Remote asset management – Arcoflex

Arcoflex offers a wide range of remote monitoring and control of agricultural assets, including irrigation, power and electric fences.

Benefits

Benefits

Arcoflex has taken a custom approach to automate the farm’s existing:

- flood irrigation pump

- electric fence energiser

- irrigation channel depth monitoring.

It enables the pump to be primed remotely to start the flood irrigation. This provides a significant time-cost saving to get water flowing faster, without staff having to travel to the site. It also reduces water use, as irrigation can be managed effectively at night with little evapotranspiration.

The electric fence is remotely operated and monitored, which lowers stock management risks in knowing when and where the electric fence breaks down.

How it works

Arcoflex is adaptable to most farm assets. It allows you to monitor up to 30 sensors and control up to 10 devices.

The technology uses a combination of flow monitors, electric butterfly valves and water level sensors. A global positioning system maps the geographical site of each hardwired sensor.

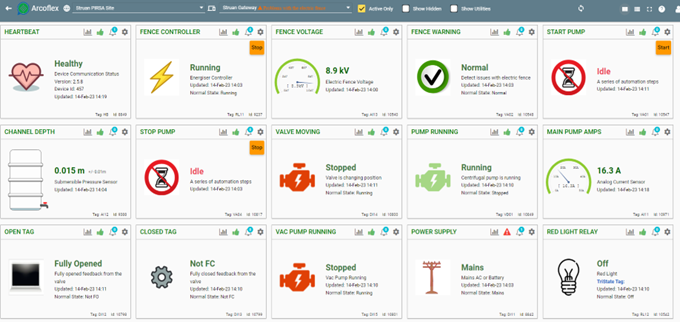

The dashboard is accessed via app, or online through a web browser on your mobile, tablet or computer. Real-time notifications can be sent by text or email, as well as onsite visual alarms.

Dashboard and control system for Arcoflex remote monitoring

Installation and power

Arcoflex can be installed by a local technician from the company, or a qualified electrician.

Power is supplied by mains power with a battery backup.

Connectivity requirements

Arcoflex connects using built-in 3G or 4G services.

Local Wi-Fi is needed for some remote assets.

Pricing model

The Arcoflex standard gateway has an upfront cost, with additional costs for installation and monthly monitoring.

Producer case study

Producer case study

Nick D’Avoine is the program manager at Farming the Sky – an initiative to decarbonise agriculture in Australia and abroad. He works closely with dairy farms to monitor and reduce methane emissions.

Nick discovered the Arcoflex water monitoring technologies while installing solar-powered centre pivots to replace diesel models. The company has a range of monitoring solutions, including custom jobs as needed. Nick requested that Arcoflex design a system for monitoring methane levels in dairy sheds over time.

This equipment is simple to operate, and the data can be used to calculate how much methane is being produced per cow. Nick has found the technology to be reliable, providing accurate data that cannot be easily manipulated.

'Current methodology for monitoring methane emissions on farm, as recognised by the Australian Government Clean Energy Regulator, requires lab testing. That can be unpredictable and prone to error,' says Nick. 'This new method is much harder to dispute. Farmers can use this tech to prove their methane levels and qualify for carbon credit. It acts as risk mitigation and can provide a secure revenue stream.'

Arcoflex methane monitoring also qualifies under the internationally recognised VERRA Verified Carbon Standard. For companies like the Fleurieu Milk Company, who have been working with Nick and Arcoflex’s product, this can help them expand and gain status as a premium global milk brand.

One of Nick’s projects may have implications for the entire industry. It uses Arcoflex to monitor methane in dairy farms, with Asparagopsis microalgae in cattle feed. This technology will help verify if real-world environments match the levels reported in labs, corroborating it as an environmentally sustainable option.

See it in action

To view Arcoflex, contact the AgTech Extension Officer at Struan and Kybybolite demonstration farm.

Struan AgTech field day demonstration

Contact vendor

Geoff Schaller – Arcoflex

Email: geoff@arcoflex.com.au