SARDI researchers Norbert Maier and Dr Chris Williams).

This revealed that elevated irrigation water salinity caused greater absorption of cadmium. The choice of potato cultivar also had moderate effects. An extension program encouraged grower adoption of irrigation strategies (especially where saline irrigation water was being used) to minimise cadmium uptake and residues.

Herbicides and weed control

Traditionally potato growers used mechanical methods of weed control, involving harrowing at emergence, followed by inter row cultivation and banking or hilling. This removed weeds in the inter row space and buried young weeds along the plant row. The advent of tractors with 3 point-linkage (from the 1940s) made this mechanical control of weeds easier and more accurate.

Growers obtained an additional weed control tool with the release of the post emergent herbicide metribuzin (commonly marketed by Bayer as SencorR) in the late 1960s. Applied to young potato crops, this herbicide greatly improved grass and broadleaf weed control, and reduced reliance on mechanical weed control techniques.

Further farm trials to identify the metribuzin tolerances of new potato cultivars were conducted by Dr Chris Williams of SARDI with Dave Riches of Bayer Aust Ltd from 1996 to 2000. This revealed that the new red skinned cultivar Bison, was highly sensitive to metribuzin while the major crisp cultivar Atlantic and red skin Pontiac (fresh market) were moderately sensitive at label rates. This research led to Bayer modifying registered label rates of metribuzin in Australia. Matching funding for this project was provided by Bayer Aust. Ltd and Horticulture Research & Development Corporation (HRDC).

New variety assessment and introduction

The first new potato variety assessment project occurred in 1909. Twelve varieties imported from the UK for this program included Early Regent, Duke of York, May Queen, Ruby Queen, Klondyke, Royal Kidney, British Queen, Ninetyfold, Up to Date, Challenge, Discovery, and Queen of the Veldt18.

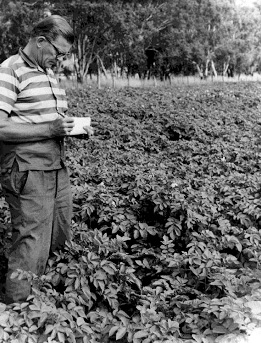

Inspecting a potato variety trial, Adelaide Hills February 1973 – part of the regular field day program. Source: PIRSA photo ID 104759.

Post WW2, the Victorian Department of Agriculture established a potato breeding program at Toolangi Research Centre. Through the 1960s and 1970s, Henry Feddersen planted new Victorian variety selections in assessment and demonstration trials across SA potato districts. This included yellow fleshed varieties commonly grown in Europe but new to Australia.

In the 1990s Australia’s potato breeding and variety program was upgraded to become the National Potato Improvement and Evaluation Scheme (NaPIES). It was funded in part by a potato Industry levy of $1/t and matched with Federal funds through the Horticulture Research and Development Corporation. Promising new breeding selections and imported varieties were distributed to each state for assessment in the main potato growing districts. Dr Chris Williams coordinated the NaPIES trials in SA from 1982 to 2002.

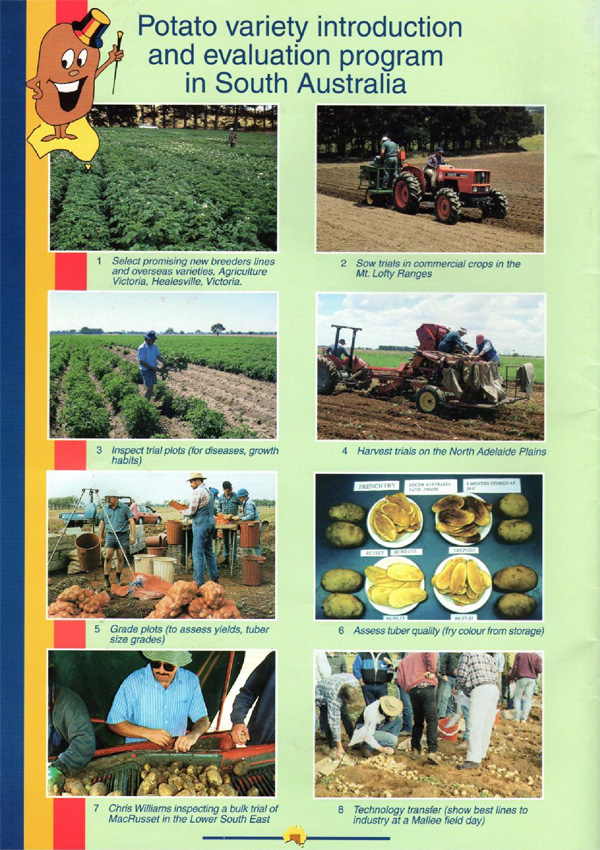

Steps in the SA potato cultivar evaluation program – 1997. Source: Potato Varieties for South Australia – guide to performance and selection by Dr Chris Williams et al; published by PIRSA 1997.

NaPIES released several commercial cultivars. Of special interest to SA potato growers were new washing/prepacking and processing varieties, including:

- Onka – a potential replacement for Kennebec in the mid 1970s and release of the major washed cultivar, Coliban in 1972

- Selections of Atlantic and Denali (major crisp varieties), Russet Burbank (major French fry variety), and Shepody.

- 1988-89 – Crystal and Bison.

- 1991-92 – Wilwash and Winlock.

- 1993-2002 – Desiree, Snow Gem, Nadine, and Ruby Lou.

After many years of investment in the NaPIES program, the Australian potato industry and DPI Victoria commenced an exit strategy in 2011.

Introduction of Australia’s Plant Breeders Right Act 1994 encouraged leading potato processors (both crisping and French fries), and many fresh potato packers to begin establishing relationships with overseas potato breeding schemes. Exclusive company to company relationships were formed, with agreements for access to specific varieties, and development of promotion and marketing opportunities for growers licensed to use these varieties.

Potato breeders in the USA, NZ, Scotland, and various European countries have supplied proprietary varieties. These are introduced to Australia as tissue culture material through the AQIS quarantine service, and post-quarantine are considered for protection under the Plant Breeders Rights Act 1994, then released under licensing agreements.

Plant breeder’s rights have enabled Australian potato marketers to gain exclusive rights from overseas breeders to produce and market numerous new varieties, including some with special dietary characteristics. The outcome has been a much wider range of new potato varieties for consumers to choose from.

Demonstrating record tuber yields

In 1991-92, SA on farm variety demonstration trials with the aim of exceeding tuber yields of 100t/ha. These world leading yields were achieved at a time when Australia’s potato growers were expecting commercial yields of 19 to 44 t/ha.

Dr Chris Williams working with experienced Mt Lofty Ranges potato grower Mr Ron Wenzel. Trial plots in his commercial crop achieved tuber yields of over 100t/ha (of No 1 grade tubers 80-450 grams) for the cultivars; Winlock, Kennebec, Patrones and Wilstore. These world leading yields were obtained using high quality seed, calibrated soil, and plant tests to optimise plant nutrition, well managed irrigation, and maintaining a fully functional, healthy, closed crop canopy for about 95 days after the start of tuber initiation.

Key personnel

Since its establishment in 1902, PIRSA and SARDI have provided a wide range of services to the SA potato industry. Prior to WW2, this was via a network of district inspectors and instructors or advisers.

Post WW2, District Horticultural Advisers continued their important role of delivering information and technology to potato growers. However, the introduction of potato research officers from 1949 enabled development of more specialised technical information.

With the gradual reduction of Government funded extension services from 2005 onwards, there has been a transition to delivering technical information to growers by commercial consultants and potato agronomists. South Australia’s potato growers are now serviced by a range of commercial potato crop consultants.

Below are some details about key PIRSA and SARDI staff servicing the SA potato industry, and their major achievements:

Pre-WW2 activities

Pre-WW2 activities

From 1908 through to 1920, SA’s horticulture districts were serviced by District Orchard Inspectors who gradually developed an advisory role. In 1920, these inspectors were formally endorsed to become Orchard Instructors. Up until WW2, the South East was SA’s main potato growing district, and its Orchard Inspectors and Instructors were the main PIRSA officers serving SA’s potato industry. This included:

- 1908 to 1920 – Mr Rodney Fowler – he moved on to become the Manager of the Blackwood Experimental Orchard in 1920

- 1920 to 1922 - Mr J.B. Harris

- 1922 to 1934 - Mr H.H. Orchard

- 1934 to 1939 - Mr A.L. Warren.

Some of the major projects and issues dealt with by these Orchard Inspectors and Instructors were:

- Outbreaks of Late/Irish Blight and subsequent quarantine measures from 1911, then introduction of copper fungicides.

- Introduction of Sale of Fruit Act 1915 grade standards which were upgraded in 1928 and replaced in 1935 by the Fruit and Vegetable Grading Act 1934.

- 5 acres (2 ha) of variety and fertilizer experiments at Moorak on the property of A A Klisby from 1915 to 1923. There were also other fertilizer experiments at Rendelsham, Penola, and Mt Gambier (Pope Bros 1916).

- Potato crop competitions at Mt Gambier were inaugurated by Horticultural Inspector H H Orchard and operated from 1928 to 193419. They encouraged the use of high-quality seed. Potato crop competitions were re-established after WW2 and run by H D Feddersen through until the mid-1970s.

Presenting a cup to Mr Ron Telfer of Glencoe for his superior potatoes, July 1964. L-R: Robert “Bob” Beck, Greg Botting (District Horticulture Adviser), Gilbert “Gill” Myer and Ronald “Ron” Telfer. Potato crop competitions ran from the 1928 to the 1980’s. Crop competitions were important for encouraging growers to adopt new production technology. Source: State Library of SA Image BRG 347/1759.

Post-WW2 potato specialists

Post-WW2 potato specialists

Gordon Edwards

In January 1949, Gordon Edwards was appointed as the first vegetable Horticultural Research Officers. Since potatoes were the main vegetable crop, approximately half of his time was spent working with the potato industry. Some of the key potato industry programs initiated by Gordon Edwards through the 1950s included:

- Encouraging mechanisation in the potato industry to overcome post WW2 farm labour shortages (introduction of harvesters and bulk handling).

- Demonstration of post planting applications of nitrogen by applying urea through sprinkler systems on the Northern Adelaide Plains.

- An ongoing series of potato crop competitions in the Adelaide Hills with associated field days.

- Rhizoctonia and aphid control trials.

- Assessment of systemic insecticides and early top killing to reduce leaf roll virus infections.

- Warning services for autumn Late/Irish Blight infections.

- Fostering development of potato production on the Northern Adelaide Plains.

Henry Feddersen

With the growing significance of the potato industry, Heinrich (Henry) Distel-Feddersen was appointed as the first specialist Potato Adviser in September 1959. He immigrated to Australia from Germany after WW2 and continued in this research and extension role until 1981.

Some of the key technologies and activities fostered by Henry Feddersen included introduction and evaluation of:

- New fresh and crisping potato varieties sourced from the national breeding program at Toolangi, Victoria. This resulted in the release of Onka and European yellow fleshed varieties.

- Demonstration of seed pre-cutting techniques (1965)

- Improving potato plant nutrition through post emergent fertilizer trials at Virginia and the Mt Lofty Ranges.

- Assessment of maleic hydrazide and CIPC to delay tuber sprouting in storage. This included importation of a Pulsfog type K1 fogging machine (1972) for treatment of potatoes in storages.

- Developing cool night air potato storages (based in a large shed on the property of R A Nitschke at Littlehampton) between 1967 and 1972 to improve the out-turn of stored potatoes. This work was done in conjunction with Post Harvest Researcher Barry Tugwell and with support from USA based potato storage specialist Dr Walter Sparks from the University of Idaho, Aberdeen Research and Extension Centre.

- Herbicides for weed control in potato crops.

- Crop competitions for improving productivity with an emphasis on profitability.

- Improving control of target spot and other leaf diseases.

- Trapping, monitoring, and providing seasonal warnings about aphid flights. This information was used by growers to minimise leaf roll virus in ware and seed crops on the Adelaide Plains and in the Mt Lofty Ranges.

Henry Feddersen assessing potato variety trial, Woodside, February 1973. He was also active in the German community, being President of the SA German Club. In December 1982, he was awarded an MBE for services to the migrant community and German Australian relationships. Source: PIRSA photo ID 108210.

Dr Chris Williams

During his period as Senior Research Officer – Potatoes from 1982 to 2006, Dr Chris Williams delivered a range of research projects to support the SA and Australian potato industry.

Major potato projects included:

- Evaluation of new breeding lines and cultivars (fresh, crisping, and French fry cultivars) across potato production districts.

- Calibration of simple on farm petiole sap nitrate tests for assessing the nitrogen status of potato crops. Work based on his research was published in 2 papers in the Journal of Plant Nutrition 1990.

- Assessing tolerance of various potato cultivars to the herbicide metribuzin.

- Marketing and production of yellow fleshed potato cultivars.

- Presentation of a national paper on using soil and plant tissue tests for potatoes at the national potato industry conference in Warragul, Victoria in 1990 (co-authored with Norbert Maier). This was awarded best presentation at the conference based on value to the potato industry.

- Natural products for the control of potato tuber seed piece decay. This produced an 8-page laminated guide folder titled: “Make more money by correct handling of potato seed tubers”, by Drs Williams and Wicks was sent to every potato enterprise in Australia in 1993.

- Using improved cultivars and management systems to achieve 100 t/ha crops.

- Convenor of ‘Potatoes 2000 – linking research to practice’, a very successful national potato research and technology transfer conference, held in Adelaide, attended by over 300 delegates from Australia and overseas. Dr Chris Williams and Leigh Walters were the editors of the (283 page) proceedings.

Since Dr Williams’ retirement in 2009, PIRSA/SARDI has not appointed another dedicated potato research officer.

Dr Chris Williams, Senior Research Officer, Potatoes (left) demonstrates new Nitraquik nitrate sap testing meter to Barry Philp, Regional Officer, Central Region, 1990. Development of rapid nitrate sap testing was part of a national program to improve potato crop nutrition management. Source: PIRSA photo ID 104820.

Norbert Maier

Norbert Maier in his role as the SARDI Senior Horticultural Research Officer completed a wide range of research projects with potatoes and vegetable crops. Of national significance was a major potato nutrition program between 1980 and 2000, comprising:

- Calibration of soil and plants tests for potassium nutrition of potatoes for optimum yield and quality.

- Comparison of phosphorus fertilizers and their impact on the soluble phosphorus concentration in petioles.

- Effects of nitrogen, phosphorus and potassium on potato yield and petiole nutrient concentrations.

- Effects of nitrogen, phosphorus and potassium on yield, specific gravity and crisp colour and tuber chemical composition (including reducing sugar concentration) of potatoes.

- Development of interpretation standards for assessing the nutrient status of irrigated potato crops.

The outcomes from this work were documented in the “Plant Analysis and Interpretation Manual for Potato” handbook (see the Potato Crop Nutrition section).

Mark Heap – Potato Crop Management Service, South East

South East Horticulture Adviser, Mark Heap, with support from other staff, established a specialist Potato Crop Management Service (PCMS) for frozen French fry potato growers in the South East. The business plan for this service was developed as part of the South Australian Enterprise Workshop in 1992 and won the F.H. Faulding award for Commercial Development. The development team for the business plan comprised Barry Philp, Mark Heap, Venton Cook, Brad Smith and Shaun Whitworth.

PCMS was a joint venture involving PIRSA, Mc Cain’s Foods, South East Potato Growers Association and the Horticultural Research and Development Corporation (HRDC). This project combined the best available technical information into a holistic crop management system delivered by several field officers (including Derek Cameron). It commenced in July 1993 and incorporated the following modules:

- pre plant checking of soil borne pests and diseases.

- soil nutrient testing to recommend pre plant fertilizers.

- regular petiole analysis to recommend nutrient applications during the growing season.

- assessment of irrigation system performance, and scheduling of irrigation based on crop evapotranspiration and growth stage water requirements.

- crop scouting and monitoring to identify pest and disease outbreaks and to recommend control measures.

- in field crop maturity and quality testing to assist harvest decision making for processing.

- developed new easy to understand ways of presenting graphic crop monitoring data to growers.

At its height, this service monitored 1,100 ha or about 50% of potato crops grown in the South East. The PCMS was delivered by PIRSA over 4 years, and significantly improved the competitiveness of South East potato growers. Following demand from commercial agribusinesses servicing growers, a package of the systems and technology was provided to fertiliser and chemical resellers (mainly IAMA resellers) servicing South East potato growers.

Following completion of the project, some staff delivering services went on to provide commercial crop monitoring services (eg Derek Cameron) to South Australian potato growers.

Barry Philp

Barry Philp grew up on a potato and vegetable growing property, and after completing a tertiary qualification in Agriculture, commenced work as a PIRSA Technical Officer supporting the Research Officer – Potatoes with delivery of research programs between 1973 and 1976. From 1981 to 1989, he worked as a Horticulture Adviser on the Northern Adelaide Plains providing industry development programs to potato and other vegetable industries.

During the 1990s, Barry Philp was a regular participant at national industry activities including AUSVEG Potato Section meetings, as one of two national technical advisers to the Australian Potato Industry Council, and contributed to a sub-committee developing management strategies for Potato Cyst Nematode in Australia. He was also the Minister of Agriculture’s representative on the SA Potato Industry Trust Fund between 1996 and 2008.

Following an overseas visit to potato growing regions in the USA in 1998, Barry Philp initiated a national project to develop electronic information systems for the Australia potato industry. This led to a three-year HRDC funded project delivered by Leigh Walters that fostered adoption of electronic and internet-based information services to the Australian potato industry.

Barry Philp speaking at the official opening of PIRSA’s Lenswood Horticultural Centre new office and laboratory complex extensions – March 1992.

Potato research technical officers

Potato Research Officers were supported by Potato Technical Officers to assist with preparation and operation of field trails, planting, harvesting, recording crop observations, development of machinery, and collation of trial data. These Technical Officers had previously been commercial potato growers, so had considerable practical experience.

Ron Nitschke assisted Henry Feddersen between 1970 and 1975. Ross Allen then held this position between 1975 and 1992, supporting Henry Feddersen, Dr Chris Williams, and Norbert Maier. During peak planting and harvest periods between 1973 and 1976, assistance was also provided by Technical Officer - Vegetables, Barry Philp.

Trial and research machinery

With major “on farm” variety and fertilizer testing programs operating across the state, specialist planting and harvesting machinery was essential to improve the accuracy of experimental work, replicate techniques used by commercial potato growers, and reduce labour needed for planting trials.

The first potato trial planting machine was built in 1969. Transported on a custom trailer, this planter could be towed to grower properties using a conventional vehicle. It incorporated trays to hold predetermined sequences of seed and used a fertilizer delivery belt for application of premixed and weighed quantities of fertilizer along standard plots. It used a gearbox from a cereal seed drill to vary planting distances and plot length.

First potato trial planter in use at Littlehampton, October 1969. Adjustments enabled variable plant and row spacings, plot length and fertiliser rates. Seed trays were used for variety trials. Source: PIRSA photo ID No 104772.

A new 3 point-linkage tractor mounted planter was built at Lenswood Horticultural Centre (by Mervin Schubert and Ross Allen) in 1991. This machine was lighter, more compact, manoeuvrable, and easier to transport. It utilised two cone heads for fertiliser distribution (adapted from units used on cereal trial planters). The greater planting accuracy and flexibility was particularly important for the large number of fertilizer and micronutrient trials conducted in the 1990s.

The second trial potato planter built at Lenswood Research Centre by Mervin Schubert (left) and Ross Allen (right) in 1991. Using 3 point linkage mounting, it was more compact and featured twin cone fertilizer distribution heads, critical for planting trials requiring very accurate fertilizer and soil additive applications. Source: PIRSA Photo ID 108696.

The second trial potato planter built at Lenswood Research Centre by Mervin Schubert (left) and Ross Allen (right) in 1991. Using 3 point linkage mounting, it was more compact and featured twin cone fertilizer distribution heads, critical for planting trials requiring very accurate fertilizer and soil additive applications. Source: PIRSA Photo ID 108696.

A specialist potato trial harvester was custom built in 1973-74 by Echunga Sales and Service with support from Vegetable Technical Officer, Barry Philp. It used the base frame, lift chain and trash rollers from a Port Major potato harvester. The rear of this machine was customised using an extended adjustable slope sorting belt and bagging gates for harvesting of small plots and enabling size grading tubers while harvesting. It also had a wide operator platform to carry harvested bags of tubers. This harvester was trucked to grower properties for harvesting of trials.

The potato research machinery was stored and maintained at Lenswood Horticulture Centre.

Customised potato harvester for trial plots at Woodside 1974. Machine was built by Echunga Sales and Service with support from Barry Philp in 1973-74. It incorporated an adjustable slope sorting belt for size grading tubers as each plot was harvested. Source: PIRSA Photo ID 415702

Customised potato harvester for trial plots at Woodside 1974. Machine was built by Echunga Sales and Service with support from Barry Philp in 1973-74. It incorporated an adjustable slope sorting belt for size grading tubers as each plot was harvested. Source: PIRSA Photo ID 415702

References

References

1 Australian Bureau of Statistics; Agricultural Commodities Australia 2021-22; courtesy Peter Philp, Philp Hort Consultants; 2022.

2 Australian Bureau of Statistics 71240DO001_201011 Historical Selected Agricultural Commodities, by State (1861 to Present), 2011.

3 Australian Horticulture Statistics Handbook 2022-23, Horticulture Innovation Australia Ltd and Fresh Logic, P 307 – 311; 2024.

4 Australian Bureau of Statistics; Agricultural Commodities Australia 2021-22; sourced courtesy Peter Philp, Philp Hort Consultants; 2023.

5 Australian Horticulture Statistics Handbook 2022-23, Horticulture Innovation Australia Ltd and Fresh Logic; P309; 2024.

6 SA Minister of Agriculture; Annual Report; 1943-44; P 5; 1944.

7 SA Minister of Agriculture; Annual Report; 1913-14; P 32; 1914.

8 SA Minister of Agriculture, Annual Report, 1940-41; P 9; 1941.

9 SA Minister of Agriculture; Annual Report; 1944-45; P 8; 1945.

10 Webber G D; Report of the Working Party for Review of the Potato Marketing Act; SA Department of Agriculture; March 1985.

11 SA Minister of Agriculture; Annual Report; 1908-09; P 36; 1909

12 SA Minister of Agriculture; Annual Report; 1909-10; P 35; 1910.

13 SA Minister of Agriculture; Annual Report; 1911-12; P 31; 1912.

14 Chief Plant Health Officer; Potato Cyst Nematode Management Policy; Agriculture Victoria; Dec 2021; P 4.

15 Mulcahy R; Finalisation of the PCN National Management Plan; AUSVEG Ltd; Project No PT10024; May 2011.

16 Dillard H R; Wicks T J; Philp B W; Reducing Pesticide Use on Potato Crops – a strategy for research and extension; SA Dept of Primary Industry; Technical Report No 207; 1993.

17 Thomas B and Thomas G S; Guidelines foe Management of Land Associated with Centre Pivots; South Australian Murray Darling Basin NRM Board; Oct 2008.

18 SA Minister of Agriculture; Annual Report; 1908-09; P 36; 1909.

19 SA Minister of Agriculture; Annual Report; 1928-29; P 25; 1929.

Publications and further reading

In addition to the references above, below are numerous reports, publications, web sites, and other items of information that have provided general background material for preparation of this South Australian potato industry article.

Adam D B; Potato Diseases in South Australia; SA Department of Agriculture; Bulletin No 383; 1942.

AuSPICA; Australian Seed Potato Industry Certification Authority, seed potato certification schemes; 2020; www.auspica.org.au

Beaumont C H; Potato Growing; SA Department of Agriculture; Bulletin No 235; 1929.

Dillard H R, Wicks T J, Philp B W; Reducing Pesticide Use on Potato Crops – a Strategy for Research and Extension; SA Department of Agriculture; Technical Report No 207; 1993.

Feddersen H D; Potato Research in Germany, Holland, UK, Switzerland, and USA; SA Department of Agriculture; Report on an Overseas Trip; 1966.

Feddersen H D; Potato Varieties for South Australia; SA Department of Agriculture Leaflet No 3973; 1971.

Feddersen H D and Nitschke R A; Potatoes for the Housewife; SA Department of Agriculture Special Bulletin No 10.72.; 1972.

Feddersen H D; On farm Storage of Potatoes – cold storage on the farm of potatoes using controlled ventilation as the means of temperature control 1967 – 1972; SA Department of Agriculture; Horticulture Branch Report Series 5 No 1/73; 1973.

Feddersen H D; The Potato Industry in South Australia; SA Department of Agriculture; Special Bulletin No 2/73; 1973.

Feddersen H D; Potato Growing in South Australia; SA Department of Agriculture Bulletin No 19.74 (previously Leaflet No 3539); 1974.

Fresh Logic; Australian Horticulture Statistics Handbook – Potatoes 2022-23; Hort Innovation; P 307-311; 2024. Link to this publication below: